Method for recovering fine catalyst powder to repelletize

A catalyst and fine powder technology, which is applied in the coal chemical industry to reduce dust emission and cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

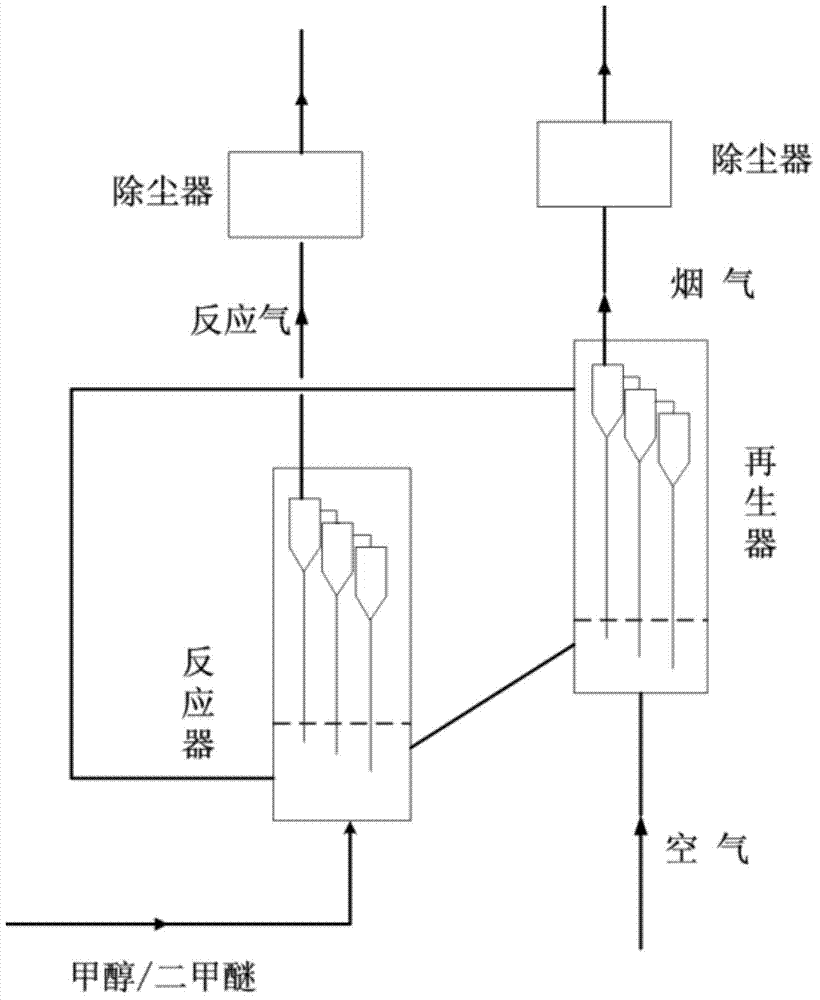

[0027] Attached below figure 1 The present invention is described further:

[0028] In alcohol ether to olefins fluidized bed system (see figure 1 ) to achieve the following process:

[0029] (1) Fill the alcohol ether to olefin catalyst with a certain abrasion strength in the reaction regeneration fluidized bed system. Perform cyclic reaction regeneration process;

[0030] (2) Alcohol ether to olefin catalyst is in contact with alcohol ether in the reactor to catalyze the conversion of alcohol ether into olefin products; the catalyst continuously rubs against other catalyst particles, walls and flowing gas for a long time. As the reaction time increases, the wear strength of the catalyst decreases, which leads to the catalyst being broken into smaller particles and a large amount of fine powder; the smaller particles return to the fluidized system for reaction through the action of the three-stage cyclone Regeneration, but a large amount of fine powder cannot be discharge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com