Lithium-rich manganese material, positive electrode material for lithium-ion battery, positive plate for lithium-ion battery, lithium-ion battery and preparation method of lithium-ion battery

A lithium-ion battery and cathode material technology, which is applied in battery electrodes, electrolyte storage battery manufacturing, and positive electrodes, etc., can solve the problems of not being made into a full battery, low first coulombic efficiency, low coulombic efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

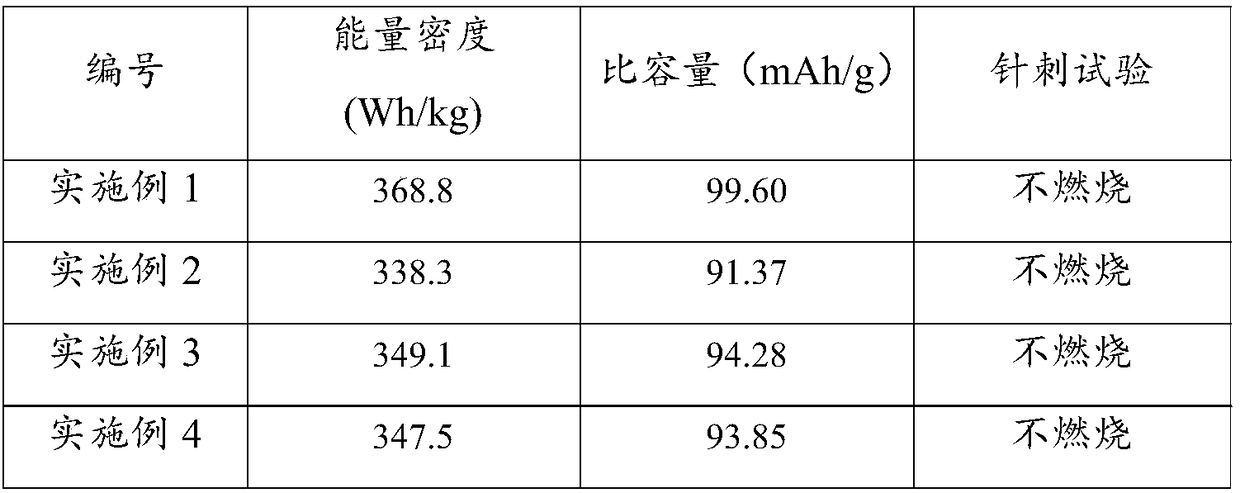

Embodiment 1

[0143] A lithium ion, the active material of the positive electrode material on the positive electrode sheet is a lithium-rich manganese material, and the molecular formula is 0.1Li 2 MnO 3 0.9LiNi 0.5 mn 1.5 o 4 0.9LiNi 0.5 mn 0.5 o 2 , D50 is 8.2μm, specific surface area is 0.37m 2 / g, the specific capacity is 245mAh / g. The active material of the negative electrode material on the negative electrode sheet is SiO / artificial graphite material, D50 is 9.5μm, and the specific surface area is 3.85m 2 / g, the specific capacity is 550mAh / g.

[0144] The preparation method of lithium ion battery comprises the following steps:

[0145] (1) Preparation of positive and negative electrodes:

[0146] According to the mass ratio of positive electrode material active material: acetylene black + Ks-6: polyvinylidene fluoride = 94: 1.5: 4.5 weighed, N-methylpyrrolidone as a solvent, add polyvinylidene fluoride, stir and mix evenly, then add acetylene black +Ks-6. Stir the active m...

Embodiment 2

[0153] A lithium-ion battery, wherein the active material of the positive electrode material is a lithium-rich manganese material, and the molecular formula is 0.05Li 2 MnO 3 0.95LiNi 0.5 mn 1.5 o 4 0.95LiNi 0.5 mn 0.5 o 2 Material, D50 is 6μm, specific surface area is 0.56m 2 / g, specific capacity is 235mAh / g, others are identical with embodiment 1.

Embodiment 3

[0155] A lithium-ion battery, wherein the active material of the positive electrode material is a lithium-rich manganese material with a molecular formula of 0.2Li 2 MnO 3 0.8LiNi 0.5 mn 1.5 o 4 0.8LiNi 0.5 mn 0.5 o 2 Material, D50 is 10μm, specific surface area is 0.32m 2 / g, specific capacity is 240mAh / g, others are identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com