Asphalt layer leakage plugging slurry

A technology of plugging slurry and asphalt layer, applied in the field of drilling plugging agent, can solve the problems such as the lack of mutual solubility between the plugging slurry and the asphalt layer, the asphalt pollution of the plugging slurry, the weakening of the cementing ability and the pressure bearing capacity, etc. No curing treatment, high leak plugging success rate and strong anti-pollution ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

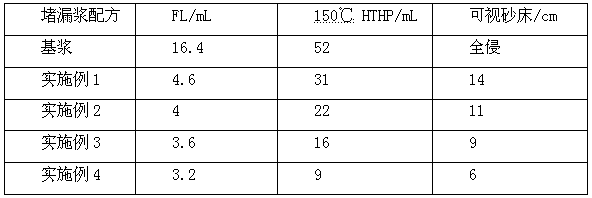

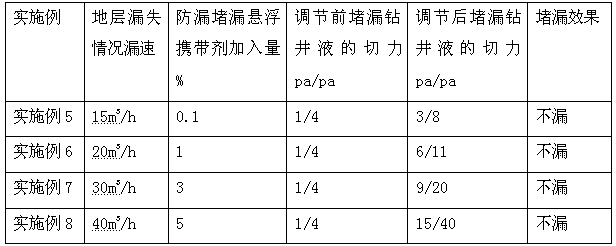

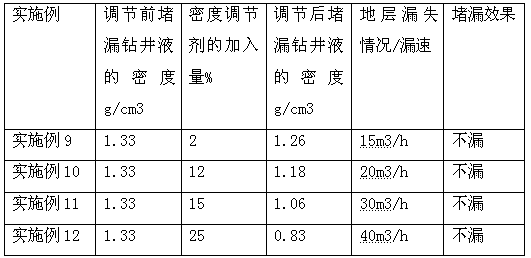

Examples

Embodiment 1

[0035] The anti-leakage plugging filler takes the following raw materials in parts by weight: 6 parts of aluminum hydroxide, 8 parts of silicon micropowder for ceramics, 10 parts of talcum powder, 4 parts of sodium silicate, 10 parts of nano calcium carbonate, ultrafine calcium carbonate ( 800-1200 mesh) 2 parts, bluestone powder (200-400 mesh) 4 parts, graphite 2 parts, white asphalt 2 parts, calcium oxide 3 parts.

[0036] Under normal temperature and pressure, add the above raw materials into the container in sequence according to the proportion, mix and stir evenly, wait for it to dry, crush or sieve into granular products with a particle size of 0.05mm~0.8mm by a twin-screw forced-pressure granulator.

[0037] When in use, add the anti-leakage and plugging filler of the present invention that accounts for 2% of the total amount of the plugging drilling fluid in the plugging drilling fluid. That is to say, the amount added is 2 tons of anti-leakage plugging filler per 100 ...

Embodiment 2

[0039] Weigh the following raw materials in parts by weight: 9 parts of aluminum hydroxide, 12 parts of silicon micropowder for ceramics, 15 parts of talc powder, 6 parts of sodium silicate, 13 parts of nano-calcium carbonate, 6 parts of ultra-fine calcium carbonate (800-1200 mesh) , 8 parts of bluestone powder (200-400 mesh), 4 parts of graphite, 5 parts of white asphalt, and 5 parts of calcium oxide.

[0040] Under normal temperature and pressure, add the above raw materials into the container in sequence according to the proportion, mix and stir evenly, wait for it to dry, crush or sieve into granular products with a particle size of 0.05mm~0.8mm by a twin-screw forced-pressure granulator.

[0041] When in use, add the anti-leakage and plugging filling agent of the present invention that accounts for 6% of the total amount of the plugging drilling fluid in the plugging drilling fluid.

Embodiment 3

[0043] Weigh the following raw materials in parts by weight: 12 parts of aluminum hydroxide, 16 parts of silicon micropowder for ceramics, 20 parts of talc powder, 8 parts of sodium silicate, 17 parts of nano-calcium carbonate, 8 parts of ultra-fine calcium carbonate (800-1200 mesh) , bluestone powder (200-400 mesh) 15 parts, graphite 6 parts, white asphalt 8 parts, calcium oxide 8 parts.

[0044] Under normal temperature and pressure, add the above raw materials into the container in sequence according to the proportion, mix and stir evenly, wait for it to dry, crush or sieve into granular products with a particle size of 0.05mm~0.8mm by a twin-screw forced-pressure granulator.

[0045] When in use, add the anti-leakage and plugging filler of the present invention that accounts for 12% of the total amount of the plugging drilling fluid in the plugging drilling fluid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com