A negative electrode material for pyrolytic carbon battery embedded with tin-based oxide and its preparation method

A battery negative electrode, pyrolysis carbon technology, applied in the direction of battery electrodes, active material electrodes, negative electrodes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

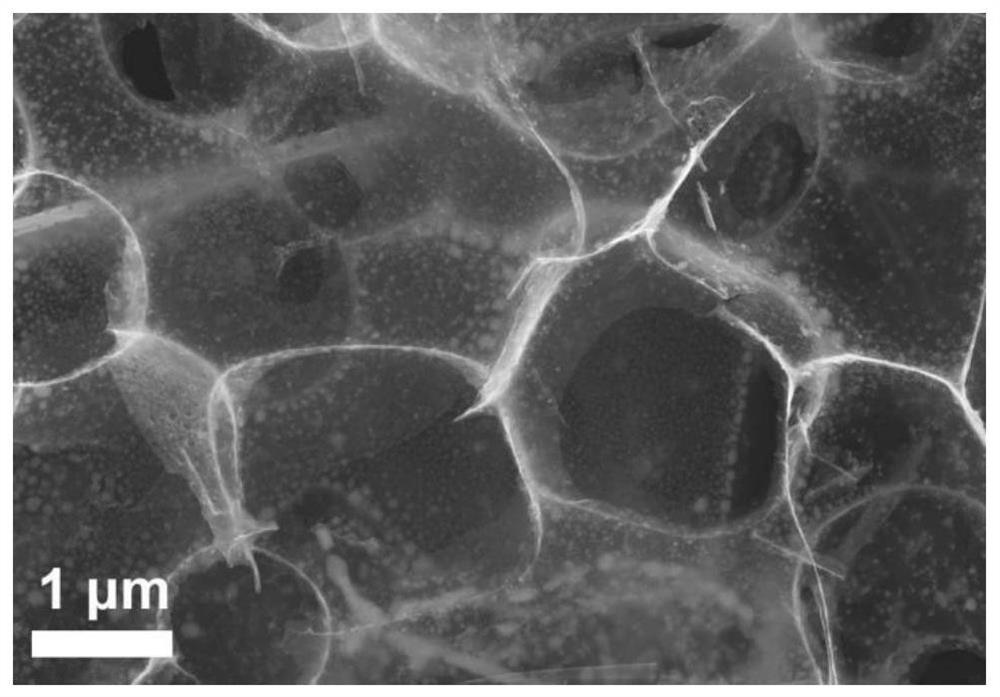

[0052] A pyrolytic carbon battery negative electrode material embedded with tin-based oxide, the material is composited by carbon-coated nano-tin-based oxide particles and pyrolytic carbon, and the carbon-coated nano-tin-based oxide particles are evenly embedded in the Embedded on pyrolytic carbon. The particle diameter of the nano-tin-based oxide particles is 2-5 nm. The thickness of the carbon coating layer is 1-5 nm. The pyrolytic carbon is a three-dimensional porous network carbon structure.

[0053] A preparation method of a pyrolytic carbon battery negative electrode material embedded with a tin-based oxide, comprising the following steps:

[0054] Step 1, Mix and Dry:

