Cyclone separating device and uses thereof

A cyclone separator and solid separation technology, which is applied to cyclone devices, devices whose axial directions of cyclones can be reversed, etc., can solve the problems of aggravating boiler ash collection, waste of energy, and high catalyst concentration, and achieves convenient installation and piping, The effect of saving renovation cost and good anti-wear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

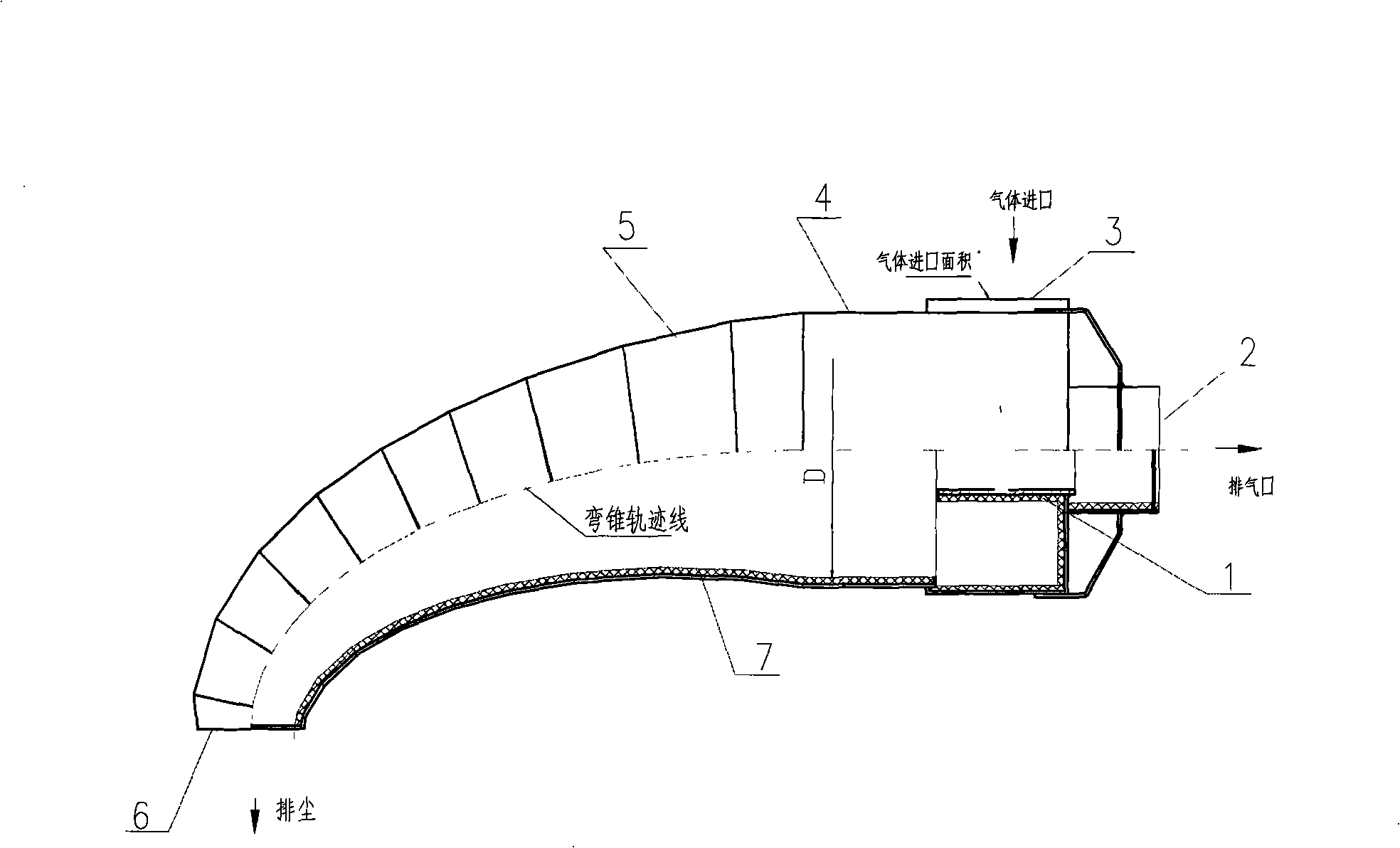

[0034] The three-rotation dust exhaust system of a fluidized catalytic cracking unit in a petrochemical plant needs to add a four-rotor with a diameter of 800 mm for the separation, recovery and discharge of spent catalyst fines. The effective space from the bottom of the three-rotation to the top of the middle fine powder tank is 1.8 meters, and the operating temperature is 550~600℃. It adopts the curved cone and four-rotation. According to the size of the four-rotation plane space, there are two piping layout schemes. Figure 5:

[0035] Figure 5 is a large elbow piping scheme. The pipeline occupies more space and space. The calculation and layout of the thermal expansion stress of the piping system are more complicated, but it has a long service life and safe operation. The four-spin system can be safely operated for more than 10 years. It can be used when the four-rotation plane space is large.

[0036] Figure 4 is the expansion joint piping scheme, which uses the expansion joi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com