Ti/X metal ceramic with laminated structure and preparation method of Ti/X metal ceramic

A technology of cermet and laminated structure, applied in the direction of additive processing, etc., can solve the problems of poor chemical compatibility and wettability, thermodynamic mismatch, large difference in thermal expansion coefficient, etc., to overcome chemical compatibility and good ductility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

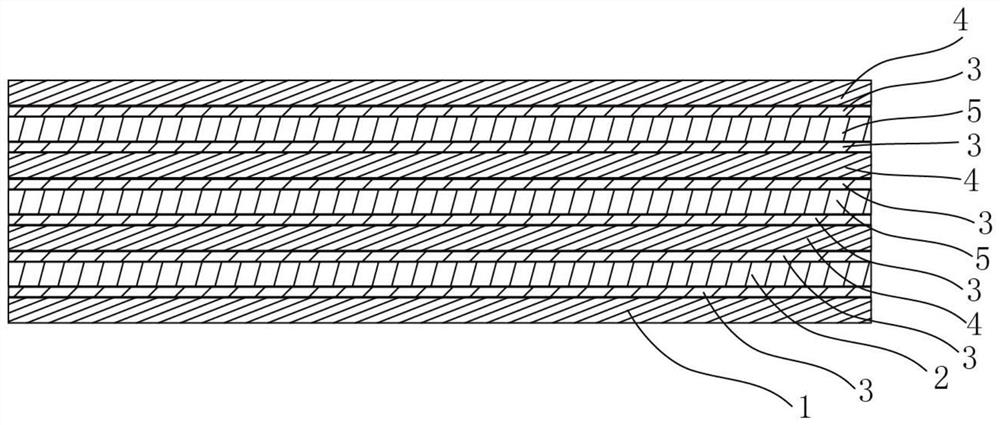

[0044] The present invention also provides a method for preparing a Ti / X cermet with a laminated structure, comprising the following steps:

[0045] Substrate printing step: use a specific double-beam 3D printing device to print titanium nanomaterials to form a first titanium nanolayer 1, and use the Ti layer formed by the first titanium nanolayer 1 as a substrate.

[0046] Laminate printing steps: First, use a specific double-beam 3D printing device to print the first cermet material nano-layer 2 on the first titanium nano-layer 1 to form an X-layer on the substrate; secondly, use a specific The double-beam 3D printing equipment prints the second titanium nanolayer 4 on the first cermet material nanolayer 2 with titanium nanomaterials to form a Ti layer on the X layer.

[0047] Multi-layer printing steps: First, use a specific double-beam 3D printing device to print the second titanium nano-layer 5 on the second titanium nano-layer 4 to form an X layer on the Ti layer; second...

Embodiment 2

[0083] The Ti / AlN ceramics with laminated structure of the present embodiment, such as figure 1 As shown, it includes Ti layer, Ti-AlN transition layer, AlN layer, Ti-AlN transition layer, Ti layer... Ti-AlN transition layer, AlN layer, Ti-AlN transition layer, Ti layer from bottom to top.

[0084] The preparation method of the Ti / AlN ceramic of the present embodiment comprises the following steps:

[0085] 1) Conveying the titanium nanopowder material to the printing beam nozzle of the dual-beam 3D printing device;

[0086] 2) Drive the printing beam nozzle to move according to the preset trajectory and eject titanium nanomaterials to form the first titanium nanolayer 1;

[0087] 3) transporting the AlN nano powder to the printing beam nozzle, driving the printing beam nozzle to move according to a preset trajectory and ejecting the AlN nano powder to form the first AlN nano layer on the first titanium nano layer 1;

