Anode active material of lithium ion battery and preparation method thereof

A lithium-ion battery and anode activity technology, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of lack of space for anode active material particles, affecting the service life of lithium-ion batteries, and falling off of anode active materials. Chemical properties, slowing volume expansion, reducing the effect of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

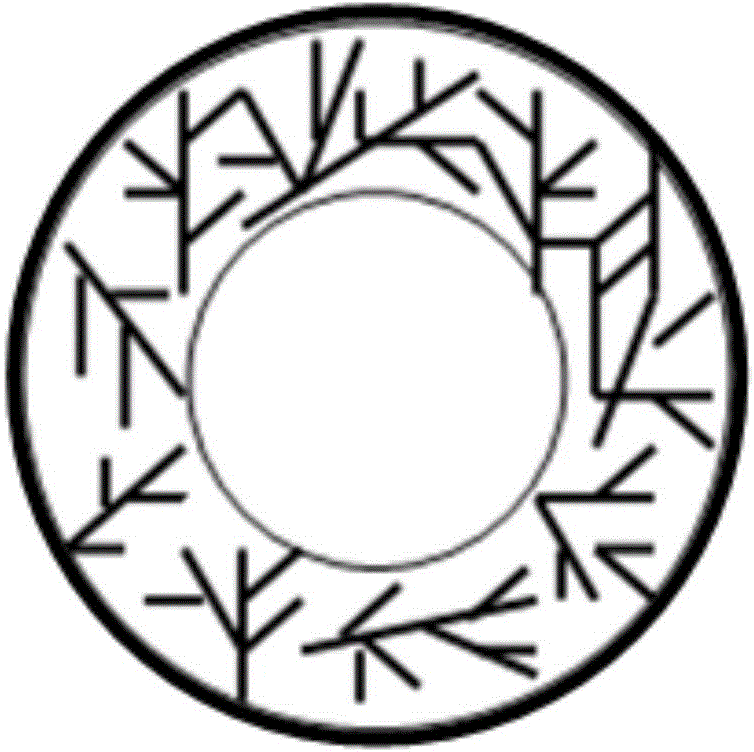

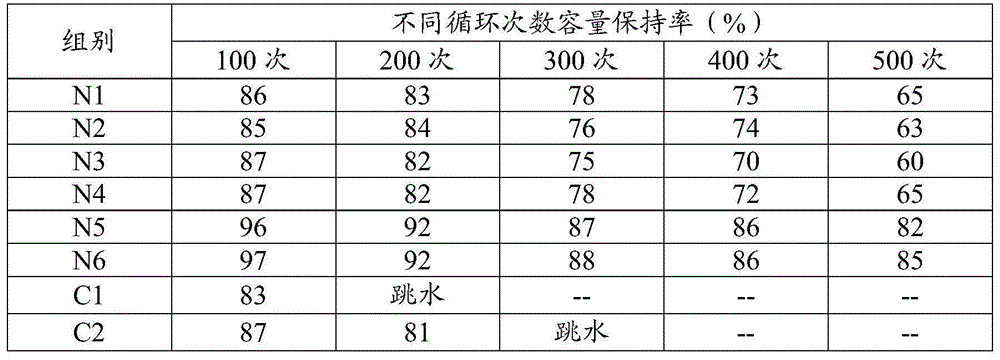

[0039] Si and Al are smelted with an electric arc in an inert atmosphere at a molar ratio of 10%: 90%. After 4 repeated smelting, the composition of the alloy is guaranteed to be uniform; 2 o 3 Covering, using an electromagnetic induction furnace to heat and melt, the degree of superheat is 300K; then, cool down and solidify, after 5 heating-cooling cycles, after the degree of supercooling reaches 200K, the supercooled Si-Al alloy melt is quickly blown with inert gas To achieve rapid solidification on a high-speed rotating copper roller with a line speed of 30m / s. Since the component Al belongs to a low-melting point metal, it is easy to gasify, and forms a gas nucleus under the interaction of internal and external gases, resulting in self-aeration. At the same time, the alloy melt is sprayed onto the high-speed rotating copper roller surface, which is strongly sheared by the roller surface. Force impact easily forms hollow Si-Al alloy particles. Under these conditions, the ...

