Preparation and application of oil-water separation net membrane with different wettability

A technology of oil-water separation omentum and wettability, applied in the direction of liquid separation, separation method, grease/oily substance/suspton removal device, etc., to achieve the effect of good cycle stability, high separation efficiency and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

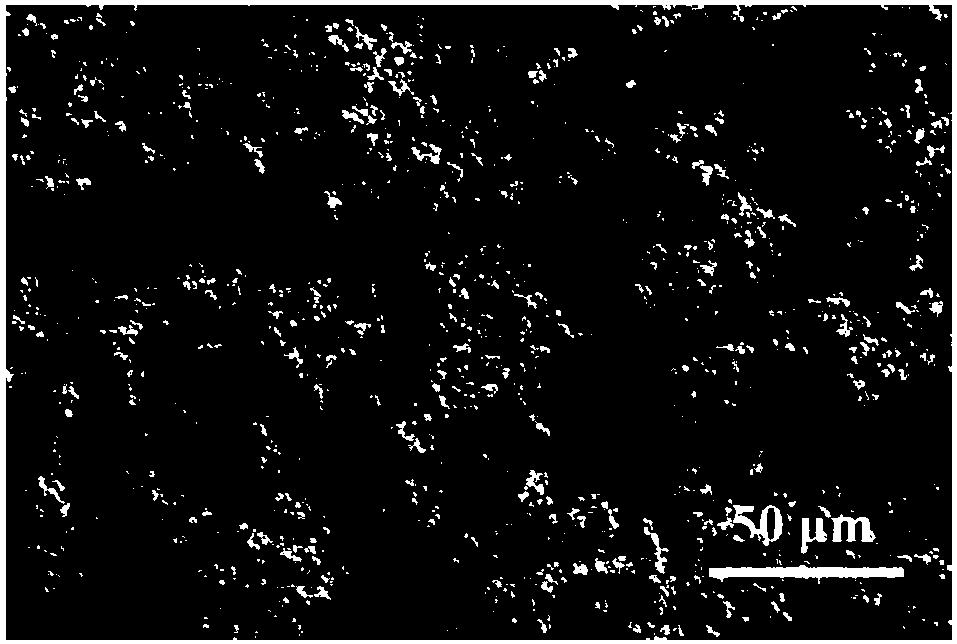

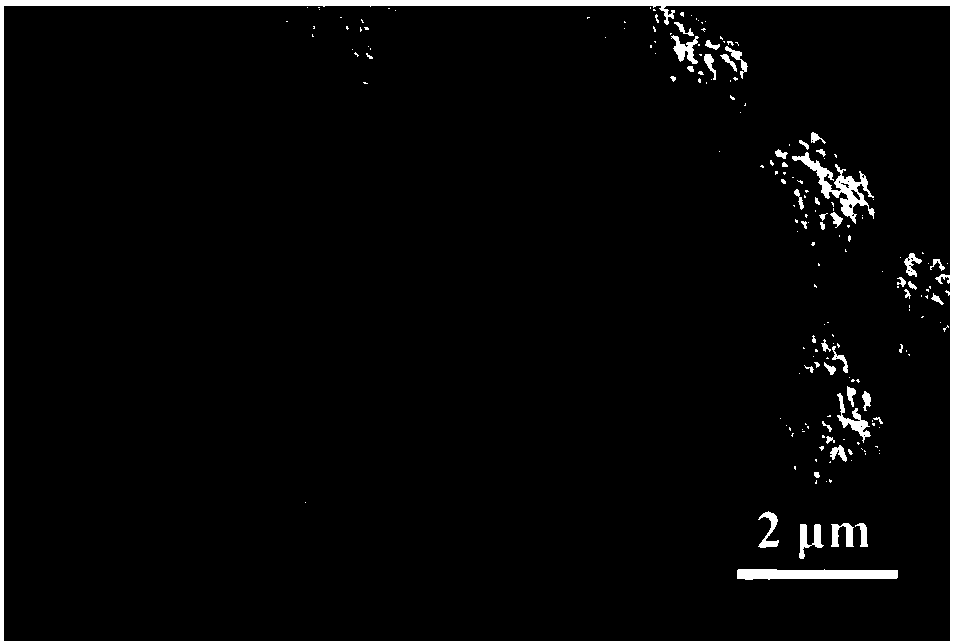

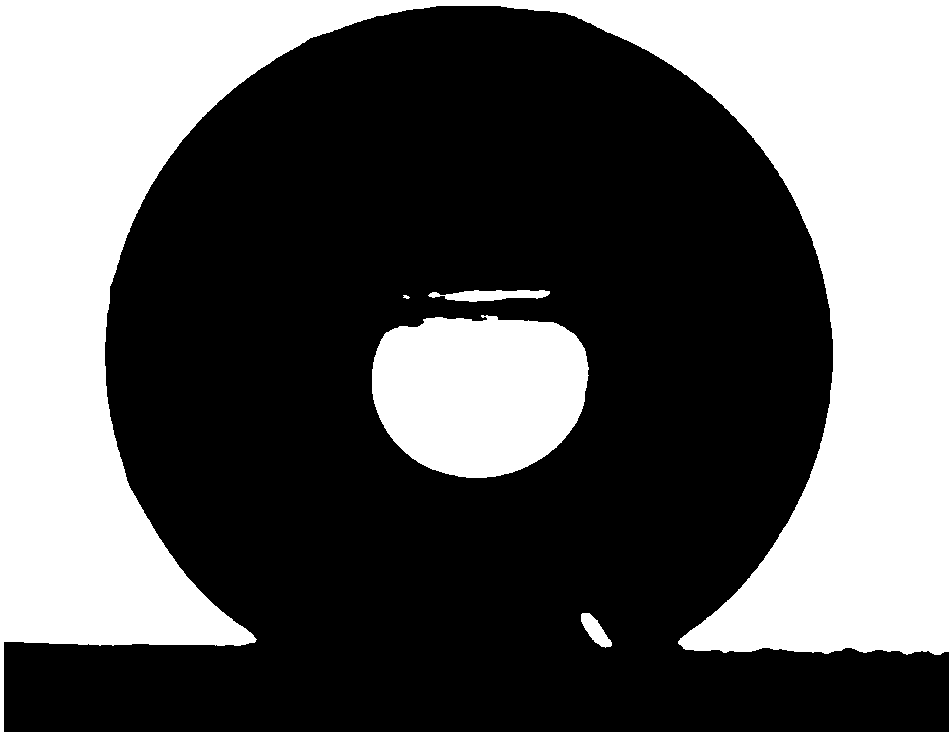

[0040] Example 1, One-step chemical vapor deposition method to prepare superhydrophobic superoleophilic and sub-oil superhydrophobic oil-water separation omentum

[0041] (1) Cut the 500-mesh stainless steel mesh into many small pieces (3cm×3cm), then ultrasonically clean them with acetone, absolute ethanol, and deionized water for 5 minutes, and dry them at room temperature;

[0042] (2) Lay the stainless steel mesh dried in step (1) on a cylindrical crucible (inner diameter 3cm, height 5cm) filled with 0.5g liquid polydimethylsiloxane, and then put them into the muffle In the furnace, calcined at high temperature. The calcination temperature of the muffle furnace is set at 350°C, the heating rate is 10°C / min, and the calcination time is 2h. After the muffle furnace is naturally cooled to room temperature, it is taken out to obtain a superhydrophobic, superoleophilic and sub-oil superhydrophobic oil-water separation omentum.

[0043] The pore size of the oil-water separatio...

Embodiment 2

[0046] Example 2, One-step chemical vapor deposition method to prepare superhydrophobic superoleophilic and sub-oil superhydrophobic oil-water separation omentum

