Porous silicon and carbon mixed anode plate and lithium ion secondary battery comprising same

A hybrid anode and porous anode technology, applied in secondary batteries, battery electrodes, electrode carriers/current collectors, etc., can solve the problems of large volume expansion of lithium ion secondary batteries, reduced battery volume energy density, and reduced cycle performance, etc. Achieve the effect of reducing strength, avoiding separation, and reducing volume expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

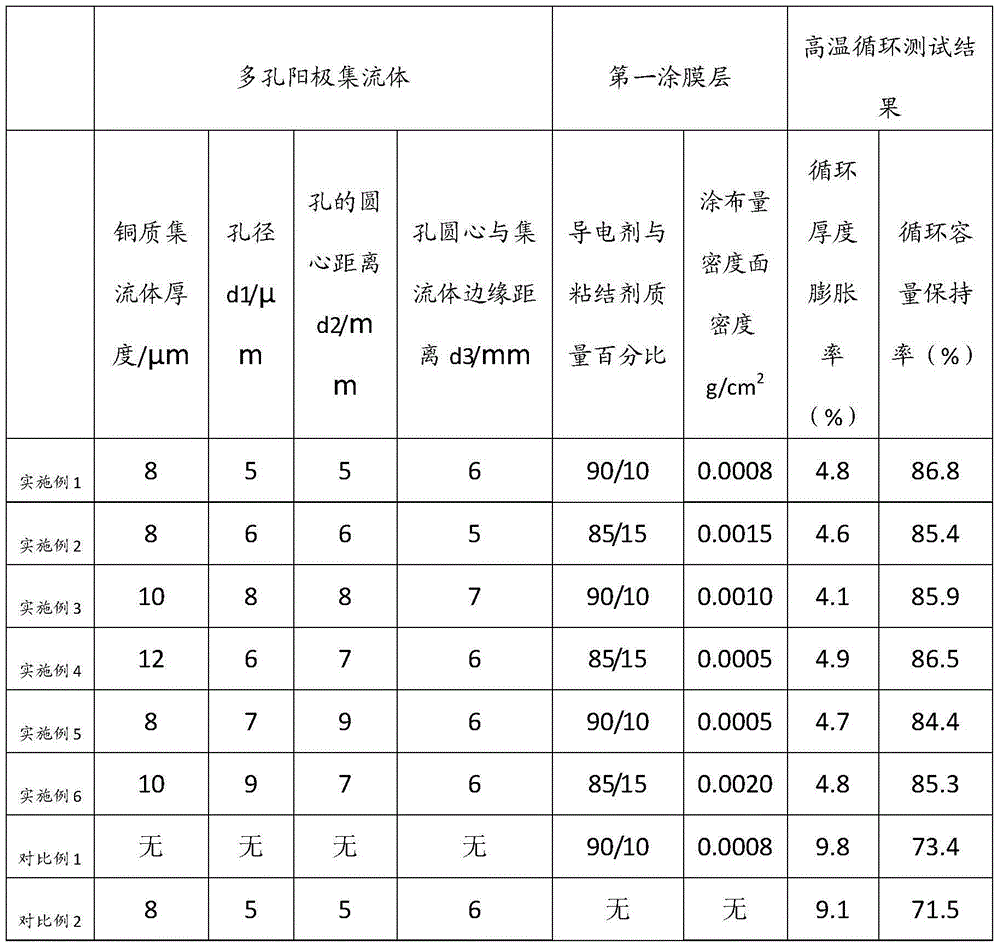

Embodiment 1

[0018] Preparation of lithium ion secondary battery negative electrode of the present invention:

[0019] Lithium cobalt oxide, conductive agent SuperP, and binder PVDF are mixed uniformly according to the mass percentage of 96:2.0:2.0 to make a certain viscosity lithium ion secondary battery positive electrode slurry, which is coated on the current collector aluminum foil. 0.0194g / cm 2 , after drying at 85°C, cold pressing; then trimming, cutting, and slitting, and drying at 85°C for 4 hours under vacuum conditions after slitting, and welding the tabs to make lithium-ion di secondary battery cathode.

[0020] The preparation of lithium-ion secondary battery anode pole piece is divided into three steps:

[0021] The first step: perforated current collector

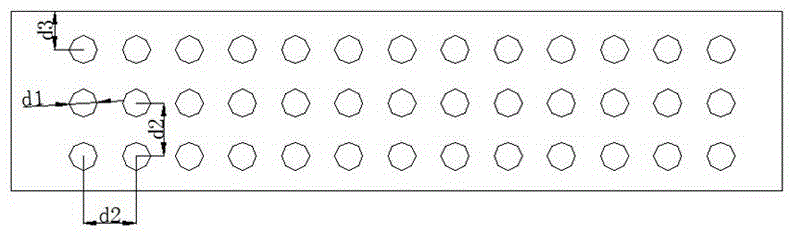

[0022] like figure 1 As shown, a copper current collector with a thickness of 8 μm is selected, and the current collector is perforated. The shape of the through hole of the porous anode current collector sheet is cir...

Embodiment 2

Embodiment 3

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com