Safety can for preventing explosion of liquefied petroleum gas cylinder

A liquefied petroleum gas and safety tank technology, which is applied to the purpose of gas treatment/storage, the method of container discharge, gas/liquid distribution and storage, etc. The effect of eliminating safety hazards, avoiding temperature increases, and reducing the possibility of explosions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

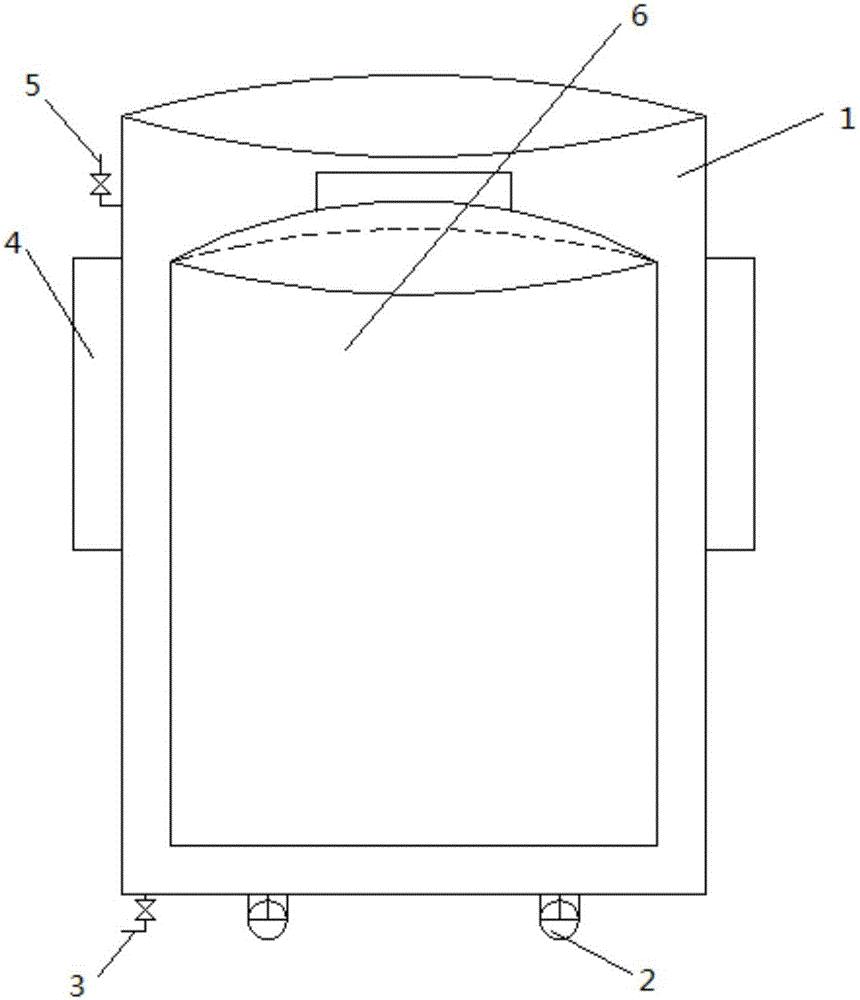

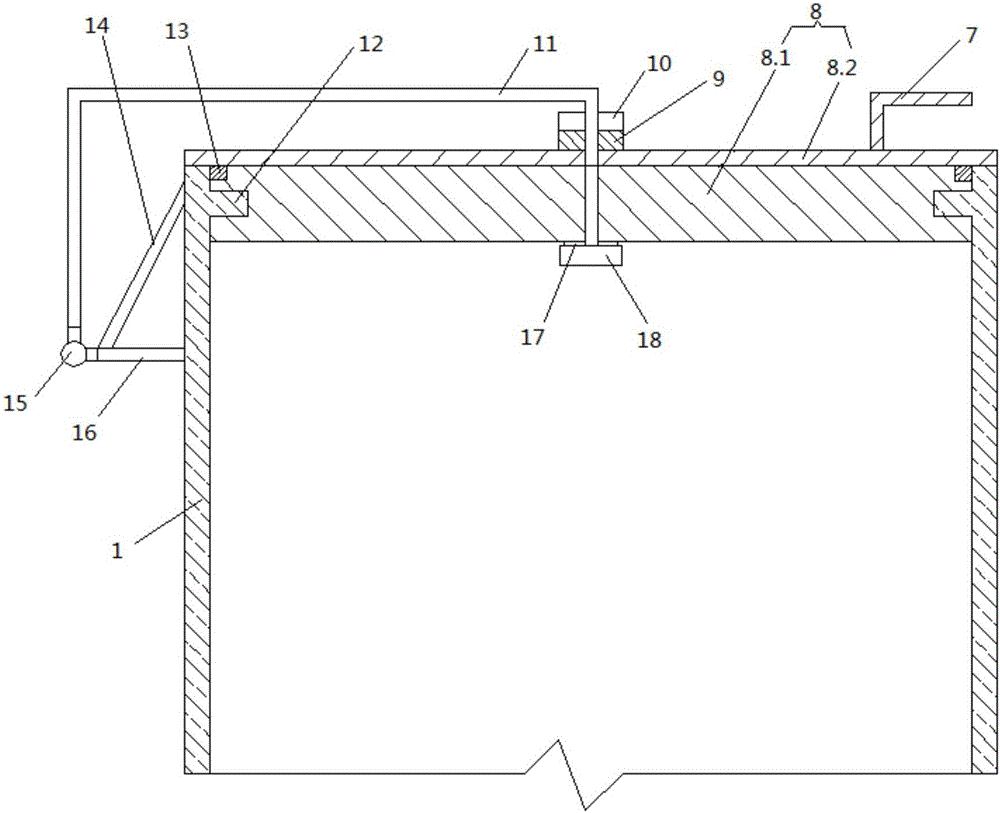

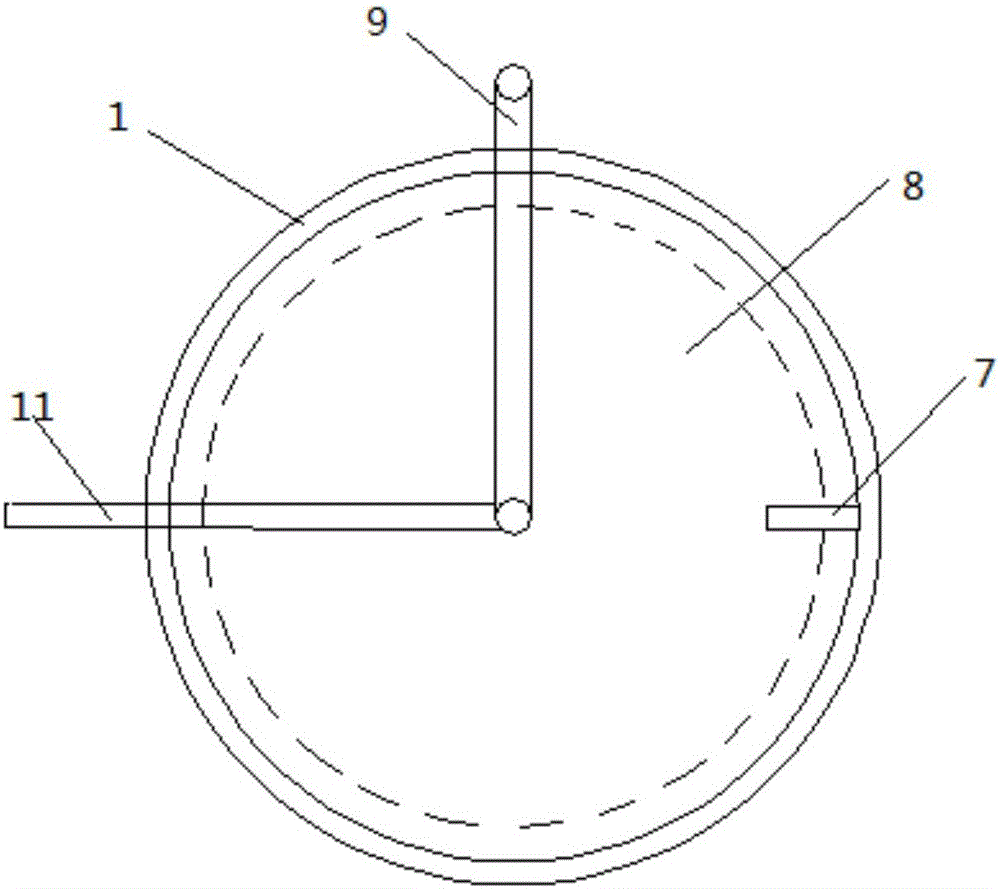

[0023] Such as figure 2 , image 3 and Figure 5 As shown, an explosion-proof safety tank for liquefied petroleum gas cylinders includes a tank body 1 and a tank cover 8, the tank cover 8 is a T-shaped plug cover, and the shoulder 8.2 of the tank cover 8 covers the opening at the top of the tank body 1 , the plug portion 8.1 of the tank cover 8 extends into the tank body 1 from the opening at the top of the tank body 1, and the plug portion 8.1 of the tank cover 8 is sleeved with a first sealing ring 13 near the shoulder 8.2 of the tank cover 8; The upper part of the outer wall of the body 1 is fixedly provided with a support rod 16, and the middle part of the tank cover 8 is vertically rotated to be provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com