Explosion-proof elevator cable for fire protection

An elevator cable and fire-fighting technology, which is applied in the field of elevator cables, can solve problems such as no drainage measures, failure to meet explosion-proof requirements, and inability to completely prevent interference, etc., to achieve the effect of avoiding electromagnetic interference, avoiding leakage discharge, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

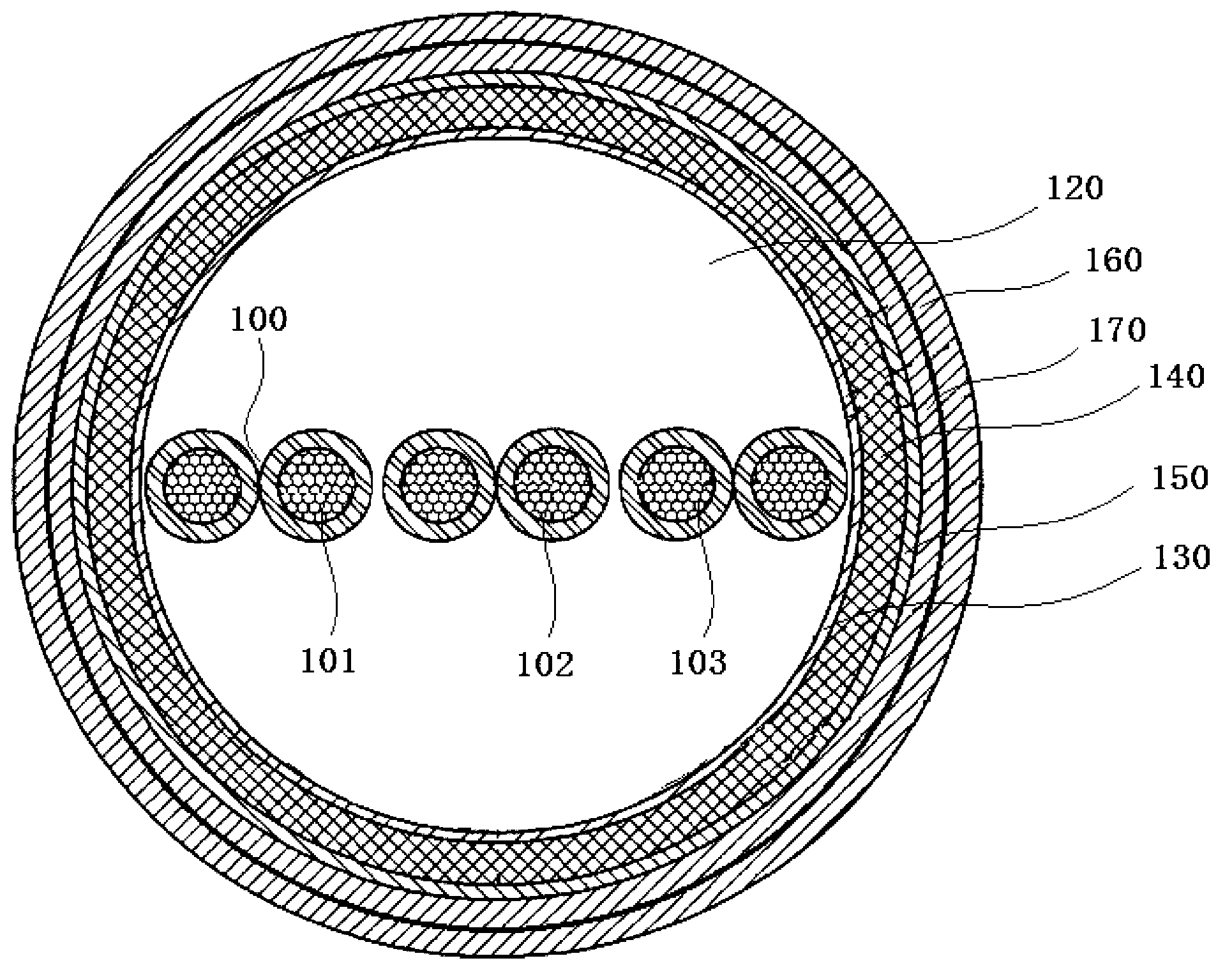

[0015] Such as figure 1 As shown, the fire-fighting explosion-proof elevator cable of the present invention includes a cable core 100, an elastic filling layer 120, an inner sheath 130, a tensile compression layer 140, a metal shielding layer 150 and an outer sheath 160; 100 includes several independent control lines 101, power lines 102 and twisted-pair communication conversion video lines 103, the control lines 101, power lines 102 and twisted-pair communication conversion video lines 103 are provided with an elastic filling layer 120, outside the elastic filling layer 120 Wrapped with an inner sheath 130 for the inner layer to protect the cable core, the outer side of the inner sheath 130 is sequentially provided with a tensile and compressive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com