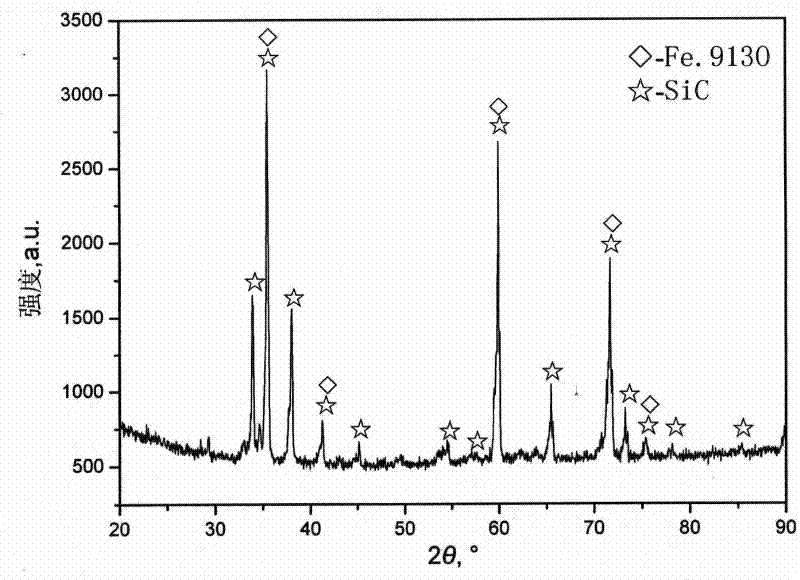

Method for preparing ferric oxide ceramic thin film on the surface of three-dimensional network silicon carbide

A technology of network silicon carbide and ceramic film, applied in the field of materials, to achieve the effect of simple preparation method, cheap raw materials, and excellent thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Ferric nitrate is mixed with 0.1mol / L ferric nitrate solution, and urea is added in solution, and the add-on of urea is urea in molar ratio: iron ion=2: 1; The solution that will obtain is heated up under stirring condition, and stirring speed is 100rpm , heat up to 40°C, keep warm for 25min, then cool to room temperature, let stand for 7h, then heat to 70°C, keep warm for 40min to obtain iron-containing sol.

[0029] The three-dimensional network silicon carbide is immersed in the iron-containing sol under vacuum conditions for 30 minutes, then taken out and dried at room temperature for 25 minutes, heated to 55°C for 10 minutes, heated to 75°C for 40 minutes, and the coating is completed.

