Novel transparent high-level porcelain mud material and porcelain product thereof

A technology for ceramic mud and ceramic products, applied in the field of new transparent high-grade ceramic mud and its ceramic products, can solve the problems of many "three wastes", many production processes, and high energy consumption, and achieve less three wastes, fewer production processes, and energy consumption. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] A kind of embodiment of novel transparent high-grade ceramic mud material of the present invention and its ceramic product is:

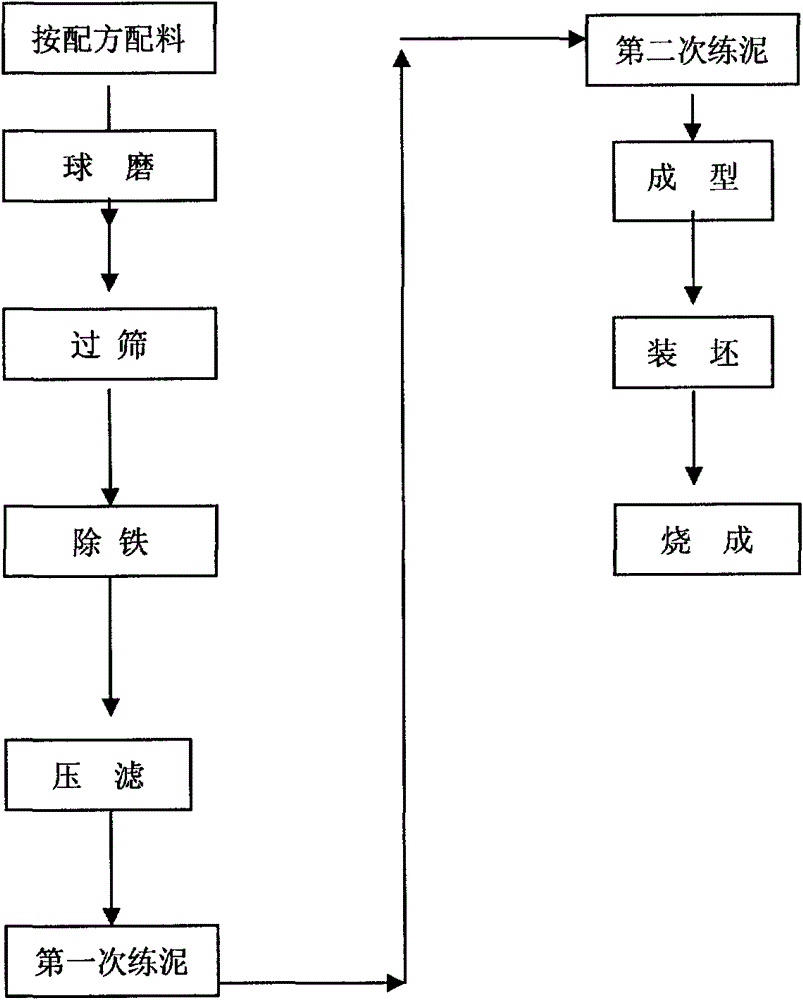

[0011] Weigh kaolin: 280kg, potassium feldspar: 100kg, albite: 50kg, quartz 370kg, hydroxycalcium phosphate 155kg, spodumene 20kg, talc 25kg, a total of 1000kg, accurate to 1%, put the above raw materials into the charging amount 1.0 In the 1-ton ball mill, (material: ball: water = 1:1:0.8) ball mill until the fineness is less than 0.5% of the net balance of the 10,000-hole sieve, three times of sieving to remove iron, and the mud cake after pressing is subjected to secondary mud refining (After the first mud refining, it can also be aged), and then molded and dried to form a green body, and then fired into a new transparent high-grade ceramic product in an oxidizing atmosphere at 1270°C-1310°C. The physical properties of this ceramic product have been tested as follows: thermal stability: 140°C-20°C water does not crack; glaze hardness ≥ 580k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com