High-oxidization-resistance and high-conductivity crosslinked type polybenzimidazole high-temperature proton exchange membrane and preparation method therefor

A technology of proton exchange membrane and polybenzimidazole, which is applied in fuel cell components, circuits, fuel cells, etc., can solve the problems of aggravated PBI membrane degradation and battery performance degradation, and achieve excellent dimensional stability and high oxidation resistance Performance, the effect of solving the loss of phosphoric acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

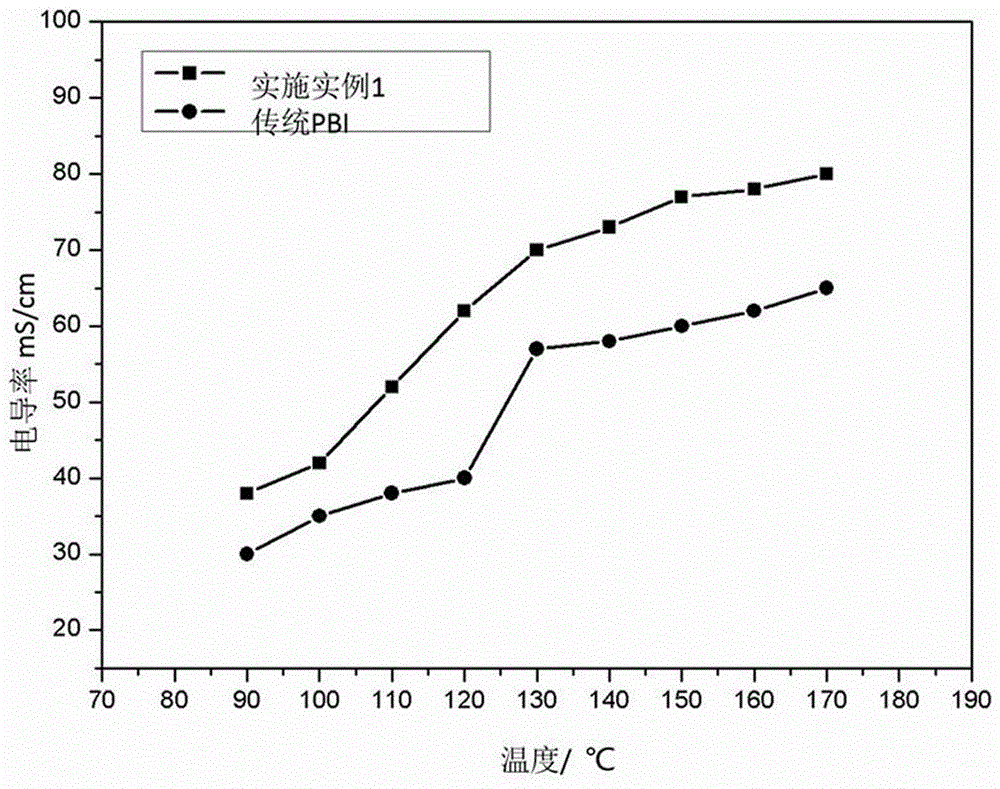

Embodiment 1

[0029] A method for preparing a cross-linked polybenzimidazole high-temperature proton exchange membrane with high oxidation resistance and high conductivity, comprising the following steps:

[0030] (1) Dissolve 2 g of 1-vinyl-1,2,4-triazole in 20 mL of N-methylpyrrolidone, and then add the chain initiator azobisisobutyronitrile, wherein the mass content of the chain initiator is 25% of the high boiling point solvent; put it in an oil bath, react for 48 h, and the reaction temperature is 50 °C;

[0031] (2) Add 1 g polybenzimidazole to the solution, stir to dissolve, then add vinylphosphonic acid, stir to dissolve, add azobisisobutyronitrile, stir at room temperature for 2 h, nitrogen protection, gas flow rate is 100 mL / min;

[0032] (3) Put the solution in an oil bath, stir at 100 °C, and react for 48 h;

[0033] (4) Continue to add 10 mL of N-methylpyrrolidone to the solution, stir for 30 min, add manganese dioxide as a free radical quencher, stir ultrasonically for 30 m...

