Modified graphene-reinforced aluminum matrix composite material and preparation method thereof

A technology for strengthening aluminum-based and composite materials, applied in the field of aluminum-based composite materials, can solve the problems of not considering the interface between graphene and aluminum alloy, and achieve the effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

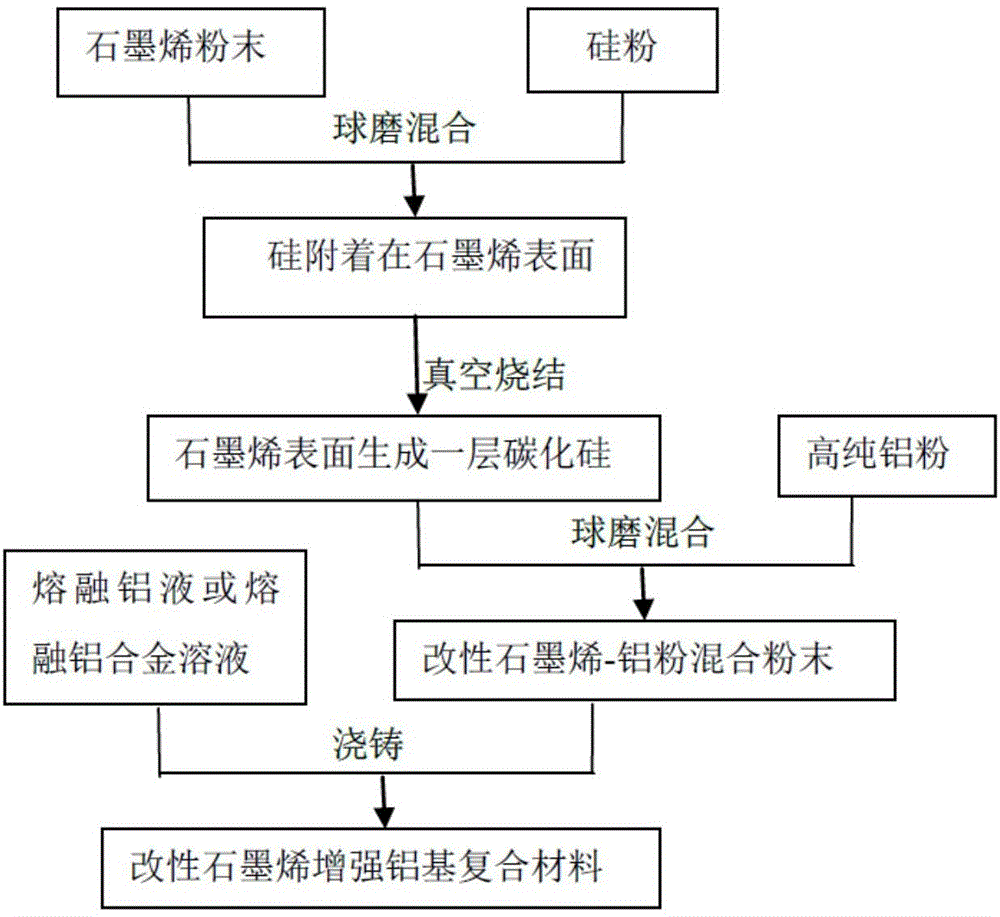

[0031] Depend on figure 1 , the invention discloses a method for preparing a modified graphene-reinforced aluminum-based composite material, comprising the following steps:

[0032] ①Put graphene powder, silicon powder, grinding balls, and stearic acid in a ball mill, and feed liquid nitrogen into the ball mill. After the liquid nitrogen immerses all the balls, perform ball milling to obtain a mixture of graphene powder and silicon powder. powder. In this step, the weight ratio of silicon powder and graphene powder is: 0.4-0.6:1, the weight ratio of grinding ball and mixed powder is 5-10:1, the speed of ball mill is 20-100rpm, and the time for ball milling is 3~8h.

[0033] Among them, stearic acid is a solid surfactant, which can attach to the unsaturated broken bonds on the surface of powder particles, reduce the interfacial energy between powder particles, thereby producing a grinding aid effect on the pulverization of powder particles, which is beneficial to the powder ...

Embodiment 1

[0047] ①Put silicon powder (70g), graphene powder (180g), balls and stearic acid in a ball mill, fill with liquid nitrogen, and start ball milling when all balls are submerged in liquid nitrogen. The weight ratio of balls to mixed powder is 10, the speed of the ball mill is 20rpm, and the ball mill is 8h.

[0048] ② Dry the obtained mixed powder of silicon powder and graphene in a vacuum drying oven at a temperature of 90° C. for 2 hours.

[0049] ③ Place the dried mixed powder in a vacuum sintering furnace and sinter at 1300°C for 1 hour.

[0050] ④ Mix the sintered modified graphene (250g), high-purity aluminum powder (750g), balls and stearic acid in a ball mill, fill it with liquid nitrogen and ball mill for 2 hours, and mix the balls with the modified graphene-aluminum The weight ratio of powder to powder mixture is 10, and the rotational speed of the ball mill is 50 rpm.

[0051] ⑤ Dry the finally obtained modified graphene-aluminum powder mixed powder in a vacuum dryi...

Embodiment 2

[0055] ① Put silicon powder (70g), graphene powder (150g), balls and stearic acid in a ball mill, fill it with liquid nitrogen, and start ball milling when all the balls are submerged in liquid nitrogen. The weight ratio of balls to mixed powder 8, the speed of the ball mill is 60rpm, and the ball mill is 5h.

[0056] ②Dry the obtained mixed powder of silicon powder and graphene in a vacuum drying oven at a temperature of 100° C. for 1 h.

[0057] ③ Place the dried mixed powder in a vacuum sintering furnace and sinter at 1200°C for 1.5h.

[0058] 4. Mix the sintered modified graphene (220g), high-purity aluminum powder (780g), balls and stearic acid in a ball mill, fill it with liquid nitrogen and ball mill for 3 hours, and mix the balls with the modified graphene-aluminum The weight ratio of the powder mixed powder is 8, and the rotational speed of the ball mill is 20 rpm.

[0059] ⑤ Dry the finally obtained modified graphene-aluminum powder mixed powder in a vacuum drying ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com