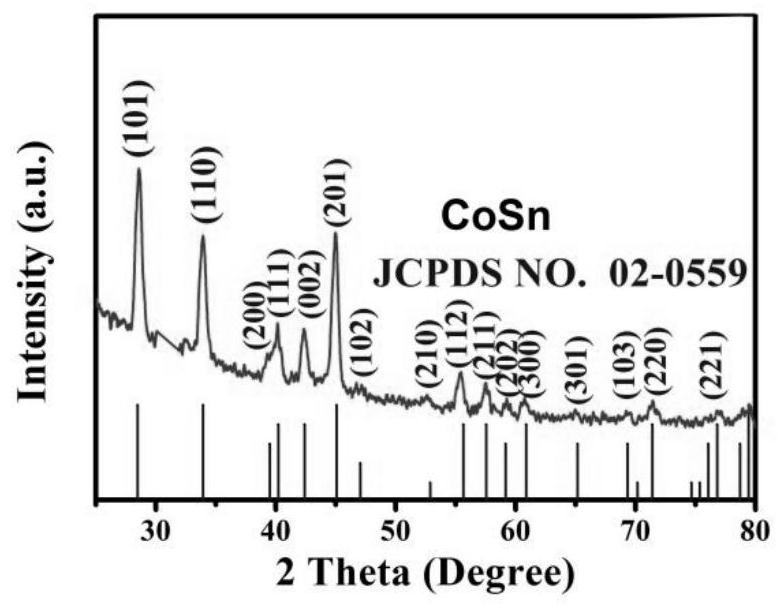

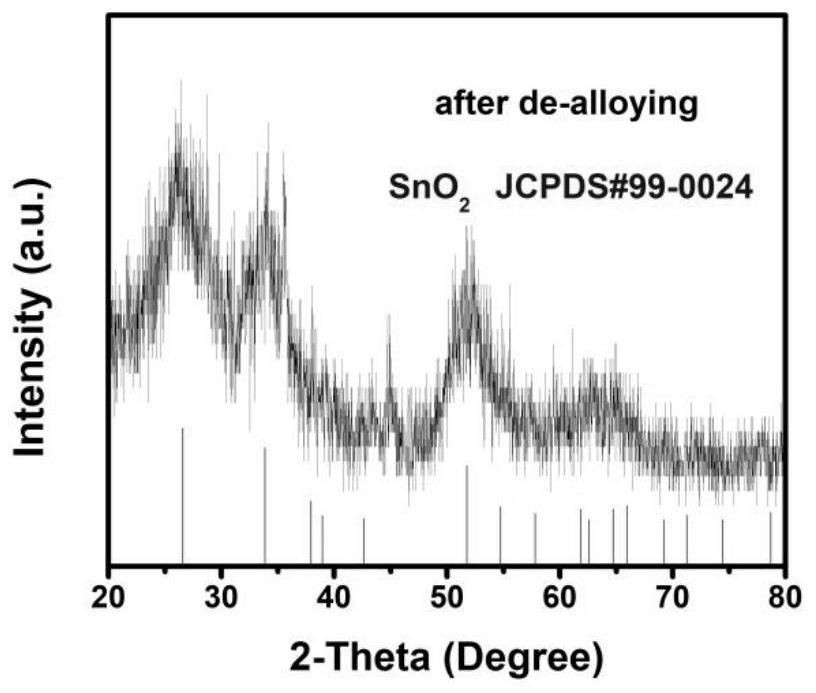

[0055] (1) Dissolve NaCl (20.64g), citric acid (2.5g), stannous chloride (0.244g), and cobalt nitrate (0.322g) with 75mL of deionized water, and the magnetic stirring time is 8h to obtain a solution;

[0056] (2) Freeze the solution in a refrigerator at -15°C, and after completely freezing, use a fre...

Embodiment 2

[0066] A pyrolytic carbon battery negative electrode material embedded with tin-based oxide, the material is composited by carbon-coated nano-tin-based oxide particles and pyrolytic carbon, and the carbon-coated nano-tin-based oxide particles are evenly embedded in the Embedded on pyrolytic carbon. The particle diameter of the nano-tin-based oxide particles is 2-5 nm. The thickness of the carbon coating layer is 1-5 nm. The pyrolytic carbon is a three-dimensional porous network carbon structure.

[0067] A preparation method of a pyrolytic carbon battery negative electrode material embedded with a tin-based oxide, comprising the following steps:

[0068] Step 1, Mix and Dry:

[0069] (1) NaCl (20.7g), citric acid (2.5g), stannous chloride (0.185g), and copper nitrate (0.234g) were dissolved in 75mL of deionized water, and the magnetic stirring time was 10h to obtain a solution;

[0070] (2) Freeze the solution in a refrigerator at -15 °C, and after completely freezing, use...

Embodiment 3

[0080] A pyrolytic carbon battery negative electrode material embedded with tin-based oxide, the material is composited by carbon-coated nano-tin-based oxide particles and pyrolytic carbon, and the carbon-coated nano-tin-based oxide particles are evenly embedded in the Embedded on pyrolytic carbon. The particle diameter of the nano-tin-based oxide particles is 2-5 nm. The thickness of the carbon coating layer is 1-5 nm. The pyrolytic carbon is a three-dimensional porous network carbon structure.

[0081] A preparation method of a pyrolytic carbon battery negative electrode material embedded with a tin-based oxide, comprising the following steps:

[0082] Step 1, Mix and Dry:

[0083] (1) NaCl (20.64g), citric acid (2.5g), stannous chloride (0.24g) and nickel nitrate (0.36g) were dissolved in 75mL deionized water, and the magnetic stirring time was 5h to obtain a solution;

[0084] (2) Freeze the solution in a refrigerator at -15 °C, and after completely freezing, use a fre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com