Gas driving membrane turnover type normally closed valve

A driving membrane, flip-type technology, applied in the direction of valve details, safety valves, balance valves, etc., can solve the problems of gas-driven valve sealing performance that cannot meet the requirements, large volume, etc., to ensure sealing reliability, enhance sealing reliability, The effect of reducing drag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

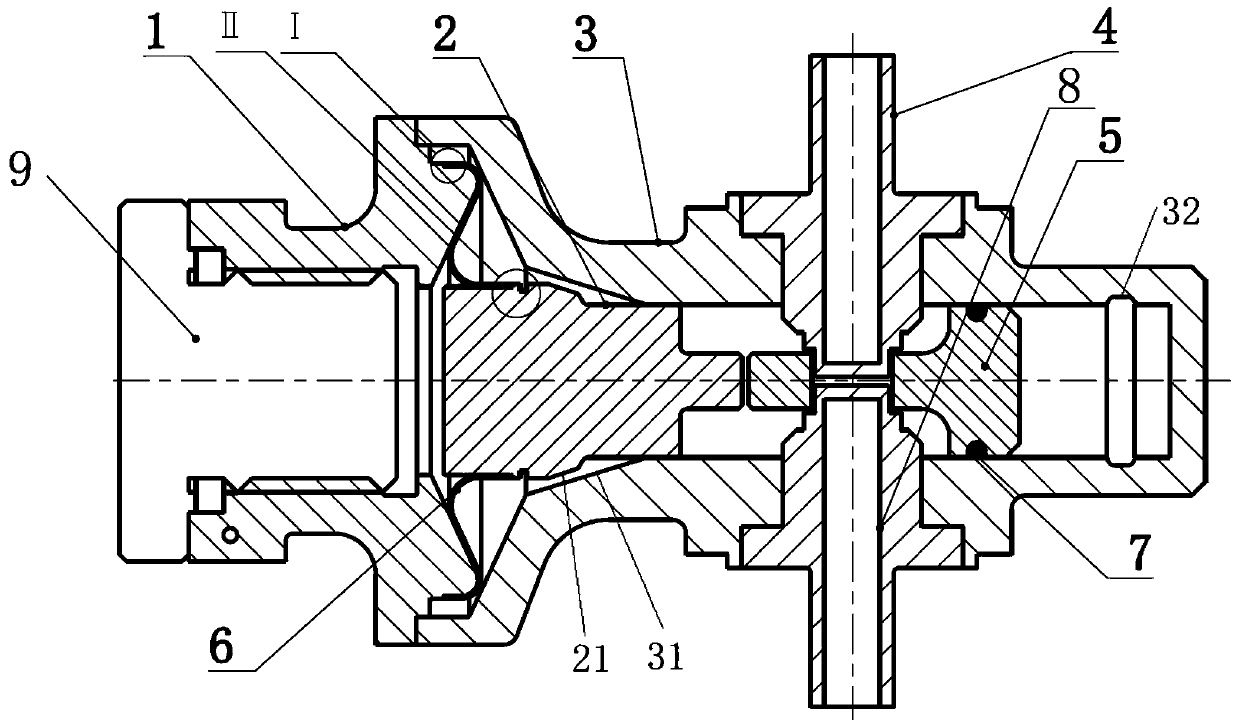

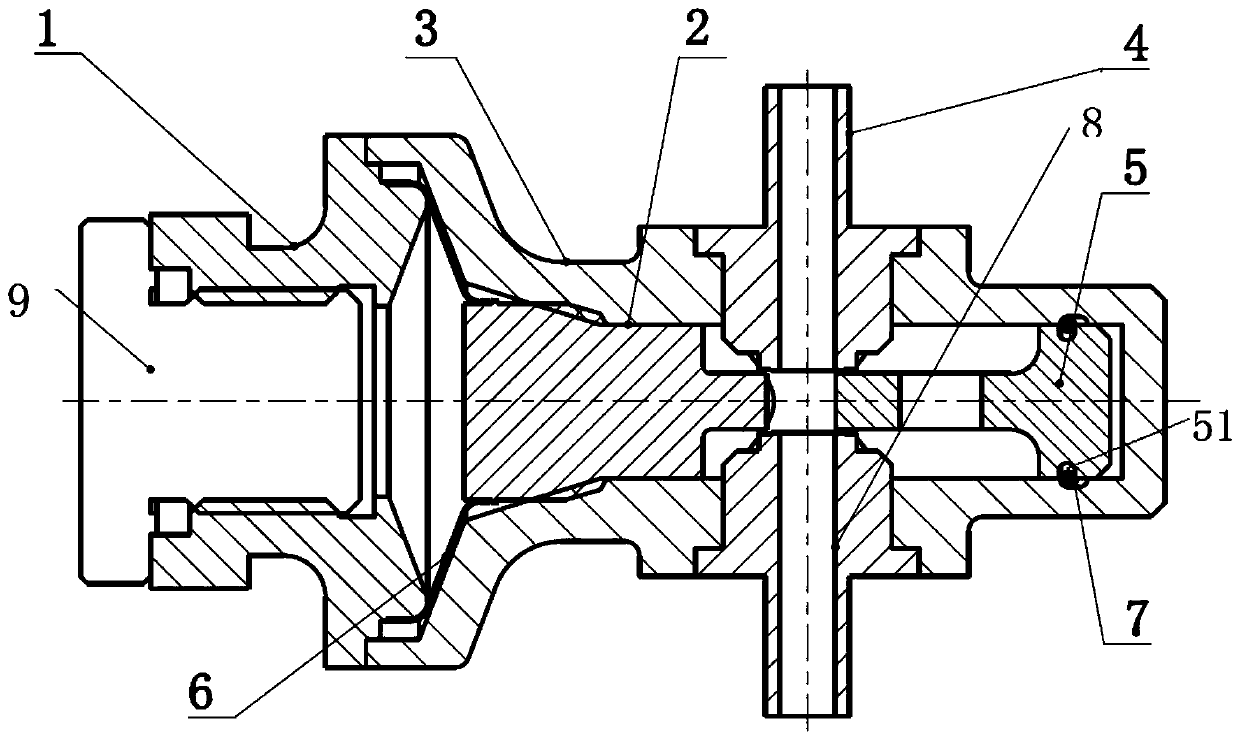

[0021] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

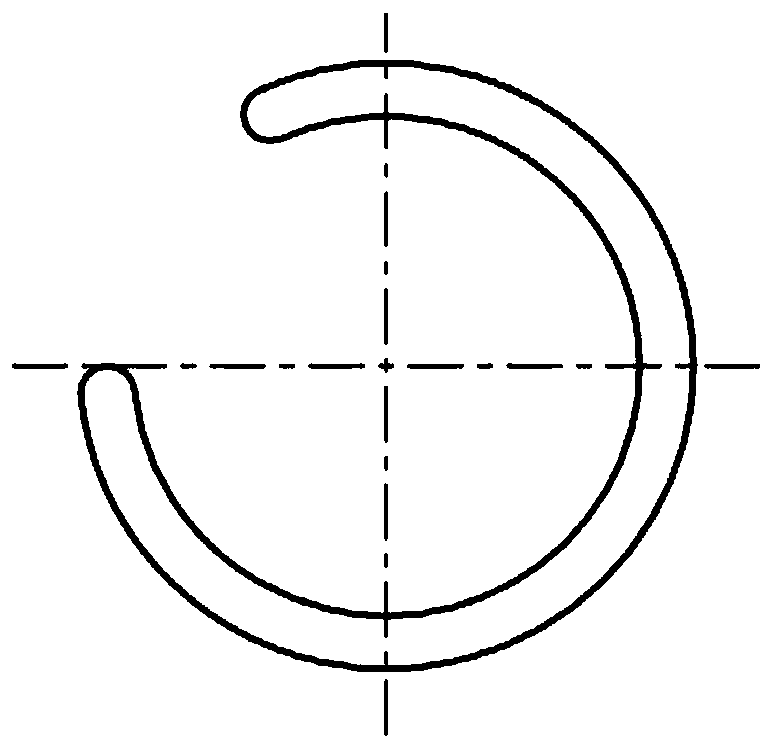

[0022] In order to improve the pressure adaptability and temperature adaptability of the existing multi-channel non-metallic redundant dynamic seals, and improve the sealing characteristics after the piston and the valve body are wedged tightly, the invention provides a gas-driven diaphragm flip-type normally closed valve. The normally closed valve uses a metal diaphragm to seal the gas to prevent leakage. It adopts a split structure of the piston and the cutter to distribute the energy of the gas. It adopts an elastic snap ring structure to effectively limit the cutter and prevent backlash. The invention can be applied in the high-pressure medium control pipeline required for long-term storage.

[0023] Such as Figure 1 to Figure 5 As shown, the gas-driven diaphragm flip-type normally closed valve provided by the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com