Method for preparing titanium-iron particle reinforced hydroxyapatite-based bioceramic material

A bioceramic material, hydroxyapatite technology, applied in the field of materials, can solve the problem of high cost, achieve the effects of low cost, improved flexural strength, and easy industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

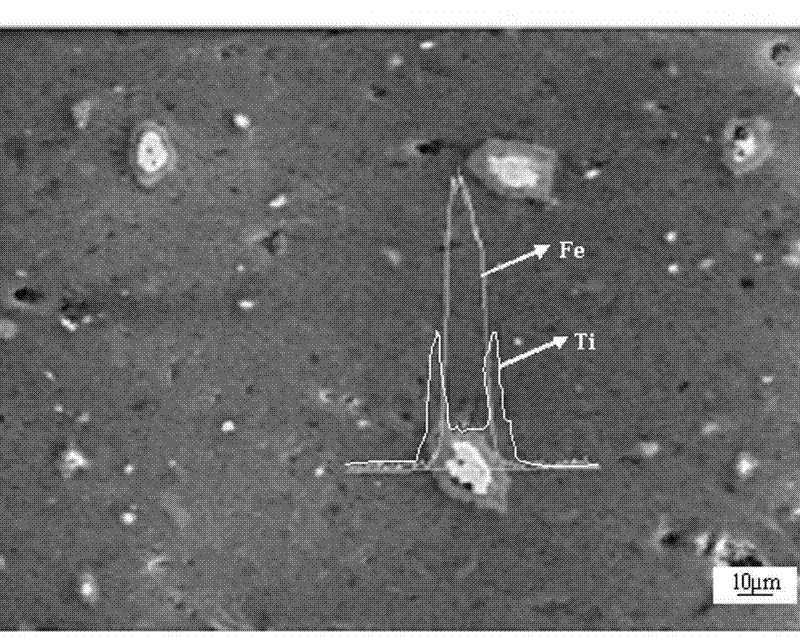

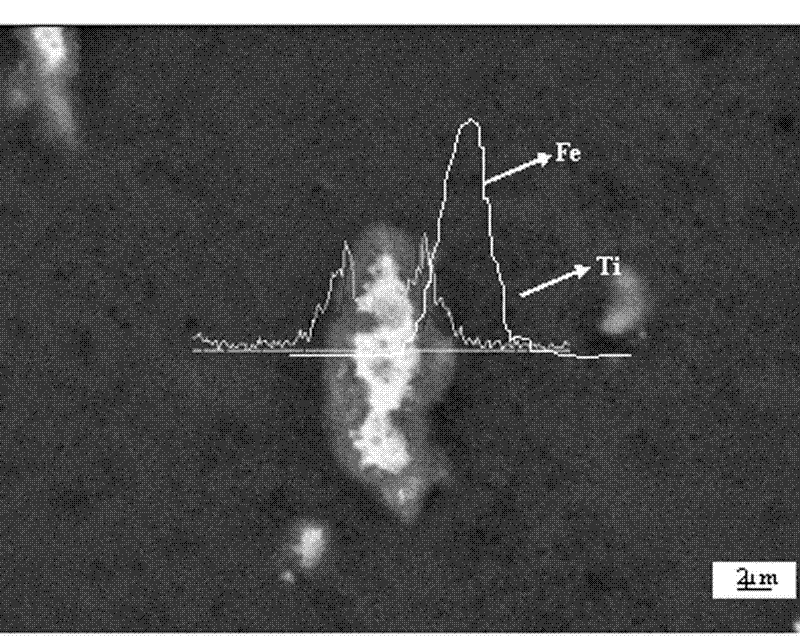

Image

Examples

Embodiment 1

[0028] Mix titanium powder and iron powder with a particle size of 300~500 mesh, the titanium powder accounts for 50% of the total weight of all materials, and then use absolute ethanol as the medium to mix and grind until the particle size of all materials is 1~5μm. into composite powder;

[0029] Mix the composite powder with HA powder with a particle size of 80~200mm to make a mixed powder. The composite powder accounts for 5% of the total weight of the mixed powder, and then the mixed powder is mixed evenly with anhydrous ethanol as a medium; Dry at 5°C to remove ethanol to obtain HA / Ti-Fe powder;

[0030] The HA / Ti-Fe powder was formed by cold isostatic pressing under the condition of 200MPa, and the holding time was 5 minutes to make a green body;

[0031] The green body was placed in a vacuum muffle furnace and sintered under the condition of a vacuum degree of 10-50Pa, the sintering temperature was 900°C, and the holding time was 300min to obtain a hydroxyapatite-base...

Embodiment 2

[0034] Mix titanium powder and iron powder with a particle size of 300~500 mesh, titanium powder accounts for 60% of the total weight of all materials, and then use absolute ethanol as the medium to mix and grind until the particle size of all materials is 1~5μm. into composite powder;

[0035] Mix the composite powder with HA powder with a particle size of 80~200mm to make a mixed powder. The composite powder accounts for 10% of the total weight of the mixed powder, and then the mixed powder is mixed evenly with anhydrous ethanol as a medium; Dry at 5°C to remove ethanol to obtain HA / Ti-Fe powder;

[0036] The HA / Ti-Fe powder was formed by cold isostatic pressing under the condition of 200MPa, and the holding time was 5 minutes to make a green body;

[0037] The green body is placed in a vacuum muffle furnace and sintered under the condition of a vacuum degree of 10-50Pa, the sintering temperature is 1000°C, and the sintering time is 200min to obtain a hydroxyapatite-based b...

Embodiment 3

[0040] Mix titanium powder and iron powder with a particle size of 300-500 mesh, titanium powder accounts for 70% of the total weight of all materials, and then use absolute ethanol as a medium to mix and grind until the particle size of all materials is 1-5 μm. into composite powder;

[0041] Mix the composite powder with HA powder with a particle size of 80~200mm to make a mixed powder. The composite powder accounts for 15% of the total weight of the mixed powder, and then the mixed powder is mixed evenly with anhydrous ethanol as a medium; Dry at 5°C to remove ethanol to obtain HA / Ti-Fe powder;

[0042] Put the HA / Ti-Fe powder into the mold and perform unidirectional compression molding under the condition of 200MPa to make a biscuit;

[0043] The green body is placed in a vacuum muffle furnace and sintered under the condition of a vacuum degree of 10-50Pa, the sintering temperature is 1100°C, and the sintering time is 100min to obtain ferro-titanium particle-reinforced hy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Fracture toughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com