Embodiment 2

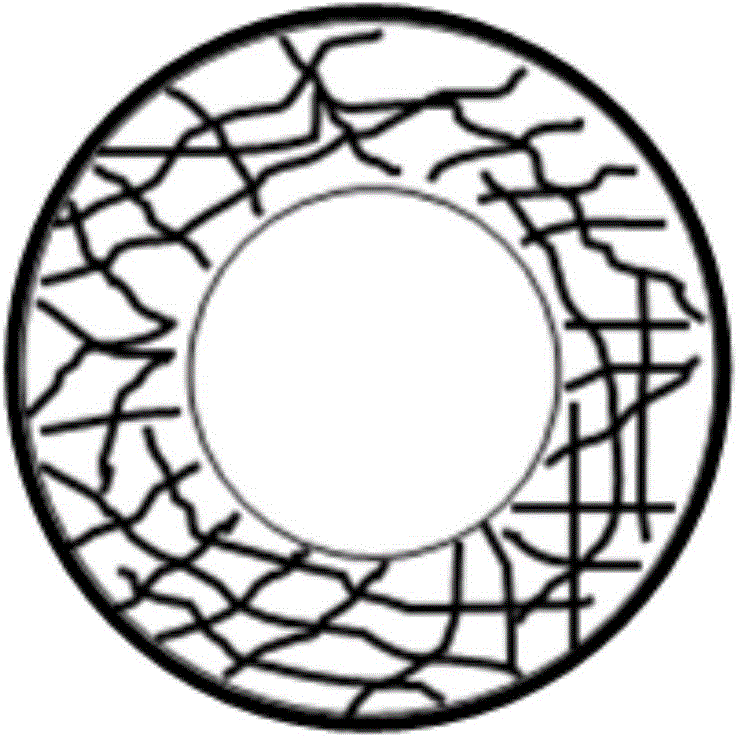

[0043] Si and Sn are smelted with an electric arc in an inert atmosphere at a molar ratio of 50%:50%, and the composition of the alloy is guaranteed to be uniform after 10 times of repeated smelting; the smelted Si-Sn alloy is purified with anhydrous glass (70%B 2 o 3 +20%Na 2 B 4 o 7 +10%Na 2 SiO 3 ) covering, using an electromagnetic induction furnace to heat and melt, and the degree of superheat is 200K; then, cool down and solidify, and after 6 heating-cooling cycles, after the degree of supercooling reaches 200K, the supercooled Si-Sn alloy melt is rapidly cooled by inert gas Blow onto a high-speed rotating copper roll with a line speed of 40m / s to achieve rapid solidification. Since the component Sn is a low-melting point metal, it is easy to gasify, and forms gas nuclei under the interaction of internal and external gases, resulting in self-aeration. At the same time, the alloy melt is sprayed onto the high-speed rotating copper roller surface, which is strongly sh...

Embodiment 3

[0047] Si, Al and Sn are smelted by electric arc in an inert atmosphere at a molar ratio of 40%: 30%: 30%. After 7 times of repeated smelting, the composition of the alloy is guaranteed to be uniform. The smelted Si-Al-Sn alloy is purified with anhydrous glass (70%B 2 o 3 +20%Na 2 B 4 o 7 +10%Al 2 o 3 ) cover, using an electromagnetic induction furnace to heat and melt, the degree of superheat is 300K; then, cool down and solidify, after 4 heating-cooling cycles, after the degree of supercooling reaches 100K, use an inert gas to melt the supercooled Si-Al-Sn alloy The body is quickly blown onto a high-speed rotating copper roller at a line speed of 45m / s to achieve rapid solidification. Since the components Al and Sn are both low-melting point metals, they are easy to gasify and form gas nuclei under the interaction of internal and external gases, resulting in self-aeration. At the same time, the alloy melt is sprayed onto the high-speed rotating copper roller surface, w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com