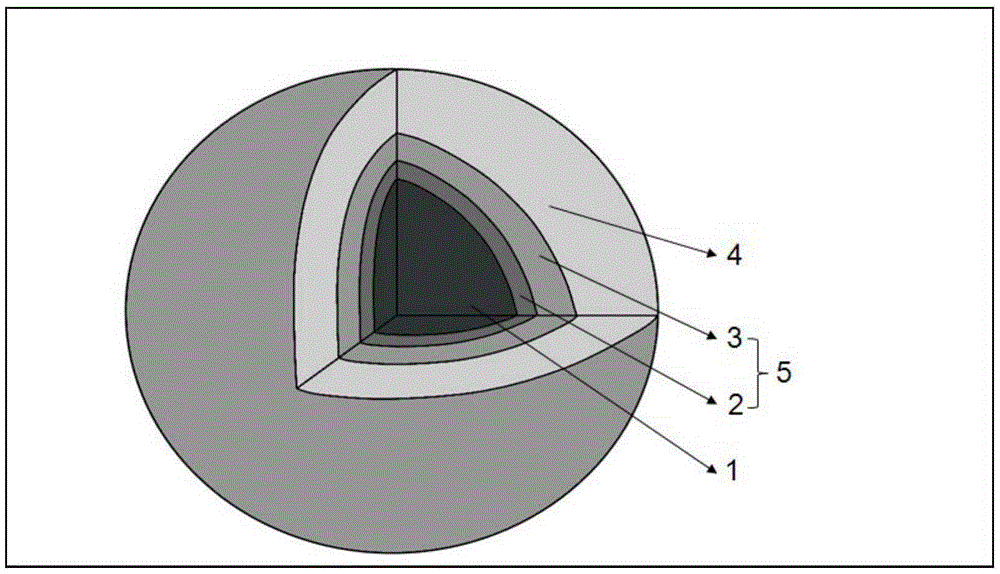

Composite silicon negative electrode material, and preparation method and application thereof

A silicon negative electrode and nano-composite technology, applied in negative electrodes, electrode manufacturing, chemical instruments and methods, etc., can solve problems such as difficult volume expansion, degradation of negative electrode material cycle performance, difficult preparation of active silicon layers, etc., to achieve a simple and easy preparation process control, improve cycle performance, and avoid direct contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

