Patents

Literature

35results about How to "Reduce dust collection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

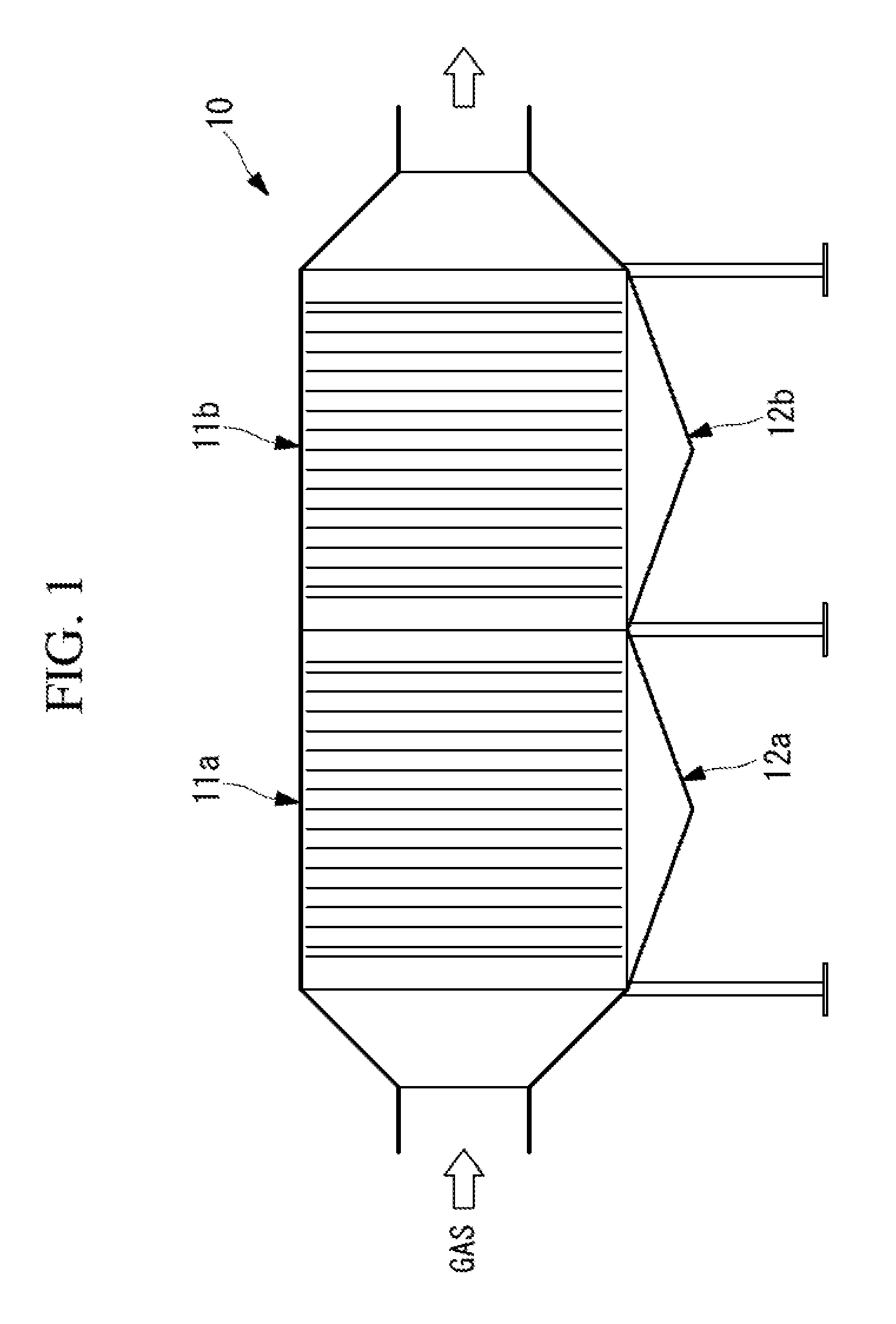

