Cage type well drilling leakage stopping device and well drilling leakage stopping method

A plugging method and cage technology, applied in the field of oil drilling, can solve the problems of reducing the success rate of plugging, rapid loss of high-density cement slurry, stuck drilling, etc. Guaranteed quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the drawings.

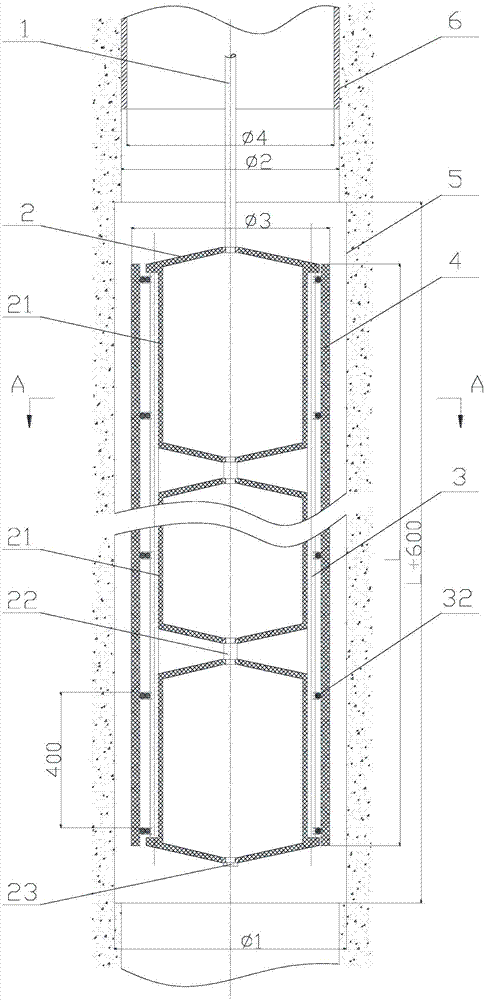

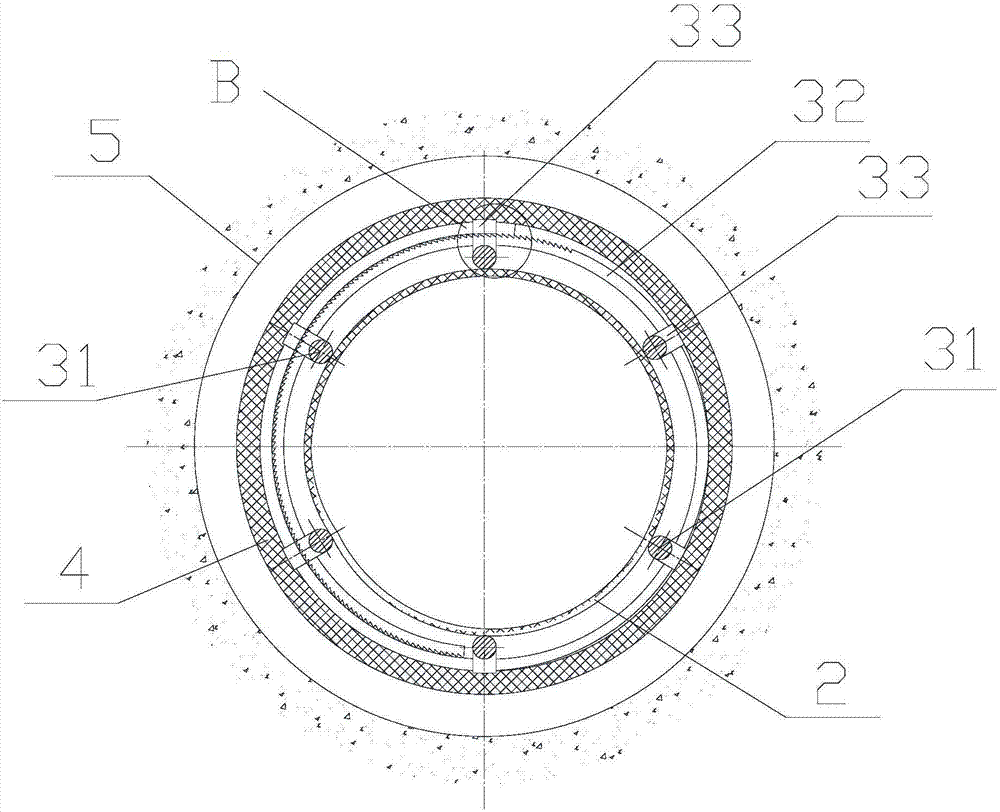

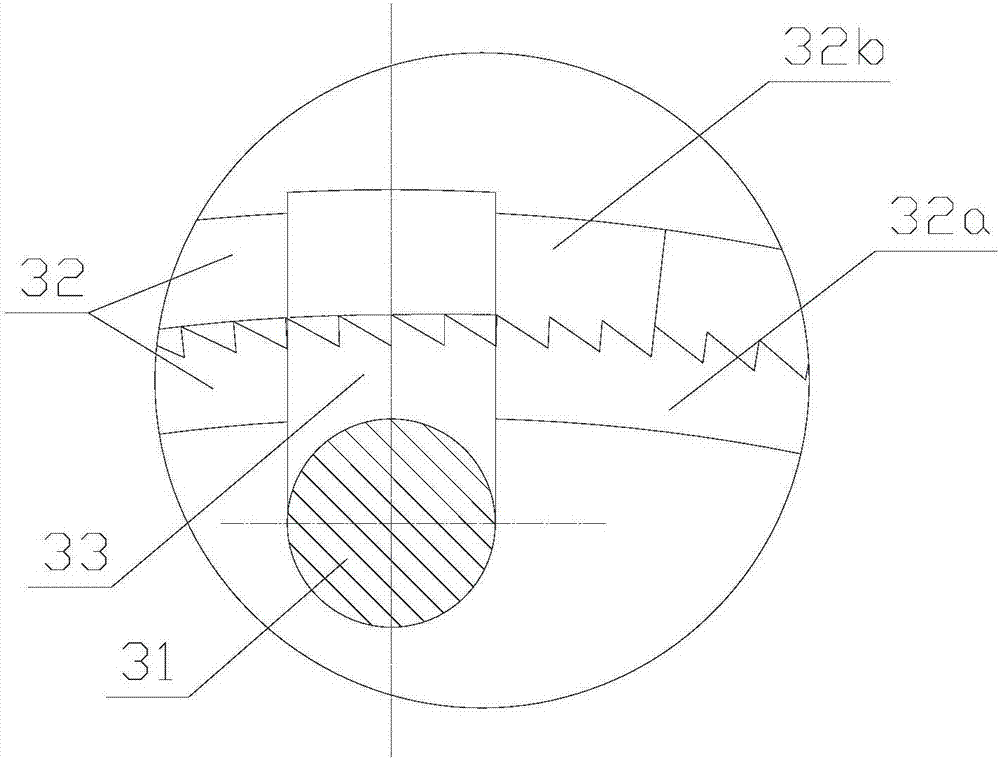

[0028] Such as figure 1 As shown, the cage type drilling leakage plugging device of the present invention includes a small continuous tubing 1, an expansion sleeve 2, a cage 3, and a sealing sleeve 4. The continuous small tubing 1 is connected to the expansion sleeve 2, and the expansion sleeve 2 is in a closed shape and continuously small. The oil pipe 1 can inject air and exhaust gas into the expansion sleeve 2 to realize the expansion and contraction changes of the expansion sleeve 2. The expansion sleeve 2 can be a whole, or as figure 1 As shown, the expansion sleeve 2 is formed by a plurality of identical expansion sub-sleeves 21 in series, and two ends of the expansion sub-sleeve 21 are respectively provided with matching joints to facilitate the series connection as required. The connecting pipe 22 is connected, wherein the expansion sleeve 21 at the head end is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com