Circulating blowing type electric welding work case for pipeline operation

A blower type, assembly line technology, applied in the field of circulating blower type electric welding work box for assembly line operation, can solve the problems of health damage of surrounding personnel, expensive inert gas, pollution of surrounding environment, etc., to protect workers' health and safety , the effect of protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

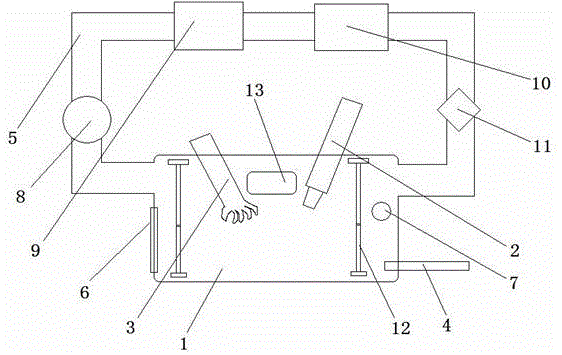

[0034] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0035] As shown in the figure, a circulating blast type electric welding work box for assembly line operation of the present invention includes a folding electric welding box 1 that can be filled and discharged, and the electric welding nozzle pipe 2 and an inward-turning type The grabbing glove 3 and the electric welding nozzle pipe 2 have a total electric welding equipment installation space. The electric welding nozzle pipe 2 and the inward-turning grabbing glove 3 are all movably connected to the folding electric welding box 1, and the connection with the folding electric welding box 1 is also sealed. At the same time, it is also convenient for the movement of the electric welding nozzle pipe 2 and the inward-turning grasping glove 3 in the folding electric welding box 1 without hindrance;

[0036] The folding electric welding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com