[0047] (1) Cut the 120-mesh aluminum mesh into many small pieces (3cm×3cm), then ultrasonically clean them with acetone, absolute ethanol, and deionized water for 5 minutes, and dry them at room temperature;

[0048] (2) Lay the aluminum mesh dried in step (1) on a cylindrical crucible (inner diameter 3cm, height 5cm) filled with 2g of liquid polydimethylsiloxane, and then put them into the muffle furnace Medium, high temperature calcination. The calcination temperature of the muffle furnace is set at 300°C, the heating rate is 5°C / min, and the calcination time is 2h. After the muffle furnace is naturally cooled to room temperature, it is taken out to obtain a superhydrophobic, superoleophilic and sub-oil superhydrophobic oil-water separation omentum.

[0049] The pore size of the oil-water separation mesh obtained ...

Embodiment 3

[0052] Example 3, One-step chemical vapor deposition method to prepare superhydrophobic superoleophilic and sub-oil superhydrophobic oil-water separation omentum

[0053] (1) Cut the 300-mesh glass fiber mesh into many small pieces (3cm×3cm), then ultrasonically clean them with acetone, absolute ethanol, and deionized water for 5 minutes respectively, and dry them at room temperature;

[0054] (2) Lay the glass fiber mesh dried in step (1) on a cylindrical crucible (inner diameter 3 cm, height 5 cm) filled with 1.5 g of liquid polydimethylsiloxane, and then put them into the Furnace, high temperature calcination. The calcination temperature of the muffle furnace is set at 400°C, the heating rate is 8°C / min, and the calcination time is 2h. After the muffle furnace is naturally cooled to room temperature, it is taken out to obtain a superhydrophobic, superoleophilic and sub-oil superhydrophobic oil-water separation omentum.

[0055] The pore size of the oil-water separation me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com