TiC ceramic with laminated structure, and preparation method of TiC ceramic

A laminated structure and ceramic technology, applied in the field of TiC ceramics with a laminated structure and its preparation, can solve problems such as interface cracks or voids, poor chemical compatibility and wettability, and reduce the performance of carbon-titanium composite materials. Good ductility, the effect of overcoming poor chemical compatibility and wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

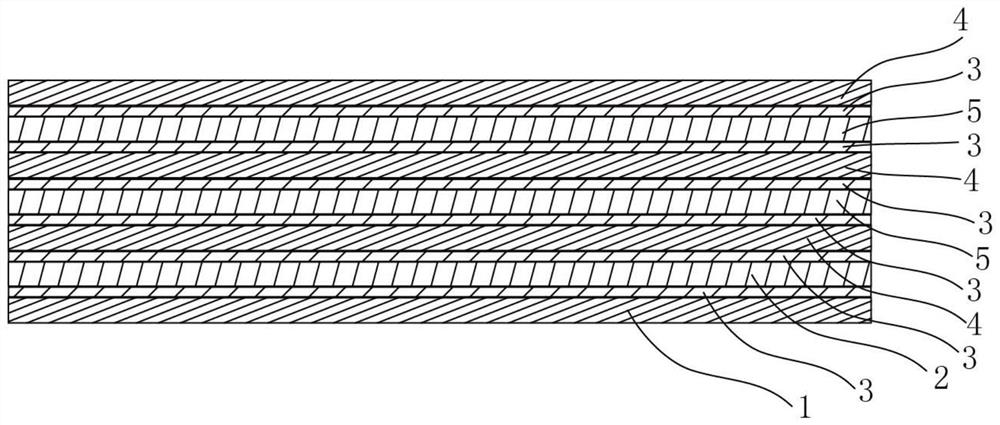

[0041] The present invention also provides a method for preparing TiC ceramics with a laminated structure, comprising the following steps:

[0042] Substrate printing step: use a specific double-beam 3D printing device to print titanium nanomaterials to form a first titanium nanolayer 1, and use the Ti layer formed by the first titanium nanolayer 1 as a substrate.

[0043] Laminate printing steps: First, use a specific double-beam 3D printing device to print the first carbon nano-layer 2 on the first titanium nano-layer 1 to form a C layer on the substrate; secondly, use a specific double-beam 3D printing equipment The 3D printing equipment prints the second titanium nanolayer 4 on the first carbon nanolayer 2 with titanium nanomaterials to form a Ti layer on the C layer.

[0044] Multi-layer printing steps: First, use a specific double-beam 3D printing device to print the second titanium nano-layer 5 on the second titanium nano-layer 4 to form a C layer on the Ti layer; secon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com