Plugging agent for drilling fluid and protecting low percolation reservoir

A plugging agent and drilling fluid technology, which is applied in drilling compositions, chemical instruments and methods, etc., can solve the problems of difficult particle size of plugging agents, lack of research on low-permeability reservoirs, and inability to form internal mud cakes. , to achieve the effect of low price, good blocking effect and shallow damage depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Take 30 parts of acid-soluble fiber, 5 parts of oil-soluble resin, 40 parts of acid-soluble deformable particles, 10 parts of high-temperature-resistant natural small molecule materials, 15 parts of calcium carbonate, and then add 15 parts of water, in a mixer at a temperature of 80 ° C After 30 minutes of compound reaction, it is dried, packaged and made into a low-permeability reservoir plugging agent for drilling fluid with a specific ratio.

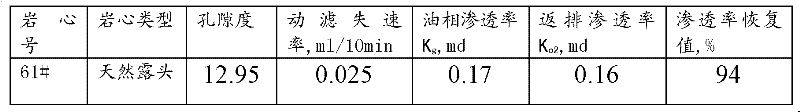

[0023] The products formed by this process are suitable for 0.1~1×10-3μm 2 Reservoir core plugging flowback:

[0024]

[0025] In the present invention, the acid-soluble fiber adopts kapok staple fiber and its modified products, the oil-soluble resin adopts polyvinyl alcohol oil-soluble resin, and the acid-soluble deformable particles adopt AMPS / AM / DMAM copolymer, which is a high-temperature-resistant natural small molecule The material is humic acid modified material.

Embodiment 2

[0027] Take 20 parts of acid-soluble fiber, 10 parts of oil-soluble resin, 50 parts of acid-soluble deformable particles, 5 parts of high-temperature-resistant natural small molecule materials, 10 parts of calcium carbonate, and then add 25 parts of water. After compounding for 60 minutes, it is dried, packaged and made into a low-permeability reservoir plugging agent for drilling fluid with a specific ratio.

[0028] Wherein, the material that each component adopts is the same as embodiment 1.

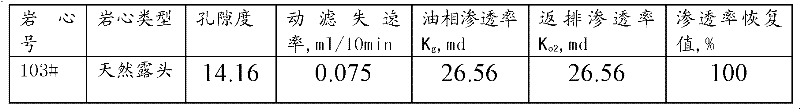

[0029] The products formed by this process are suitable for 10~50×10-3μm 2 Reservoir core plugging flowback:

[0030]

Embodiment 3

[0032] Take 10 parts of acid-soluble fiber, 10 parts of oil-soluble resin, 60 parts of acid-soluble deformable particles, 5 parts of high-temperature-resistant natural small molecule materials, 10 parts of calcium carbonate, and then add 20 parts of water. After compounding for 40 minutes, it is dried, packaged and made into a low-permeability reservoir plugging agent for drilling fluid with a specific ratio.

[0033] Wherein, the material that each component adopts is the same as embodiment 1.

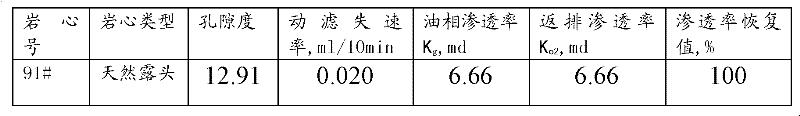

[0034] The products formed by this process are suitable for 1~10×10-3μm 2 Reservoir core plugging flowback:

[0035]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com