Nano-zinc oxide composite triazophos pesticide and preparation method therefor

A technology of nano-zinc oxide and compound triazophos, applied in the field of pesticides, can solve the problems of low degradation efficiency, high toxicity of triazophos pesticide residues and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

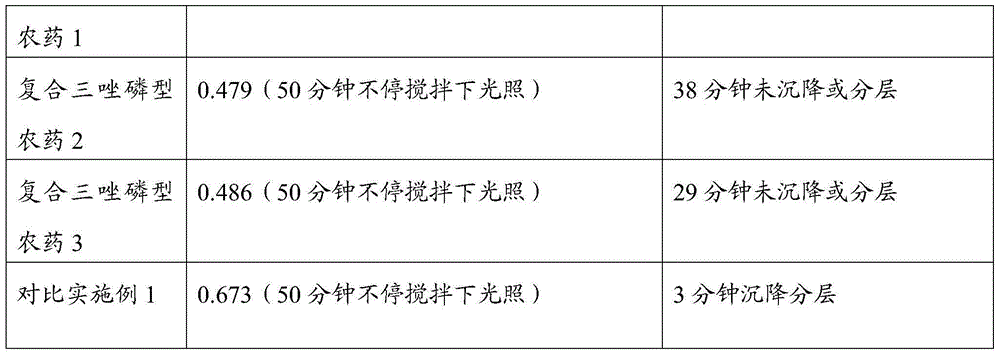

Embodiment 1

[0018] (1) 1kg of urea is added to the zinc nitrate solution of 5kg of 0.1mol / L, and in a water bath, under 98 ℃ of reaction temperatures, the reaction is obtained for 0.5h to obtain a precipitate;

[0019] (2) The precipitate was collected by centrifugation, washed once with deionized water, and then washed with absolute ethanol for 5 times to obtain a zinc oxide precursor. The iron oxide precursor was dried at a temperature of 60 ° C for 8 hours, and then dried at 410 ° C. Calcined at the temperature for 4h to obtain nano-zinc oxide powder 1.

Embodiment 2

[0021] (1) 1kg urea is added in the zinc nitrate solution of 2kg 3mol / L, in a water bath, under 62 ℃ of reaction temperatures, the reaction 3h obtains a precipitate;

[0022] (2) The precipitate was collected by centrifugation, washed with deionized water for 5 times, and then washed with absolute ethanol once to obtain a zinc oxide precursor. The iron oxide precursor was dried at 180 ° C for 1 hour, and then placed After calcination at 820°C for 2 hours, nano-zinc oxide powder 2 was obtained.

Embodiment 3

[0024] (1) 1kg urea is added to the zinc nitrate solution of 3kg 1mol / L, and in a water bath, under 80 ℃ of reaction temperatures, react 2h to obtain a precipitate;

[0025] (2) The precipitate is collected by centrifugation, washed with deionized water for 3 times, and then washed with absolute ethanol for 3 times to obtain a zinc oxide precursor, and the iron oxide precursor is dried at a temperature of 100 ° C for 5 hours. After calcination at 620°C for 3 hours, nano-zinc oxide powder 3 was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com