Modified silicon monoxide material for lithium ion battery negative electrode and preparation method thereof

A silicon monoxide and lithium battery technology, applied in silicon oxide, electrode manufacturing, silicon dioxide, etc., can solve the problems of low initial coulombic efficiency, uneven dispersion, stability, poor cycle performance of lithium batteries, etc., to improve coulombic efficiency , Improving electrochemical performance and reducing the effect of the first irreversible capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

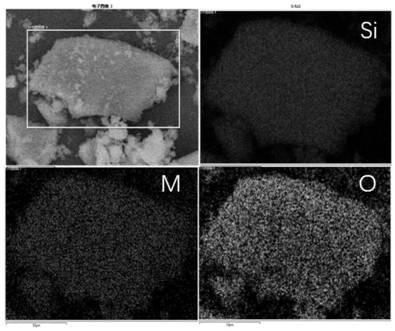

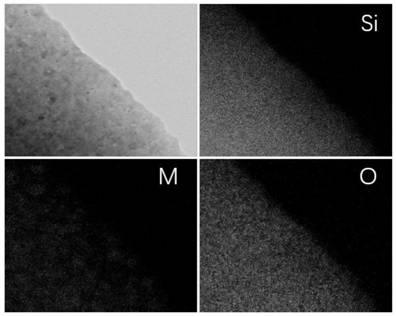

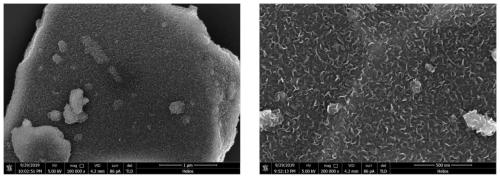

[0050] (1) Combine 8.225kg silicon powder, 8.625kg silicon dioxide and 5kg MgSiO 3 Powder, 2kg Li 2 Si 2 O 5 The powder and 95L of water were added to the ball mill and milled at 600r / min for 3h to obtain a slurry with a solid content of about 20%. Then the slurry was spray-dried to form raw material microspheres with uniformly distributed components. The raw material microspheres are compressed into a block using a hydraulic forming machine, and then dried in a vacuum oven at 60°C for 3 hours, and dried to obtain a raw material block;

[0051] (2) Load the compressed raw material block into the heating zone of the silicon monoxide preparation equipment, draw the vacuum to around 5Pa and start heating at a heating rate of 50°C per minute. After heating to 1300°C, keep it for 20 hours while maintaining the collection area The temperature is 500℃, and then it is cooled to room temperature, the deposited bulk material is taken out, and the jaw crusher crushes it to coarse particles o...

Embodiment 2

[0059] Other operations are the same as in Example 1, the difference is that the amount of raw materials is changed to 7.5kg silicon powder, 10.5kg silicon dioxide and 5kgMgSiO 3 Powder and 90L water.

Embodiment 3

[0061] Other operations are the same as in Example 1, the difference is that the amount of raw materials is changed to 4.9kg silicon powder, 7.5kg silicon dioxide and 2.5kg Li 2 Si 2 O 5 Powder and 60L water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com