Medium-pressure steel wire reinforced plastic pipeline and pipe fitting connecting method

A technology of reinforced plastic and connection method, which is applied in the direction of pipeline connection arrangement, pipe/pipe joint/pipe fitting, mechanical equipment, etc., to avoid leakage and better withstand pressure.

Inactive Publication Date: 2012-01-18

江苏联冠高新技术有限公司

View PDF3 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The medium-pressure steel wire reinforced plastic pipe and pipe fitting connection method of the present invention develops a medium-pressure pipe and construction connection scheme for engineering, which solves the problem of pipe fitting connection in the application of large-diameter high-pressure steel wire reinforced plastic pipes. The diameter of the pipe can reach 400mm, and the pressure It can reach 10Mpa, which can be well used in engineering environments with high requirements such as emergency transportation

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0011] 1. Steel wire reinforced plastic pipe with a diameter of 219mm, the burst test pressure reaches 16.8MPa, and the connecting part of the pipe fittings is intact;

[0012] 2. Steel wire reinforced plastic pipe with a diameter of 315mm, the burst test pressure reaches 14.6MPa, and the connection part of the pipe fittings is intact.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Login to View More

Abstract

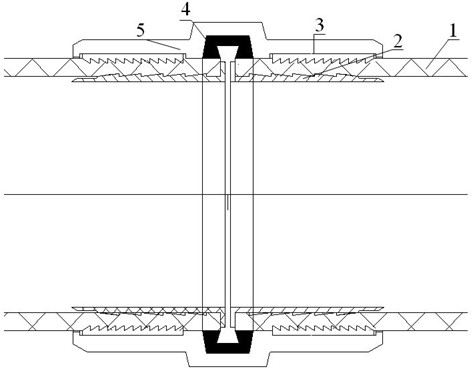

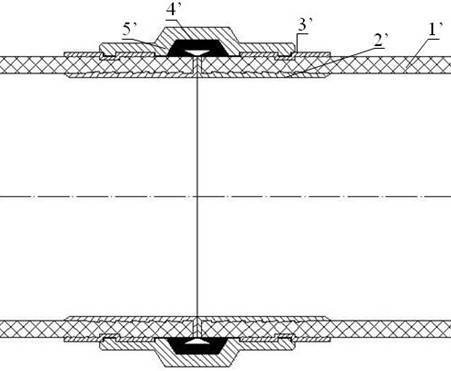

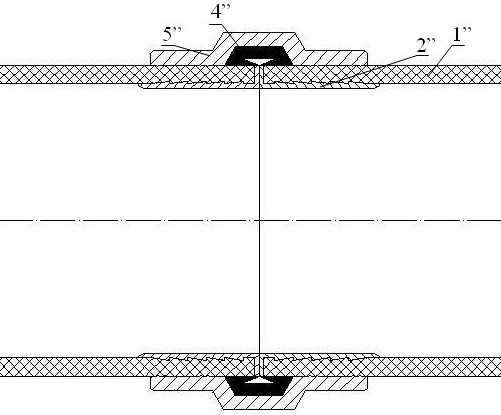

The invention discloses a medium-pressure steel wire reinforced plastic pipeline and a pipe fitting connecting method. The medium-pressure steel wire reinforced plastic pipeline comprises pipes (1, 1' and 1''), inner bushings (2, 2' and 2''), fastening sleeves (3 and 3'), sealing rings (4, 4' and 4'') and connecting members (5, 5' and 5''), wherein the inner bushings (2, 2' and 2'') are arranged inside ports of the pipes (1, 1' and 1'') for supporting; the fastening sleeves (3 and 3') are fixed on the surfaces of the ports of the pipes (1, 1' and 1'') through a buckling device; the sealing rings (4, 4' and 4'') are sleeved at the ports of the pipes (1, 1' and 1''); and the connecting members (5, 5' and 5'') are connected to the fastening sleeves (3 and 3') or directly used for fastening the pipes (1, 1' and 1''). According to the medium-pressure steel wire reinforced plastic pipeline and the pipe fitting connecting method which are disclosed by the invention, an engineering medium-pressure pipeline and construction connecting scheme is developed, and the problem of pipe fitting connection in the application of the heavy-caliber high-pressure steel wire reinforced plastic pipeline is solved; and the caliber of the pipeline can reach 400mm, and the pressure can reach 10Mpa. The medium-pressure steel wire reinforced plastic pipeline and the pipe fitting connecting method can be better applied to engineering environments with high requirements, such as emergency transportation and the like.

Description

technical field [0001] The invention relates to a medium-pressure steel wire reinforced plastic pipe and a pipe fitting connection method, which can be well applied to engineering environments with high requirements such as emergency transportation. Background technique [0002] Steel wire reinforced plastic pipe is a new material pipe product independently developed by our country. Based on the manufacturing experience of traditional metal and non-metal composite pipes, the plastic main body and metal skeleton are organically combined into an overall reinforced structure, which retains the flexibility of plastic pipes. At the same time, the strength of steel material is introduced, and the advantages of plastic material and metal material are brought into full play. Due to the many advantages of steel wire reinforced plastic pipes, it has been widely used in engineering construction in recent years. Its performance is very good to meet the construction of municipal and indu...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F16L47/00

Inventor 严为群黄学祥王德禧钱德承陈勇

Owner 江苏联冠高新技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com