Preparation method and application of carbon tin nanometer composite powder

A nanocomposite powder, tin powder technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc. low rate and other problems, to achieve the effects of good cycle stability, low cost, and high reversible lithium storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Press 80g of tin micron powder into a bulk target material, place this in an automatically controlled DC arc hydrogen plasma device as an anode, and a carbon rod as a cathode, feed a mixed gas of methane and argon at a ratio of 1:0.5, and evaporate Fast body target material, through condensation, passivation and other process steps to obtain carbon-coated tin nanocomposite powder materials.

[0021] According to the mass ratio, the above-mentioned 80% carbon-tin nanocomposite powder, 10% carbon black and 10% polytetrafluoroethylene binder are uniformly mixed to make electrode sheets, and 1mol / L LiPF 6 The solution electrolyte, and metal lithium sheets were assembled into a button battery in a glove box. At a current density of 0.2mA / cm 2 And the voltage is tested within the range of 2 ~ 0.01V. The first reversible specific capacity of the carbon-tin nanocomposite powder was measured to be 560mAh / g.

Embodiment 2

[0023] The implementation steps are basically the same as in Example 1, except that the ratio of methane and argon in the mixed atmosphere is 1:1; the obtained carbon-coated tin nanocomposite powder is made into an electrode sheet and tested, and the first reversible ratio The capacity is 310mAh / g.

Embodiment 3

[0025] The implementation steps are basically the same as in Example 1, except that the ratio of methane and argon in the mixed atmosphere is 1:2; the obtained carbon-coated tin nanocomposite powder is made into an electrode sheet and tested, and the first reversible ratio The capacity is 620mAh / g.

