Jacket type water pressure testing device of large-caliber glass steel pipeline

A technology of hydraulic test and glass fiber reinforced plastic, which is applied in measuring device, using stable tension/pressure test material strength, instrument, etc., can solve the problems of cumbersome pressure test operation, large floor space and high cost, and save time. and process, small footprint, fast hydraulic test effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present application will be described in detail below in conjunction with specific embodiments.

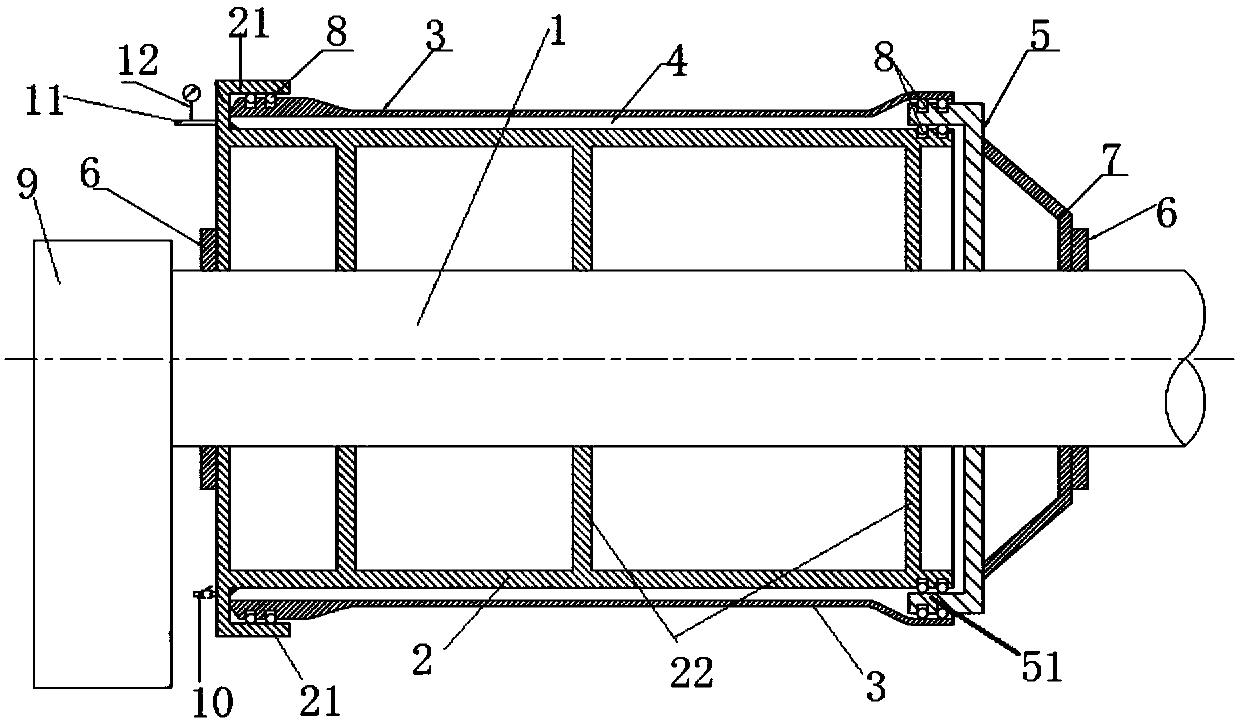

[0019] Such as figure 1 A jacketed hydrostatic test device for a large-diameter FRP pipe is shown, which includes a cantilever arm 1 and a sleeve 2 sleeved outside the cantilever arm 1, the pipeline to be tested 3 is sleeved outside the sleeve 2, and the sleeve 2 and The two ends of the pipeline 3 to be tested are sealed and connected, and the middle section forms a cavity interlayer 4 for hydraulic testing. Wherein, the cantilever arm 1 is cylindrical, and is vertically installed on the fixed support 9 in the vertical direction; the sleeve 2 is a steel sleeve, which can be installed directly from the free end of the cantilever arm 1 by sliding-in sleeve. The wall has a double-layer structure, and a pressure-bearing bracket 22 is provided between the inner wall and the outer wall; the edge of the sleeve 2 close to the fixed end of the cantilever arm 1 is integrally pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com