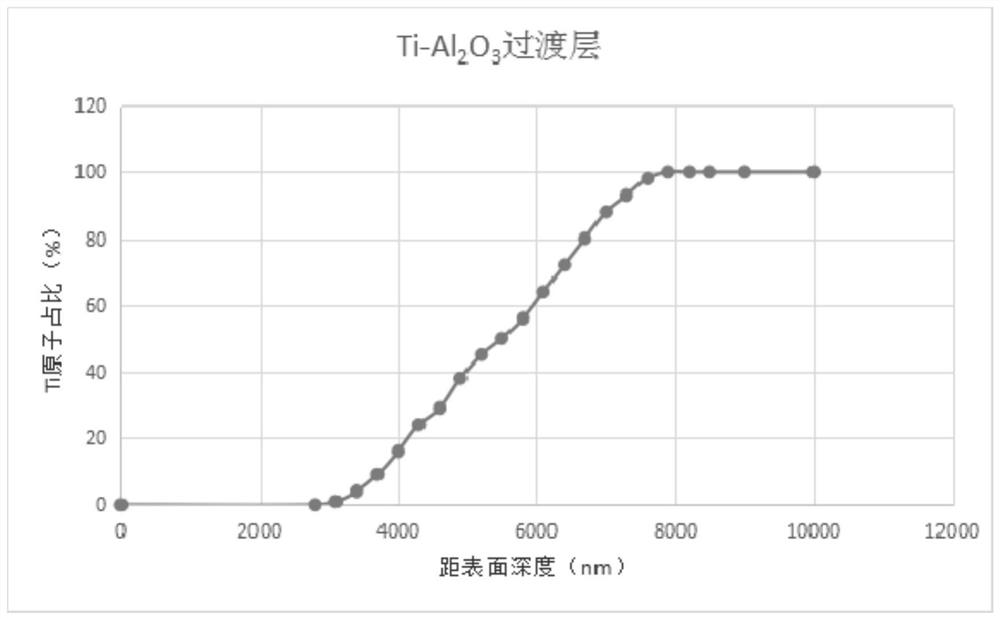

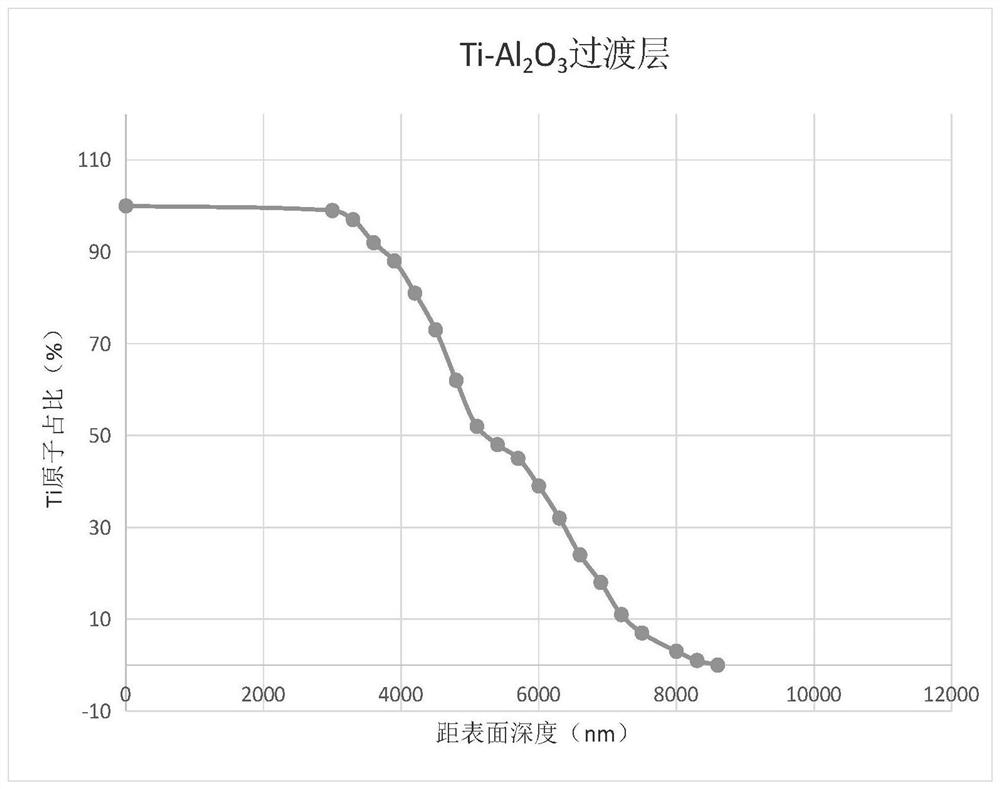

[0088] 4) The interface between the first titanium layer...

Embodiment 3

[0098] The Ti / SiC ceramics with laminated structure of the present embodiment, such as figure 1 As shown, it includes Ti layer, Ti-SiC transition layer, SiC layer, Ti-SiC transition layer, Ti layer... Ti-SiC transition layer, SiC layer, Ti-SiC transition layer, Ti layer from bottom to top.

[0099] The preparation method of the Ti / SiC ceramic of the present embodiment comprises the following steps:

[0100] 1) Conveying the titanium nanopowder material to the printing beam nozzle of the dual-beam 3D printing device;

[0101] 2) Drive the printing beam nozzle to move according to the preset trajectory and eject titanium nanomaterials to form the first titanium nanolayer 1;

[0102] 3) Transporting the SiC nano powder to the printing beam nozzle, driving the printing beam nozzle to move according to a preset trajectory and ejecting the SiC nano powder to form a first SiC nano layer on the first titanium nano layer 1;

[0103] 4) The interface between the first titanium layer 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com