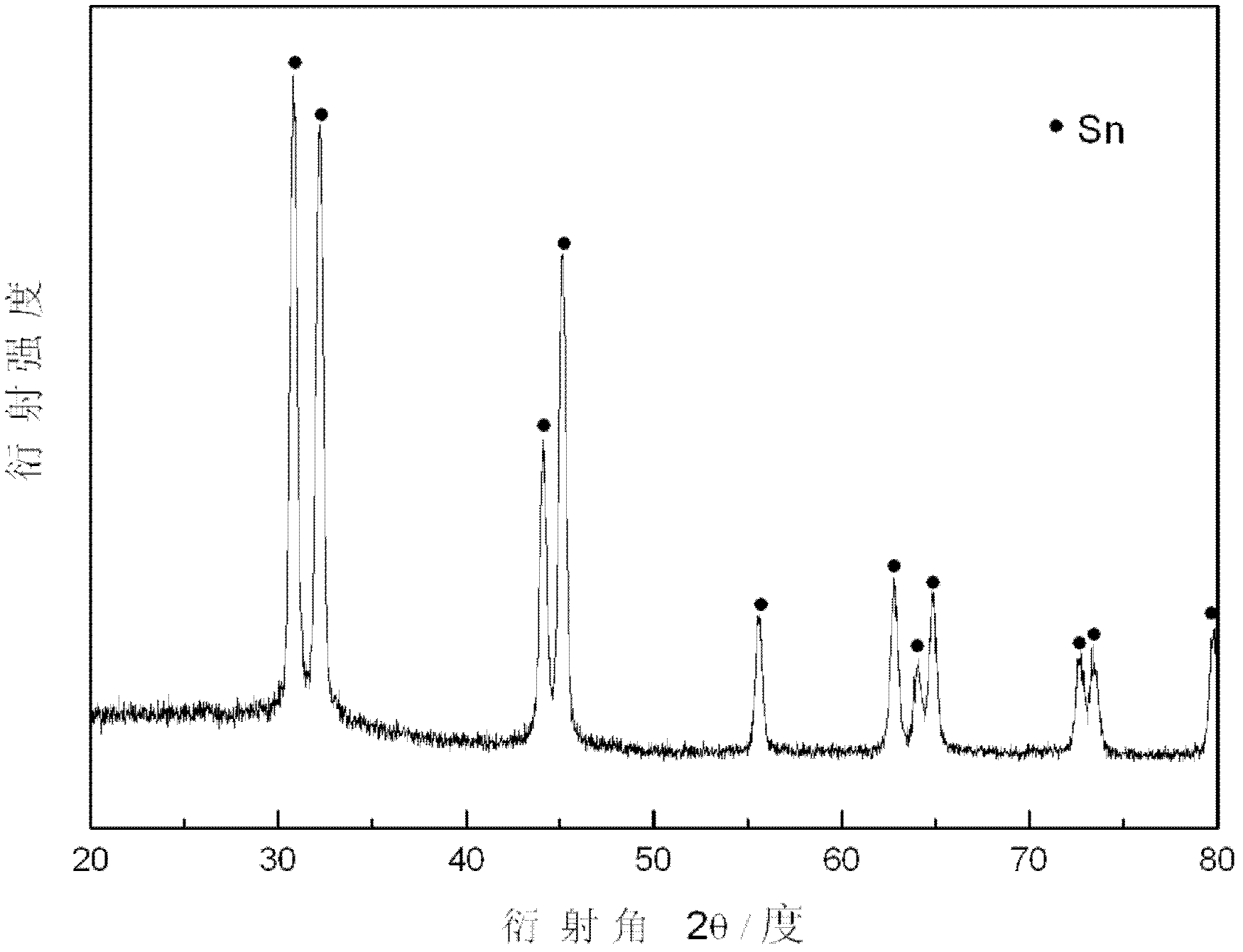

[0026] Embodiment three obtains the XRD pattern of carbon-coated tin nanocomposite powder figure 1 shown. The figure shows that the main phase of the composite is metallic tin.

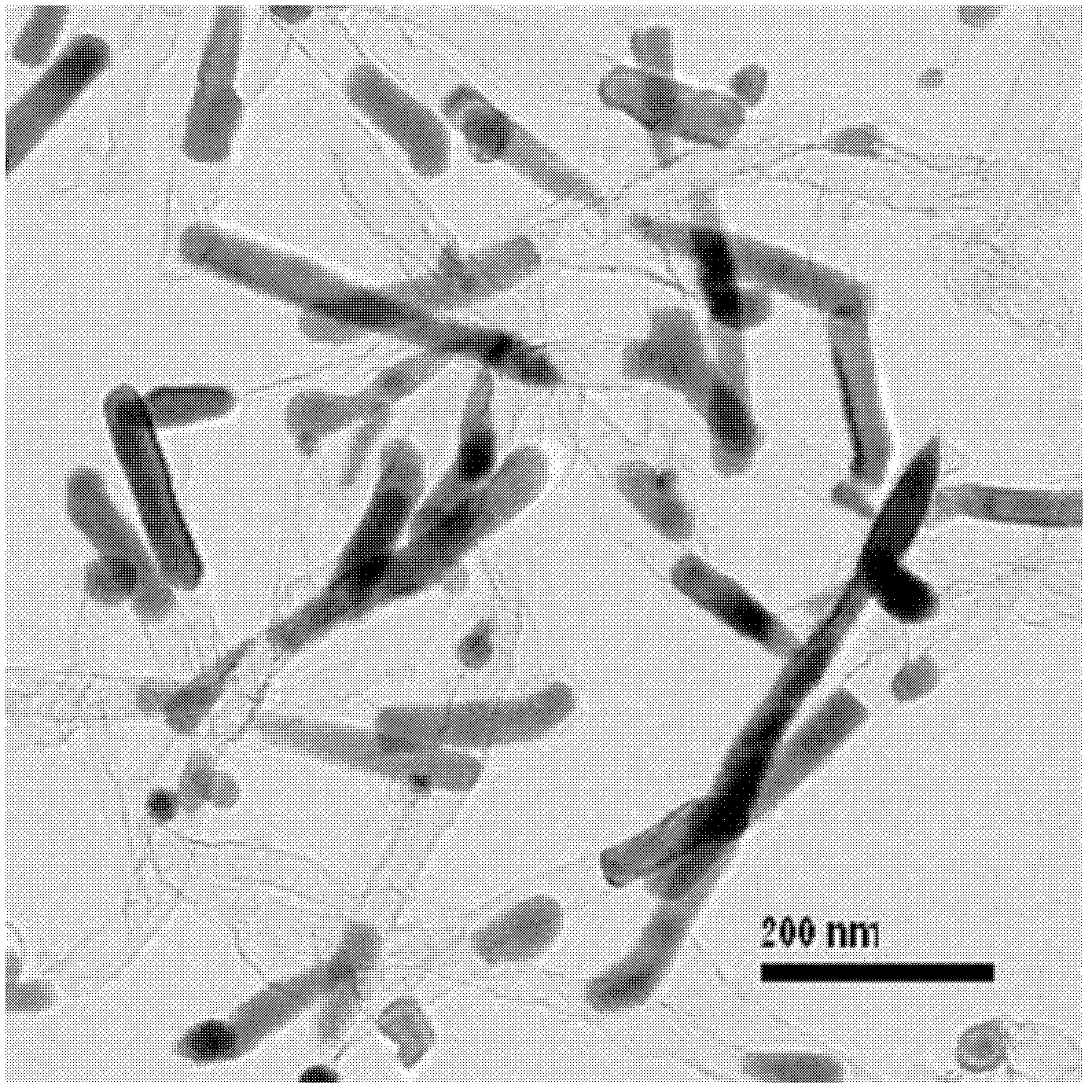

[0027] Example 3 Obtaining the TEM image of carbon-coated tin nanocomposite powder figure 2 shown. The figure shows the microstructure of the composite material as carbon nanotubes partially filled with metallic tin.