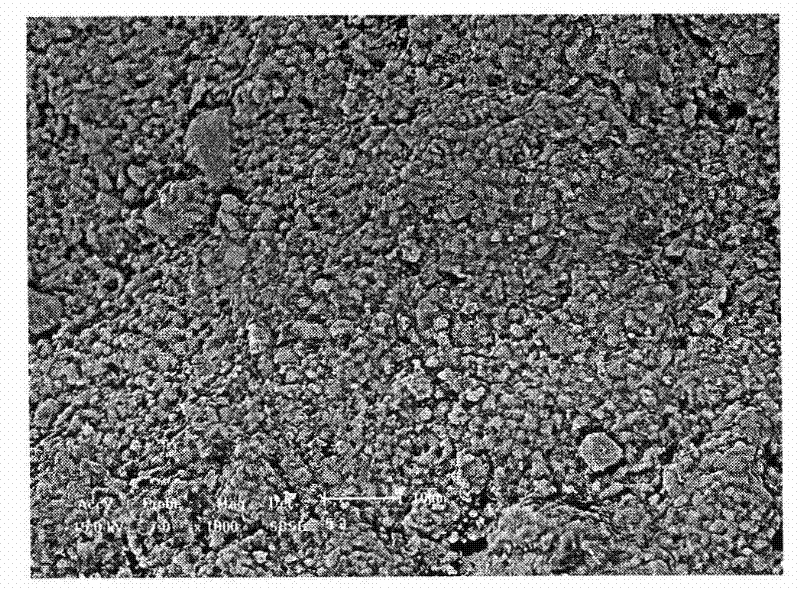

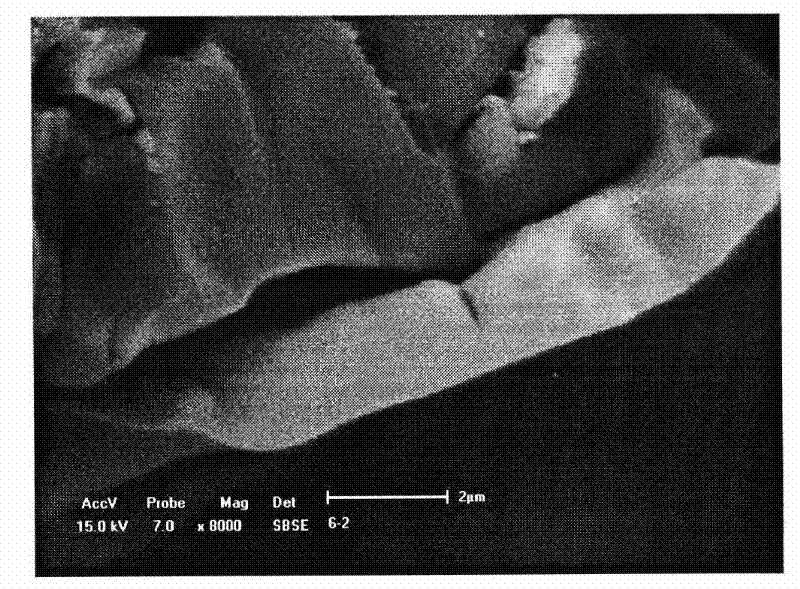

[0030] The three-dimensional network silicon carbide coated with iron-containing sol was heated to 120°C for 80 minutes, 250°C for 170 minutes, and 400°C for 200 minutes; the heating rate was 2°C / min. A uniform and dense iron oxide film is obtained on the surface of the three-dimen...

Embodiment 2

[0032] Ferric nitrate is mixed with 0.3mol / L ferric nitrate solution, and urea is added in solution, and the add-on of urea is urea in molar ratio: iron ion=3: 1; The solution that will obtain is heated up under stirring condition, and stirring speed is 160rpm , heat up to 50°C, keep warm for 30min, then cool to room temperature, let stand for 7.5h, then heat to 80°C, keep warm for 30min to obtain iron-containing sol.

[0033] The three-dimensional network silicon carbide is immersed in the iron-containing sol under vacuum conditions for 25 minutes, then taken out and dried at room temperature for 15 minutes, heated to 50°C for 15 minutes, heated to 85°C for 30 minutes, and the coating is completed.

[0034] The three-dimensional network silicon carbide coated with iron-containing sol was heated to 140°C for 60 minutes, 300°C for 150 minutes, and 450°C for 170 minutes; the heating rate was 5°C / min. A uniform and dense iron oxide film is obtained on the surface of the three-dim...

Embodiment 3

[0036] Ferric nitrate is mixed with 0.5mol / L ferric nitrate solution, and urea is added in solution, and the add-on of urea is urea in molar ratio: iron ion=4: 1; The solution that will obtain is heated up under stirring condition, and stirring speed is 200rpm , heated up to 55°C, kept warm for 35min, then cooled to room temperature, stood still for 6.5h, then heated to 95°C, kept warm for 20min, and iron-containing sol was obtained.

[0037] The three-dimensional network silicon carbide is immersed in the iron-containing sol under vacuum conditions for 20 minutes, then taken out and dried at room temperature for 10 minutes, heated to 46°C for 25 minutes, heated to 90°C for 20 minutes, and the coating is completed.

[0038] The three-dimensional network silicon carbide coated with iron-containing sol was heated to 180°C for 50 minutes, 340°C for 100 minutes, and 600°C for 150 minutes; the heating rate was 8°C / min. A uniform and dense iron oxide film is obtained on the surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com