Deformable plugging block, and preparation method and application thereof

A monomer and acrylamide technology, applied in the field of deformable plugging block and preparation, deformable plugging block, can solve the problems of difficult to achieve pressure bearing effect, prone to re-leakage, low plugging success rate, etc., to achieve overall Improve structural strength, increase plugging success rate, and improve construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 1. Preparation of deformable plugging block (gel plugging module)

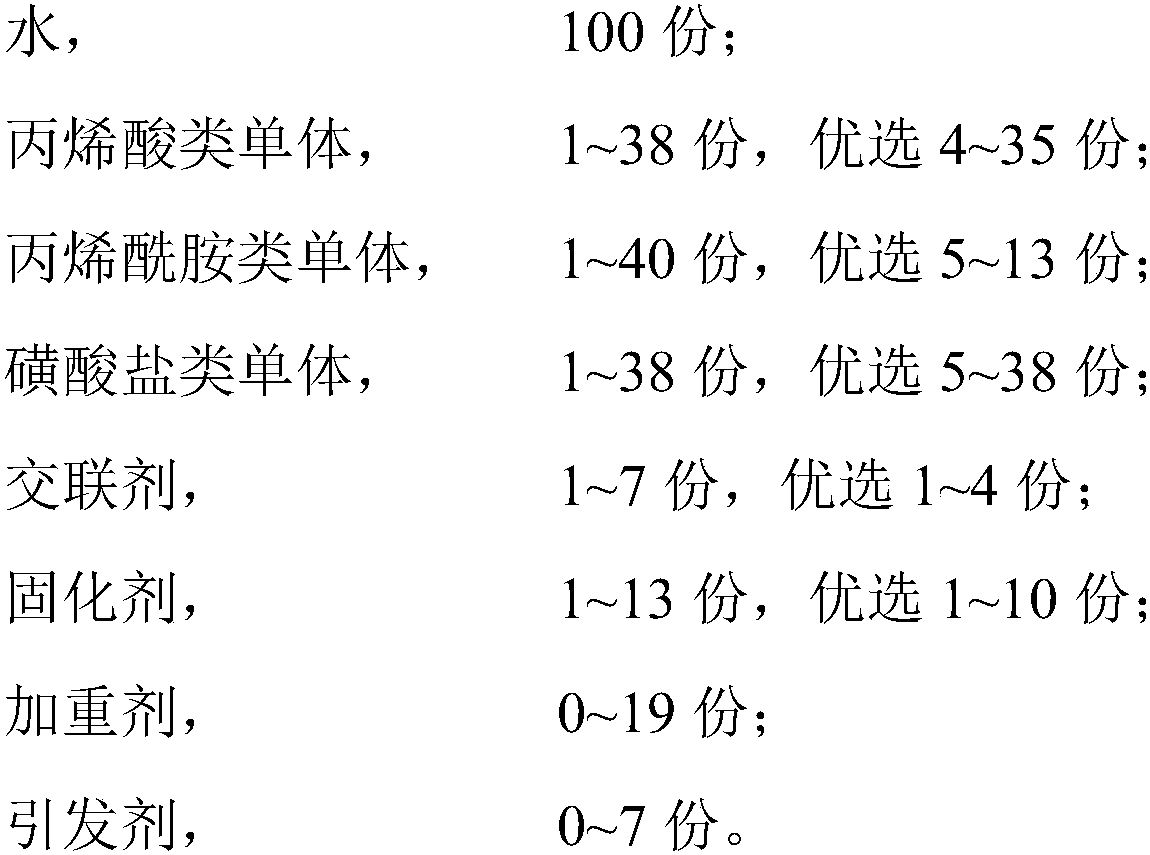

[0044] Weigh the following components in parts by weight:

[0045] Water: 100 parts by weight;

[0046] Acrylamide: 35 parts by weight;

[0047] Acrylic acid: 10 parts by weight;

[0048] 2-acrylamide-2-methylpropanesulfonic acid: 20 parts by weight;

[0049] N, N-methylenebisacrylamide: 5 parts by weight;

[0050] Cupric chloride: 7 parts by weight;

[0051] Sodium silicate: 3.5 parts by weight;

[0052] Calcium carbonate: 19 parts by weight;

[0053] Potassium persulfate: 1.75 parts by weight.

[0054] The specific preparation steps of the gel module are as follows:

[0055] First add water to the pre-made fixed mold, add N, N-methylenebisacrylamide, acrylic acid, acrylamide, 2-acrylamide-2-methylpropanesulfonic acid monomer into the water, and then stir to obtain Transition body solution A containing monomers; then add copper chloride, sodium silicate, and calcium carbonate to transition bod...

Embodiment 2

[0064] 1. Preparation of deformable plugging block (water-absorbing resin module)

[0065] Weigh the following components in parts by weight:

[0066] Water: 100 parts by weight;

[0067] Acrylamide: 30 parts by weight;

[0068] Acrylic acid: 10 parts by weight;

[0069] Sodium dodecylbenzenesulfonate: 10 parts by weight;

[0070] N, N-methylenebisacrylamide: 10 parts by weight;

[0071] Chromium chloride: 6 parts by weight;

[0072] Magnesium oxide: 3 parts by weight;

[0073] Barium sulfate: 10 parts by weight;

[0074] Azobisisobutyronitrile: 1.5 parts by weight.

[0075] The specific preparation steps of the water-absorbent resin module are: first add water to the pre-made fixed mold, add acrylic acid, acrylamide, and sodium dodecylbenzenesulfonate monomers to the water, and then add N, N-methylene base bisacrylamide to obtain mixture A; then sequentially add chromium chloride, magnesium oxide, and barium sulfate to mixture A, and continue stirring to obtain mixtur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com