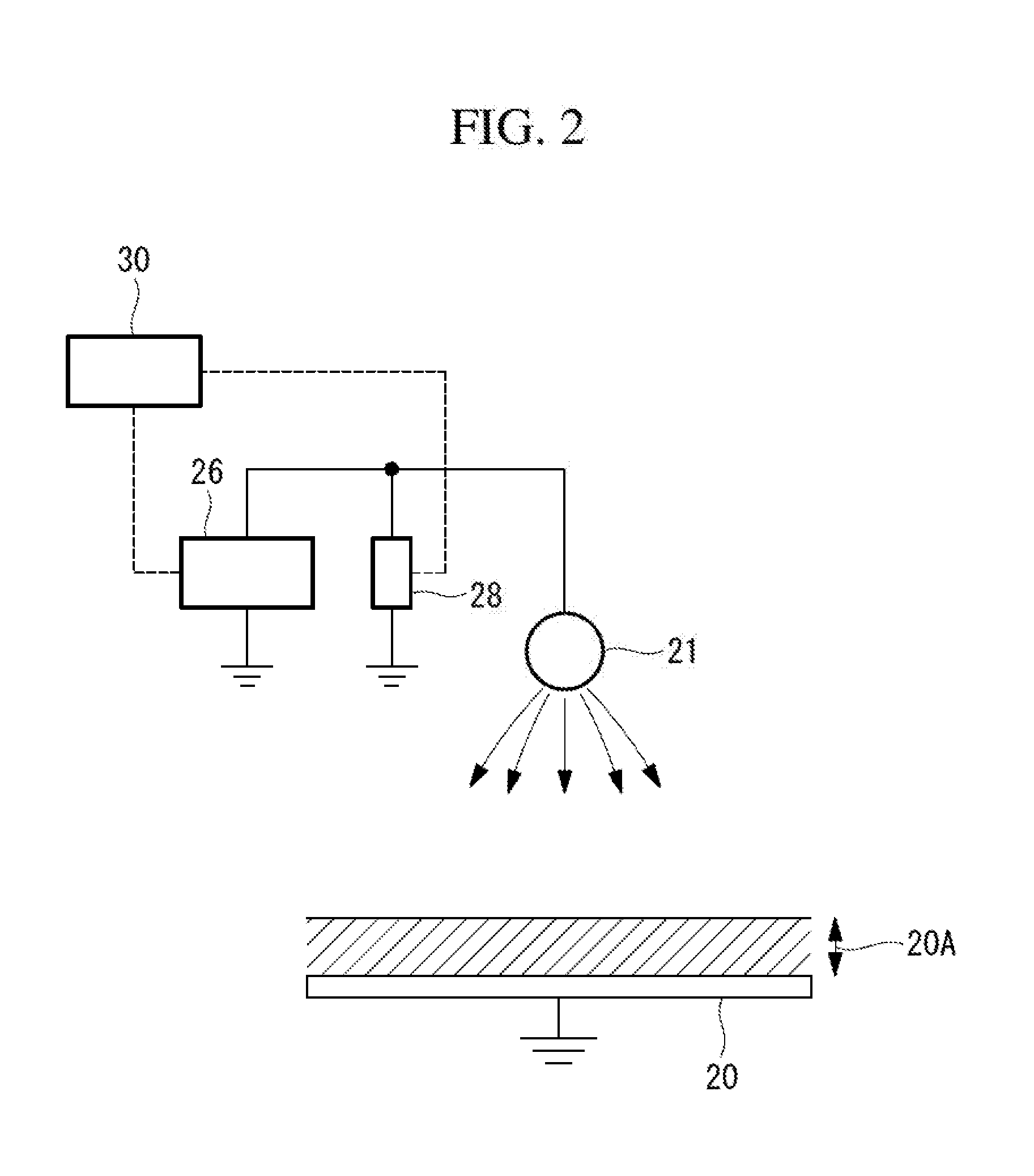