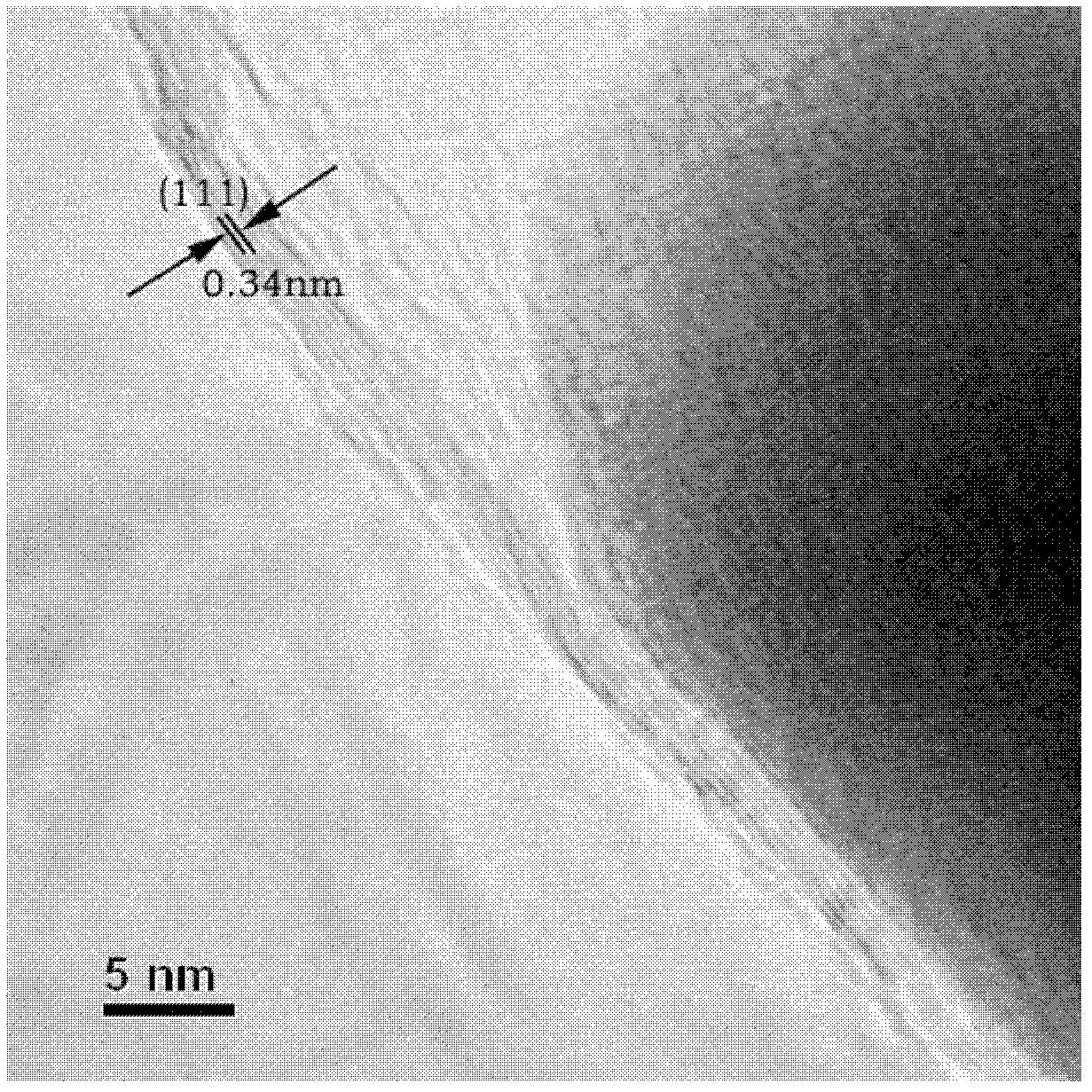

[0028] Example 3 Obtaining the TEM image of carbon-coated tin nanocomposite powder image 3 shown. The figure shows that the carbon nanotubes in the composite material are multi-walled carbon nanotubes.

[0029] Embodiment three obtains carbon-coated tin nano-composite powder, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com