Emulsion leaking stopping agent and preparing method thereof

A plugging agent and emulsion technology, which is applied in the field of emulsion plugging agent and its preparation, can solve the problems of difficult plugging agent, single plugging material and method, and repeated leakage, so as to increase the success rate of plugging and improve retention effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

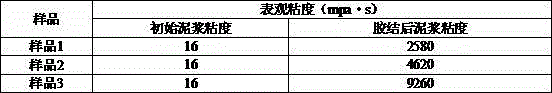

Examples

Embodiment 1

[0021] Add 12.50g of acrylamide as the first monomer, 10.00g of acryloyloxyethyl dimethyl benzyl ammonium chloride as the second monomer, 2.25g of butyl acrylate as the third monomer, and 2.25g of butyl acrylate as the fourth monomer 0.25g of N,N-methylenebisacrylamide and 200.00g of distilled water, mechanically stirred to form a turbid liquid; add 400.00g of synthetic base oil to the turbid liquid, and continue to add 1.00g of tetramethylammonium bromide , 0.75g of nonylphenol polyoxyethylene ether; cooling to 2°C in an ice-water bath, adding 0.0013g of sodium persulfate and 0.0013g of sodium bisulfite; passing inert gas nitrogen into the aqueous solution and keeping it for 60 minutes; under nitrogen atmosphere, Raise the temperature to 10° C., stir and react for 10 hours to obtain an emulsion sample.

Embodiment 2

[0023] Add 95.0g of acrylamide as the first monomer, 1.00g of methacryloxyethyltrimethylammonium chloride as the second monomer, 2.00g of vinyl acetate as the third monomer, and 2.00g of vinyl acetate as the fourth monomer in a 1000mL four-necked bottle. 0.010g of N,N-methylenebisacrylamide and 150.00g of distilled water, mechanically stirred to form a turbid liquid; add 300.00g of synthetic base oil to the turbid liquid, and continue to add 3.92g of tetramethylammonium bromide , 2.94g of nonylphenol polyoxyethylene ether; cooling to 2°C in an ice-water bath, adding 0.025g of sodium persulfate and 0.025g of sodium bisulfite; passing inert gas nitrogen into the aqueous solution and keeping it for 60 minutes; under nitrogen atmosphere, Raise the temperature to 30° C., stir and react for 10 hours to obtain an emulsion sample.

Embodiment 3

[0025] In a 1000mL four-necked bottle, add 50.00g of sodium acrylate to the first monomer, 29.80g of methacryloyloxyethyl dimethyl benzyl ammonium chloride to the second monomer, and 20.00g of hydroxypropyl methacrylate to the third monomer , the fourth monomer diacetone acrylamide 0.20g and distilled water 300.00g, and continue to add tetramethylammonium bromide 4.00g, nonylphenol polyoxyethylene ether 3.00g; ice-water bath cooling to 2 ° C, add persulfuric acid Sodium 0.016g, sodium bisulfite 0.016g; inert gas nitrogen was passed into the aqueous solution and kept for 60 minutes; under nitrogen atmosphere, the temperature was raised to 80°C, and the emulsion sample was obtained after stirring and reacting for 8 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com