Preparation method of mud for sanitary porcelain large-piece products

A technology for sanitary ceramics and mud, applied in the field of ceramic products, can solve the problems of low plasticity and large bending deformation, and achieve the effects of long service life, small hygroscopic expansion and guaranteeing stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The raw materials and the weight percentages of the raw materials used in the mud are: Xinkemei wash ball clay 12.8%, Lulong feldspar 17.8%, rich sandstone 6.2%, porcelain powder 4.0%, wollastonite 2.0%, kaolinite 5.4%, Zhangzhou Wash soil 5.0%, Zuoyun wash soil 7.2%, Zhangcun soil 10.0%, Feitianyan washed mud 4.3%, Xinyao washed mud 9.5%, GF-EB washed mud 6.6%, GF-36 washed mud 9.2%.

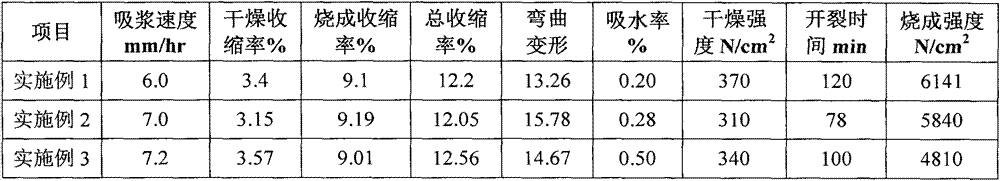

[0019] The physical and firing properties of the mud in this example are as follows: the suction speed is 6.0mm / hr, the drying shrinkage is 3.4%, the firing shrinkage is 9.1%, the total shrinkage is 12.2%, the bending deformation is 13.26%, the water absorption is 0.20%, and it is dry. Strength 370N / cm 2 , Cracking time 120min, firing strength 6141N / cm 2 .

Embodiment 2

[0021] The raw materials used in the mud and the weight percentages of raw materials are: Xinkemei wash ball clay 8%, Lulong feldspar 17.8%, rich sandstone 6.2%, porcelain powder 4.0%, wollastonite 2.0%, kaolinite 8.2%, Zhangzhou Wash soil 5.0%, Zuoyun wash soil 7.2%, Zhangcun soil 12.0%, Feitianyan washed mud 4.3%, Xinyao washed mud 9.5%, GF-EB washed mud 6.6%, GF-36 washed mud 9.2%.

[0022] The physical and firing properties of the mud in this example are as follows: the suction speed is 7.0mm / hr, the drying shrinkage is 3.15%, the firing shrinkage is 9.19%, the total shrinkage is 12.05%, the bending deformation is 15.78%, the water absorption is 0.28%, and the drying Strength 310N / cm 2 , Cracking time 78min, firing strength 5840N / cm 2 .

Embodiment 3

[0024] The raw materials and the weight percentages of the raw materials used in the mud are: Xinkemei wash ball clay 12.8%, Lulong feldspar 12.8%, rich sandstone 8.2%, porcelain powder 4.0%, wollastonite 2.0%, kaolinite 5.4%, Zhangzhou Washing soil 3.0%, Zuoyun washing soil 7.2%, Zhangcun soil 15.0%, Feitianyan washing mud 2.0%, Xinyao washing mud 11.8%, GF-EB washing mud 6.6%, GF-36 washing mud 9.2%.

[0025] The physical and firing properties of the mud in this example are as follows: the suction speed is 7.2mm / hr, the drying shrinkage is 3.57%, the firing shrinkage is 9.01%, the total shrinkage is 12.56%, the bending deformation is 14.67%, the water absorption is 0.50%, and the drying Strength 340N / cm 2 , Cracking time 100min, firing strength 4810N / cm 2 .

[0026] Table 1 The raw material formulas of the 3 examples (% by weight)

[0027] raw material name

Example 1

Example 2

Example 3

Xinkemei Ball

12.8

8

12.8

Lulong feldspar

17.8

17.8

12.8

Rich sandstone

6.2

6.2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com