Method for preparing polyacrylonitrile carbon fiber with gamma ray irradiation

A technology of polyacrylonitrile carbon fiber and polyacrylonitrile fiber, which is applied in the field of preparation of polyacrylonitrile carbon fiber, can solve problems affecting the mechanical properties of carbon fiber, achieve the effects of shortening stabilization time, high rigidity drafting, and improving orientation degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

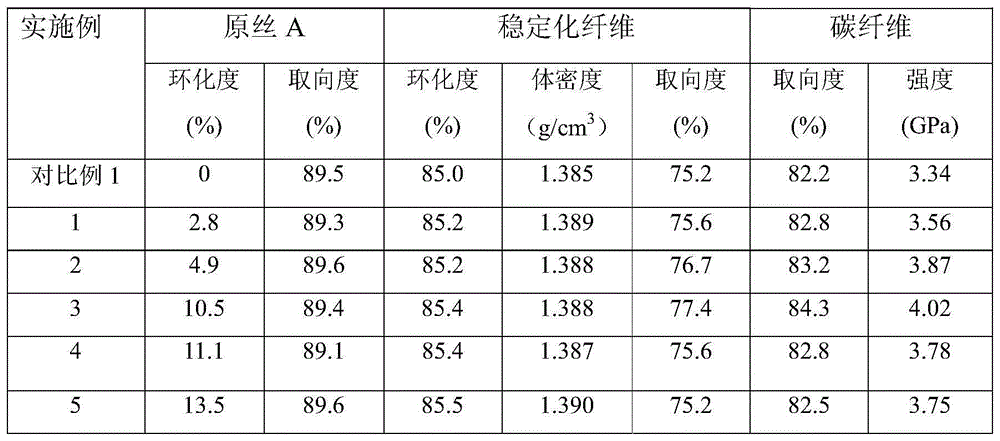

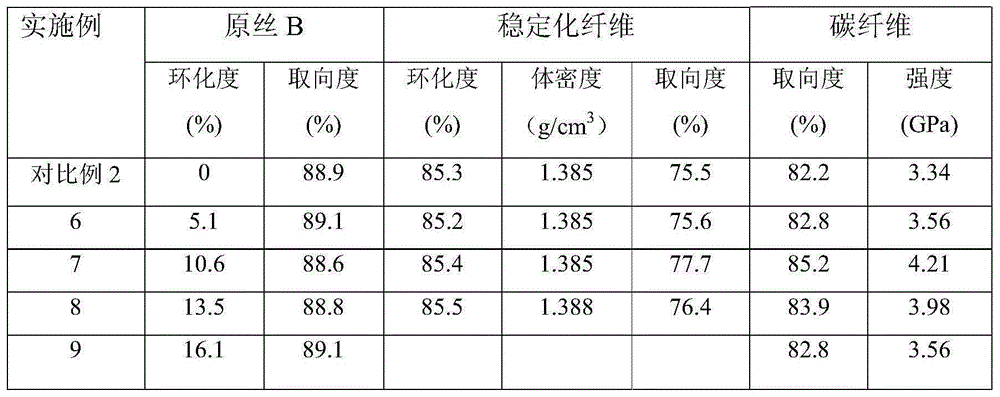

Embodiment 1

[0022] Select 3K (that is, 3000 single filaments / bundle) polyacrylonitrile precursors containing acrylamide copolymers (denoted as: precursor A), first carry out in the air atmosphere 60 Coγ-ray irradiation, irradiation dose rate 1kGy / h, irradiation time 50h, the total irradiation dose is 50kGy, to obtain radiation modified "cold cross-linked" polyacrylonitrile fiber. Then, the irradiated polyacrylonitrile fibers were subjected to thermal stabilization treatment in five temperature ranges of 200°C, 220°C, 235°C, 250°C and 280°C in air medium, and the residence time in each temperature zone was 15min. A total of 75 minutes. The tension control is as follows: the tension control in the first and second temperature zones is 30MPa, the tension control in the third temperature zone is 24MPa, and the tension control in the third temperature zone is 30MPa. That is, heat-stabilized fibers are obtained. Under the protection of nitrogen, the thermally stabilized fiber is subjected to ...

Embodiment 2

[0026] Fiber sample is the same as embodiment 1, at first carries out in air atmosphere 60 Co gamma ray irradiation, the irradiation dose rate is 1kGy / h, the irradiation time is 100h, and the total irradiation dose is 100kGy to obtain radiation-modified "cold cross-linked" polyacrylonitrile fibers. Then, the irradiated polyacrylonitrile fibers were subjected to heat stabilization treatment in five temperature ranges of 200°C, 220°C, 235°C, 250°C and 280°C in air medium, and the residence time in each temperature zone was 12.5min. , a total of 60 minutes. The tension control is as follows: the tension control in the first and second temperature zones is 35MPa, the tension control in the third temperature zone is 26MPa, and the tension control in the third temperature zone is 35MPa. That is, heat-stabilized fibers are obtained. Under the protection of nitrogen, the thermally stabilized fiber was carbonized at 400°C, 450°C, 600°C and 850°C at a temperature of 12.5 minutes, and ...

Embodiment 3

[0028] Fiber sample is the same as embodiment 1, at first carries out in air atmosphere 60 Coγ-ray irradiation, the irradiation dose rate is 2kGy / h, the irradiation time is 100h, and the total irradiation dose is 200kGy to obtain radiation-modified "cold cross-linked" polyacrylonitrile fibers. Then, the radiation-modified polyacrylonitrile fibers were subjected to thermal stabilization treatment in five temperature ranges of 200°C, 220°C, 235°C, 250°C and 280°C in air medium, and the residence time in each temperature zone was 11min. A total of 55 minutes. The tension control is as follows: the tension control in the first and second temperature zones is 37.5MPa, the tension control in the third temperature zone is 28MPa, and the tension control in the third temperature zone is 37.5MPa. That is, heat-stabilized fibers are obtained. Under the protection of nitrogen, the thermally stabilized fiber was carbonized at a low temperature of 400°C, 450°C, 600°C and 850°C. The reside...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com