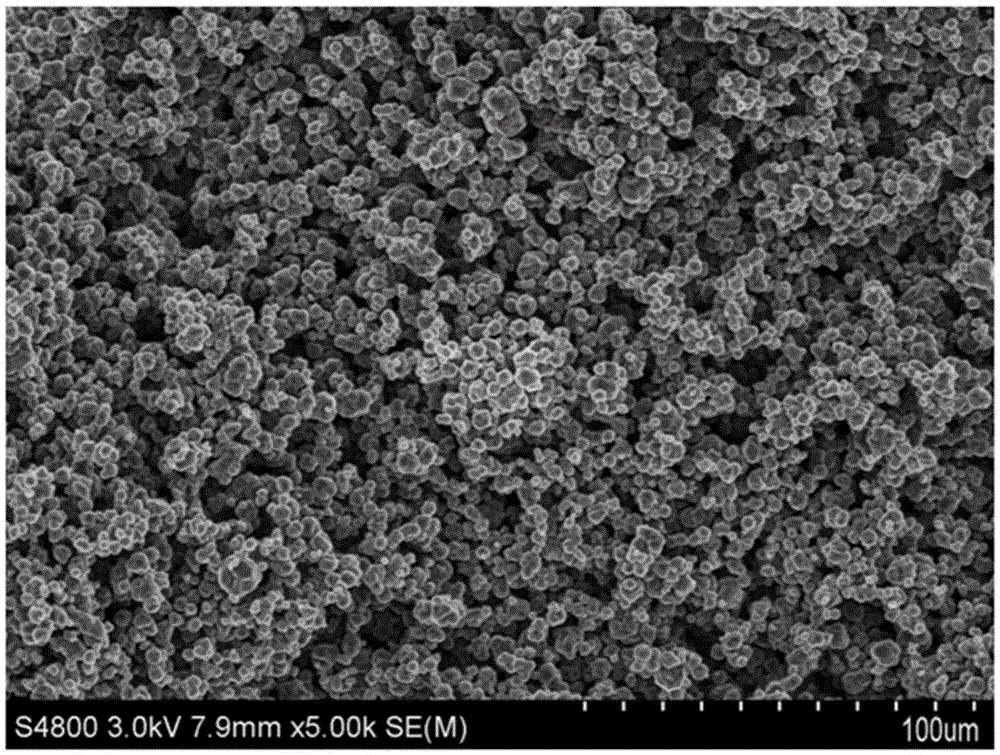

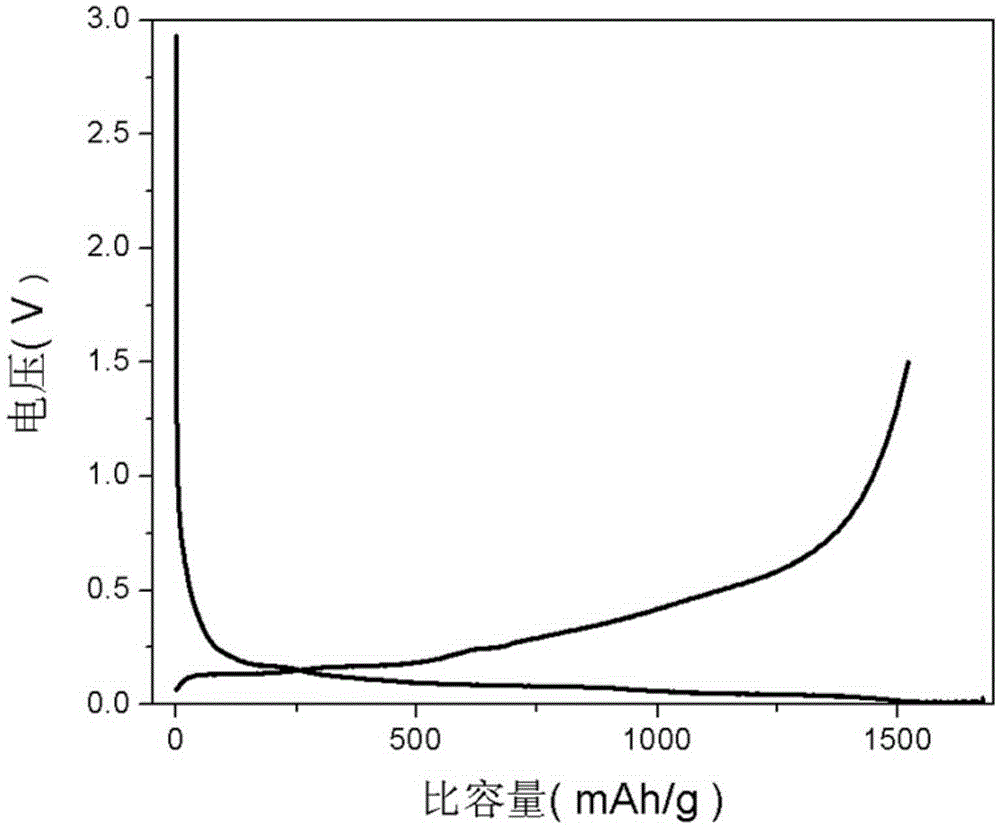

[0060] A composite silicon negative electrode material prepared by the following method:

[0061] (1) Select silicon powder with a median particle size of 50-80nm as nano-silicon, place it in a rotary furnace with a rotating speed of 20r / min, and feed argon gas with a volume ratio of 1:0.5 at a gas flow rate of 0.5L / min. Oxygen mixed gas, heat treatment at 500°C for 1 hour, to obtain primary heat treatment silicon powder;

[0062] Mix primary heat-treated silicon powder, bismuth powder and tin powder at a mass ratio of 100:5:5 and put them into a high-energy ball mill, and put 0.5mm zirconium balls into them, and then pass in argon protective gas for high-energy ball milling, in which the ball mill The rotating speed is 3000r / min, the mass ratio of balls and powder is 10:1, after ball milling for 20h, the ball milling mixed powder is obtained; Heat treatment at ℃ for 2 hours to obtain the first precursor;

[0063] (2) Proportioning the first precursor and the asphalt powder ...

Embodiment 2

[0071] A composite silicon negative electrode material prepared by the following method:

[0072] (1) Select silicon powder with a median particle size of 150-200nm as nano-silicon, place it in a rotary furnace with a rotating speed of 20r / min, and then feed a mixed gas of oxygen and argon with a volume ratio of 1:1, and the gas flow rate is 2L / min, heat treatment at 600°C for 1h, to obtain a heat-treated silicon powder;

[0073] Mix primary heat-treated silicon powder and titanium dioxide powder with a median particle size of 50nm at a mass ratio of 100:10 and put them into a rotary furnace, then feed ammonia and argon at a volume ratio of 1:1 at a gas flow rate of 1L / min. gas mixture, heat treatment at 900°C for 1 hour to obtain the first precursor;

[0074] (2) The first precursor is placed in a rotary furnace with a rotating speed of 10rpm / min, methane gas is introduced at a gas flow rate of 0.5L / min, and gas phase coating treatment is performed at 900°C to obtain the sec...

Embodiment 3

[0080] A composite silicon negative electrode material prepared by the following method:

[0081] (1) Put silicon powder with a median particle size of 1 to 30nm in a rotary furnace with a rotating speed of 30r / min, and then feed a mixed gas of neon gas and oxygen with a volume ratio of 1:0.1 at a gas flow rate of 0.8L / min , thermal oxidation treatment was carried out at 1200°C for 1 hour to obtain a heat-treated silicon powder;

[0082] Mix primary heat-treated silicon powder, aluminum powder and tin powder in a mass ratio of 100:5:5 and put them into a high-energy ball mill, and put 1mm zirconium balls into it, and then pass in argon protective gas for high-energy ball milling, wherein the ball mill speed 2000r / min, the mass ratio of balls and powder is 50:1, after ball milling for 30h, the ball milled mixed powder is obtained; then the ball milled mixed powder is placed in a rotary furnace with a rotating speed of 20r / min, and argon gas is introduced, and the temperature is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com