Supramolecular multi-copolymer type clean fracturing fluid

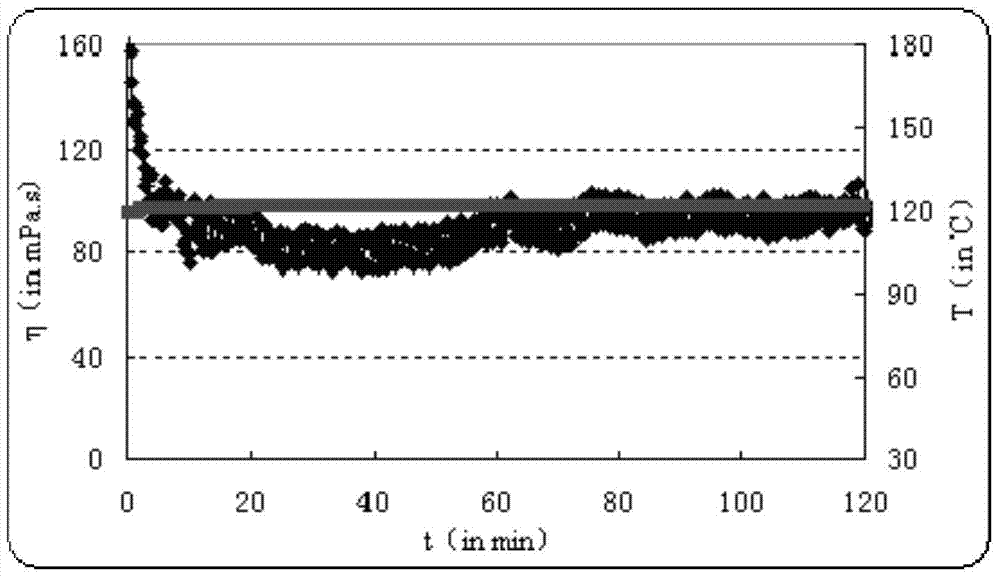

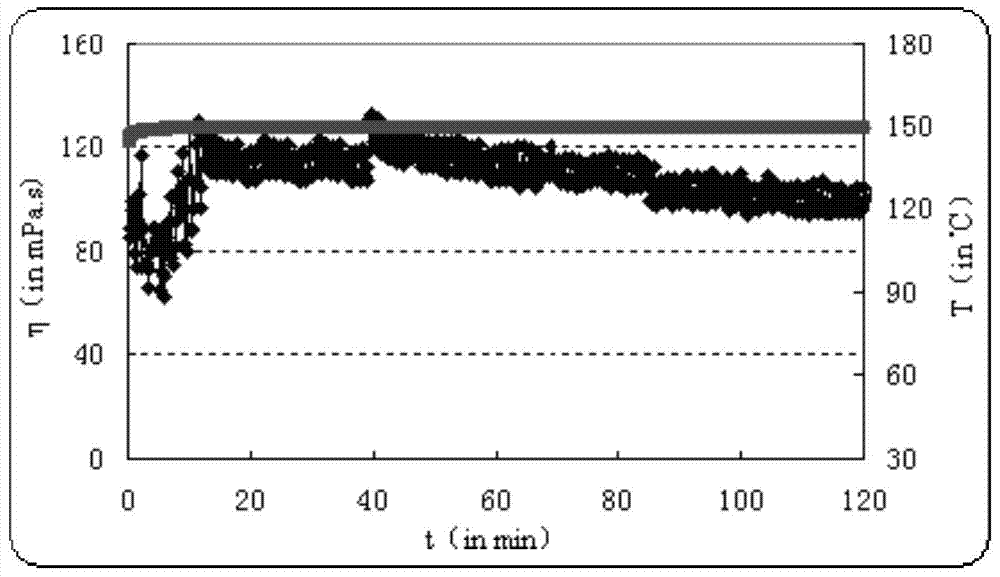

A multi-copolymer, clean fracturing fluid technology, applied in the field of oil field fracturing, can solve the problems of fracturing effect, high cost, poor stability, etc. Rheological curve without protrusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

