Coating plugging agent, preparation method thereof, and plugging slurry

A leak-stopping agent and coating technology, which is applied in the field of coating a leak-stopping agent and its preparation method and leak-stopping slurry, can solve the problems of poor temperature resistance, single material, low leak-stopping pressure-bearing capacity, etc., and can improve the pressure-bearing capacity The effect of improving the density, improving the stability,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

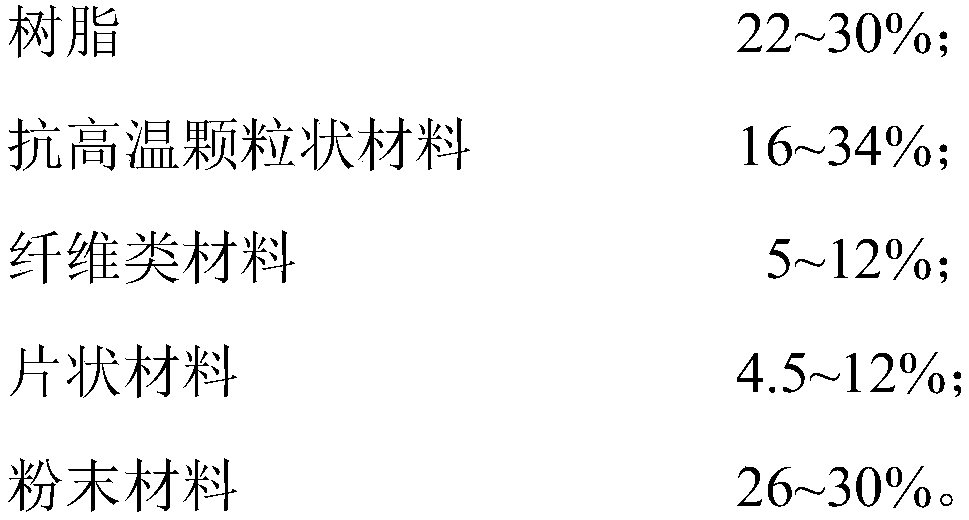

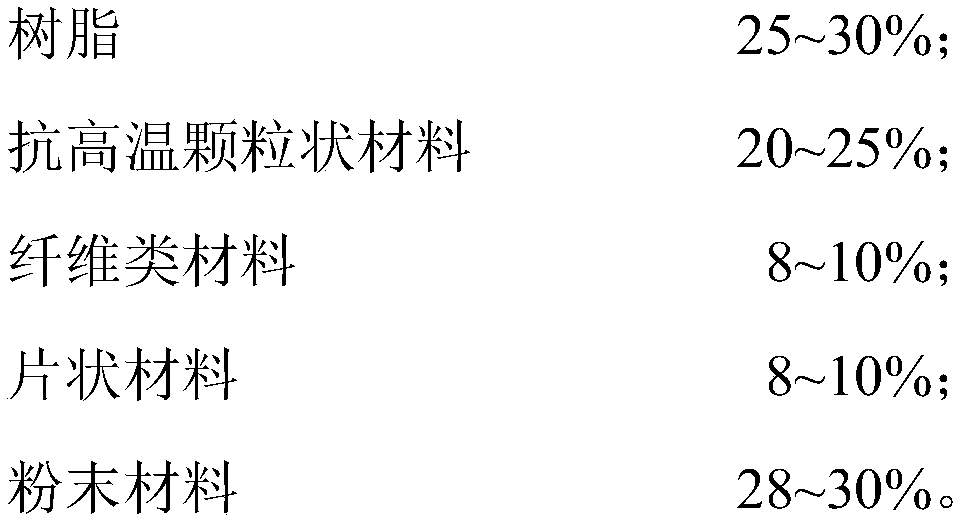

Method used

Image

Examples

Embodiment 1

[0030] Component dosage:

[0031] ABS resin: 3 parts by weight

[0032] Calcium carbonate particles (0.5 ~ 1mm): 2 parts by weight

[0033] Sepiolite fiber (0.5-1mm): 1 part by weight

[0034] Mica (0.1-0.5mm): 1 part by weight

[0035] Calcium carbonate powder (300-400 mesh): 3 parts by weight

[0036] Heat the ABS resin to a molten state, add other plugging materials, mix evenly, cool to room temperature, and use a pulverizer to crush into small pieces with a particle size of 1-2 mm to obtain a coated plugging agent. Add 10 parts by weight of the coated plugging agent to 100 parts by weight of the bentonite slurry to prepare the plugging slurry, prepare 2000 mL of the plugging slurry according to the above formula, and set aside.

[0037]Install a 1mm simulated fracture core in the DL-2 plugging instrument, fill the core crack with 190g of asphalt, and then add the prepared plugging slurry into the DL-2 plugging instrument. After heating the core with simulated fracture...

Embodiment 2

[0039] Component dosage:

[0040] Vinyl chloride resin: 4 parts by weight

[0041] Calcium carbonate particles (1-2mm): 6 parts by weight

[0042] Sepiolite fiber (0.5-1mm): 1 part by weight

[0043] Mica (0.1-0.5mm): 2 parts by weight

[0044] Calcium carbonate powder (300-400 mesh): 5 parts by weight

[0045] Heat the vinyl chloride resin to a molten state, add other plugging materials, mix evenly, cool to room temperature, and crush it into 2-3 mm small pieces with a pulverizer to obtain a coated plugging agent. Add 12 parts by weight of the coated plugging agent to 100 parts by weight of the bentonite slurry to prepare the plugging slurry, prepare 2000 mL of the plugging slurry according to the above formula, and set aside.

[0046] Install a 2mm simulated fracture core in the DL-2 plugging instrument, fill the cracks of the core with 380g of asphalt, and then add the prepared plugging slurry into the DL-2 plugging instrument. The simulated fractured core was heated t...

Embodiment 3

[0048] Component dosage:

[0049] Polypropylene resin: 5 parts by weight

[0050] Calcium carbonate particles (2-3mm): 7 parts by weight

[0051] Sepiolite fiber (1-2mm): 2 parts by weight

[0052] Mica (0.5-1mm): 1 part by weight

[0053] Calcium carbonate powder (300-400 mesh): 6 parts by weight

[0054] Heating the polypropylene resin to a molten state, adding other plugging materials, mixing evenly, cooling to room temperature, crushing into small pieces of 3-4 mm with a pulverizer, and obtaining a coated plugging agent. Add 14 parts by weight of the coated plugging agent to 100 parts by weight of bentonite slurry to prepare a plugging slurry, prepare 2000 mL of the plugging slurry according to the above formula, and set aside.

[0055] Install a 3mm simulated fracture core in the DL-2 plugging instrument, fill the cracks of the core with 570g of asphalt, and then add the prepared plugging slurry into the DL-2 plugging instrument. After heating the core with simulated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure endurance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com