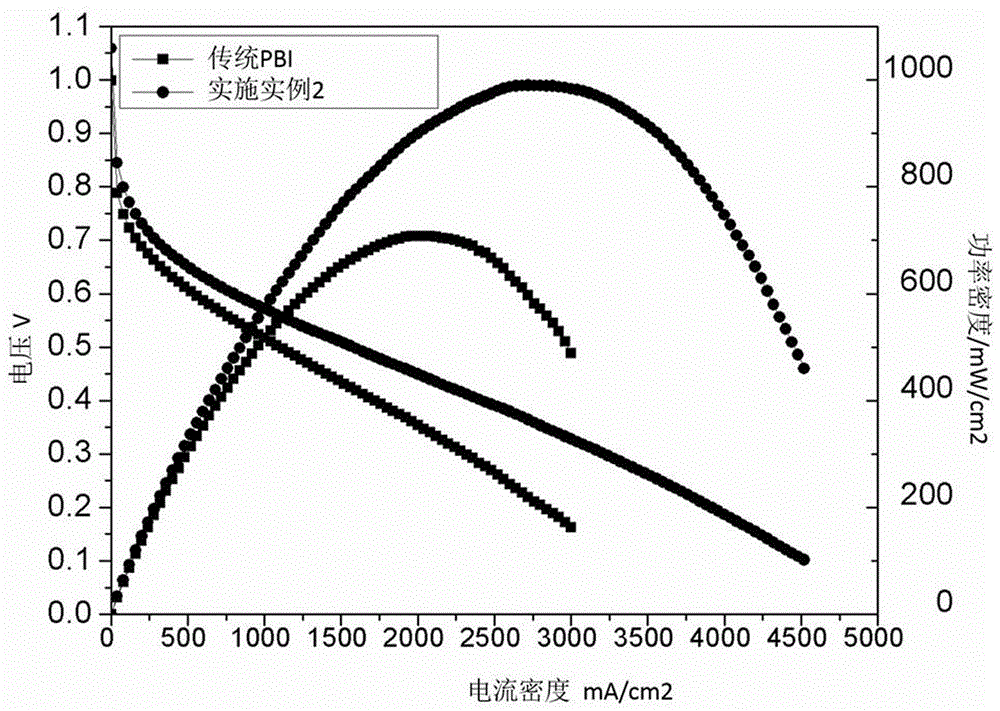

Embodiment 2

[0039] A method for preparing a cross-linked polybenzimidazole high-temperature proton exchange membrane with high oxidation resistance and high conductivity, comprising the following steps:

[0040] (1) Dissolve 1.5 g of 1-vinyl-1,2,4-triazole in 15 mL of N-methylpyrrolidone solvent, then add the chain initiator azobisisobutyronitrile, the mass content of the chain initiator 38% of the high boiling point solvent, placed in an oil bath, reacted for 28 h, and the reaction temperature was 80 °C;

[0041] (2) Add 0.8 g polybenzimidazole to the solution, stir to dissolve, then add vinylphosphonic acid, stir to dissolve, add azobisisobutyronitrile, stir at room temperature for 2 h, nitrogen protection, gas flow rate is 100 mL / min;

[0042] (3) Put the solution in an oil bath, stir at 50 °C, and react for 48 h;

[0043] (4) Continue to add 8 mL of N-methylpyrrolidone solvent to the solution, stir for 30 min, add the free radical quencher ceria, stir ultrasonically for 30 min, pou...

Embodiment 3

[0049] A method for preparing a cross-linked polybenzimidazole high-temperature proton exchange membrane with high oxidation resistance and high conductivity, comprising the following steps:

[0050] (1) Dissolve 0.8 g of 1-vinyl-1,2,4-triazole in 10 mL of N-methylpyrrolidone solvent, then add the chain initiator azobisisobutyronitrile, the mass content of the chain initiator 30% of the high boiling point solvent, placed in an oil bath, reacted for 36 h, and the reaction temperature was 70 °C;

[0051] (2) Add 0.5 g polybenzimidazole to the solution, stir to dissolve, then add vinylphosphonic acid, stir to dissolve, add azobisisobutyronitrile, stir at room temperature for 1.5 h, protect with nitrogen, and the gas flow rate is 100 mL / min;

[0052] (3) Put the solution in an oil bath, stir at 80 °C, and react for 24 h;

[0053] (4) Continue to add 5 mL of N-methylpyrrolidone solvent to the solution, stir for 30 min, add the free radical quencher ceria, stir ultrasonically for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com