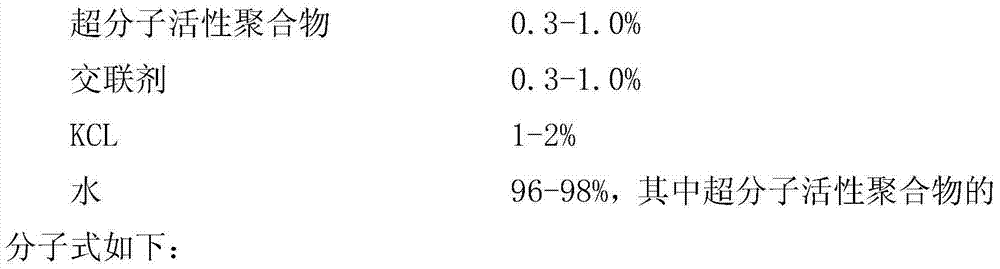

[0035] A supramolecular multi-polymer copolymer type clean fracturing fluid is composed of the following components according to the corresponding mass percentages:

[0036]

[0037] Wherein, the molecular formula of supramolecular active polymer is as follows:

[0038]

[0039] In the formula, R is a C13-C21 linear or branched alkyl group, n is an integer of 3-6, and p is an integer of 2-4.

[0040] Supramolecular active polymer is obtained by the following steps in the present embodiment:

[0041] 1) Accurately weigh 30 grams of acrylamide, 5 grams of N-vinylpyrrolidone, 1 gram of cetyl acrylate, 2 grams of 2-acrylamide-2-methylpropanesulfonic acid (AMPS) and 0.5 grams of dodecyl Sodium benzenesulfonate was added to 200 grams of distilled water, and dissolved for later use;

[0042] 2) Accurately weigh 0.1 g of ammonium persulfate, add 25 g of distilled water, and dissolve for later use;

[0043] 3) Add the solution prepared in step 1) into a three-necked flask, put...

Embodiment 2

[0056] A supramolecular multi-polymer copolymer type clean fracturing fluid is composed of the following components according to the corresponding mass percentages:

[0057]

[0058] Wherein, the molecular formula of supramolecular active polymer is as follows:

[0059]

[0060] In the formula, R is a C13-C21 linear or branched alkyl group, n is an integer of 3-6, and p is an integer of 2-4.

[0061] Supramolecular active polymer is obtained by the following steps in the present embodiment:

[0062] 1) Accurately weigh 45 grams of acrylamide, 10 grams of N-vinylpyrrolidone, 2 grams of cetyl acrylate, 3 grams of 2-acrylamide-2-methylpropanesulfonic acid (AMPS) and 1 gram of dodecyl Sodium benzenesulfonate was added to 200 grams of distilled water, and dissolved for later use;

[0063] 2) Accurately weigh 0.2 g of ammonium persulfate, add it into 25 g of distilled water, and dissolve it for later use;

[0064] 3) Add the solution prepared in step 1) into a three-necked ...

Embodiment 3

[0076] A supramolecular multi-polymer copolymer type clean fracturing fluid is composed of the following components according to the corresponding mass percentages:

[0077]

[0078] Wherein, the molecular formula of supramolecular active polymer is as follows:

[0079]

[0080] In the formula, R is a C13-C21 linear or branched alkyl group, n is an integer of 3-6, and p is an integer of 2-4.

[0081] Supramolecular active polymer is obtained by the following steps in the present embodiment:

[0082] 1) Accurately weigh 40 grams of acrylamide, 8 grams of N-vinylpyrrolidone, 2 grams of cetyl acrylate, 3 grams of 2-acrylamide-2-methylpropanesulfonic acid (AMPS) and 1 gram of dodecyl Sodium benzenesulfonate was added to 200 grams of distilled water, and dissolved for later use;

[0083] 2) Accurately weigh 0.2 g of ammonium persulfate, add it into 25 g of distilled water, and dissolve it for later use;

[0084] 3) Add the solution prepared in step 1) into a three-necked f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com