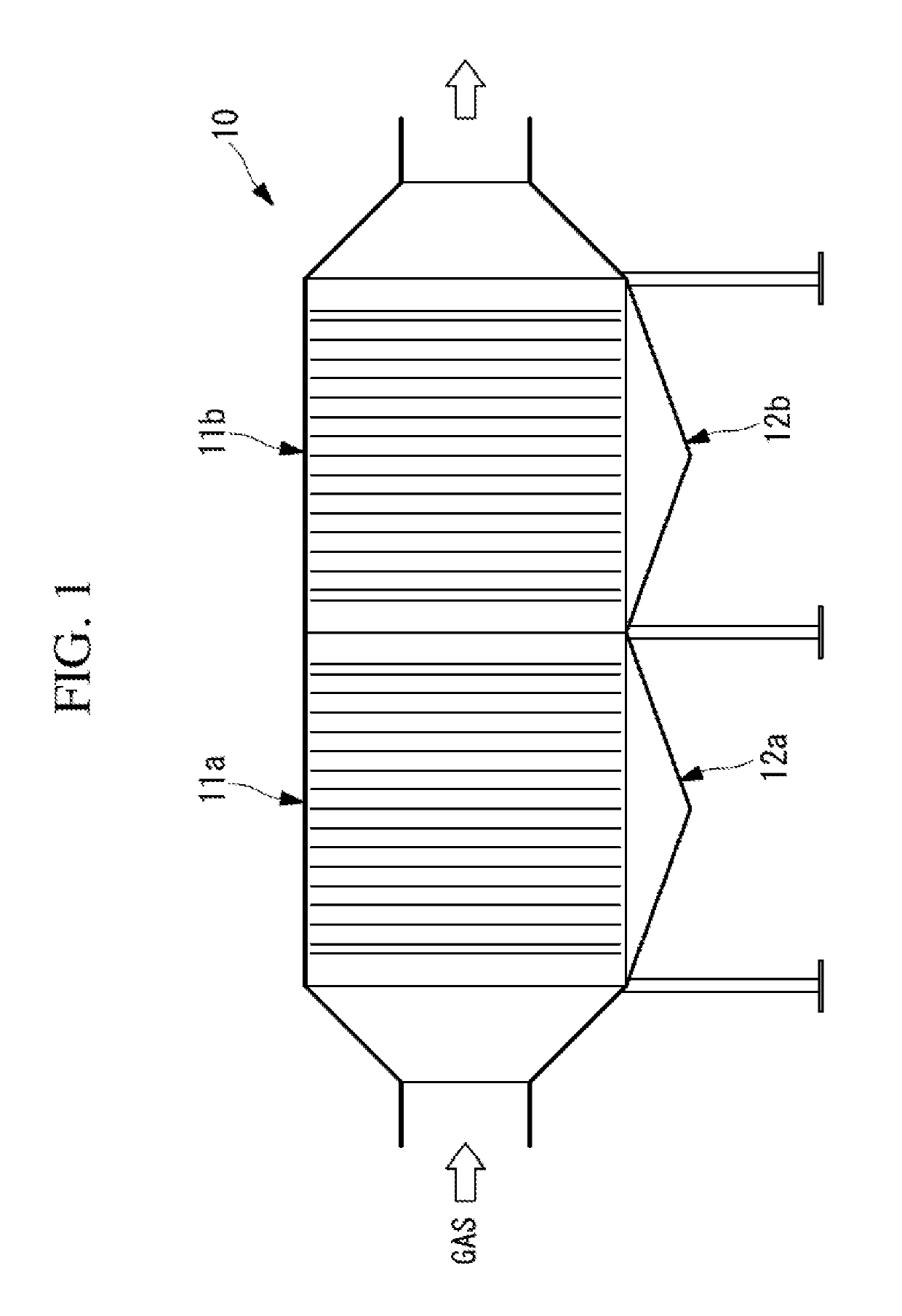

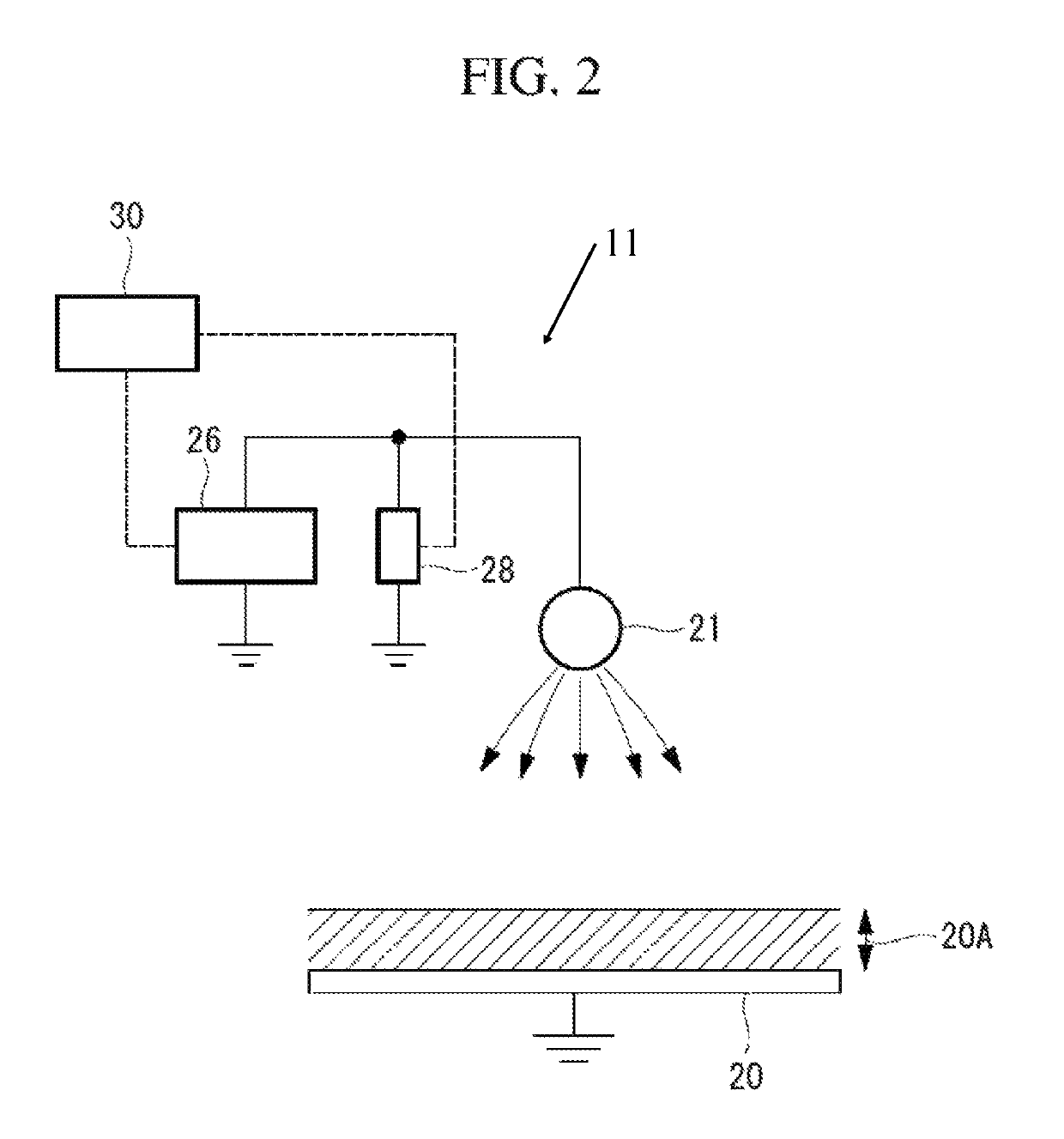

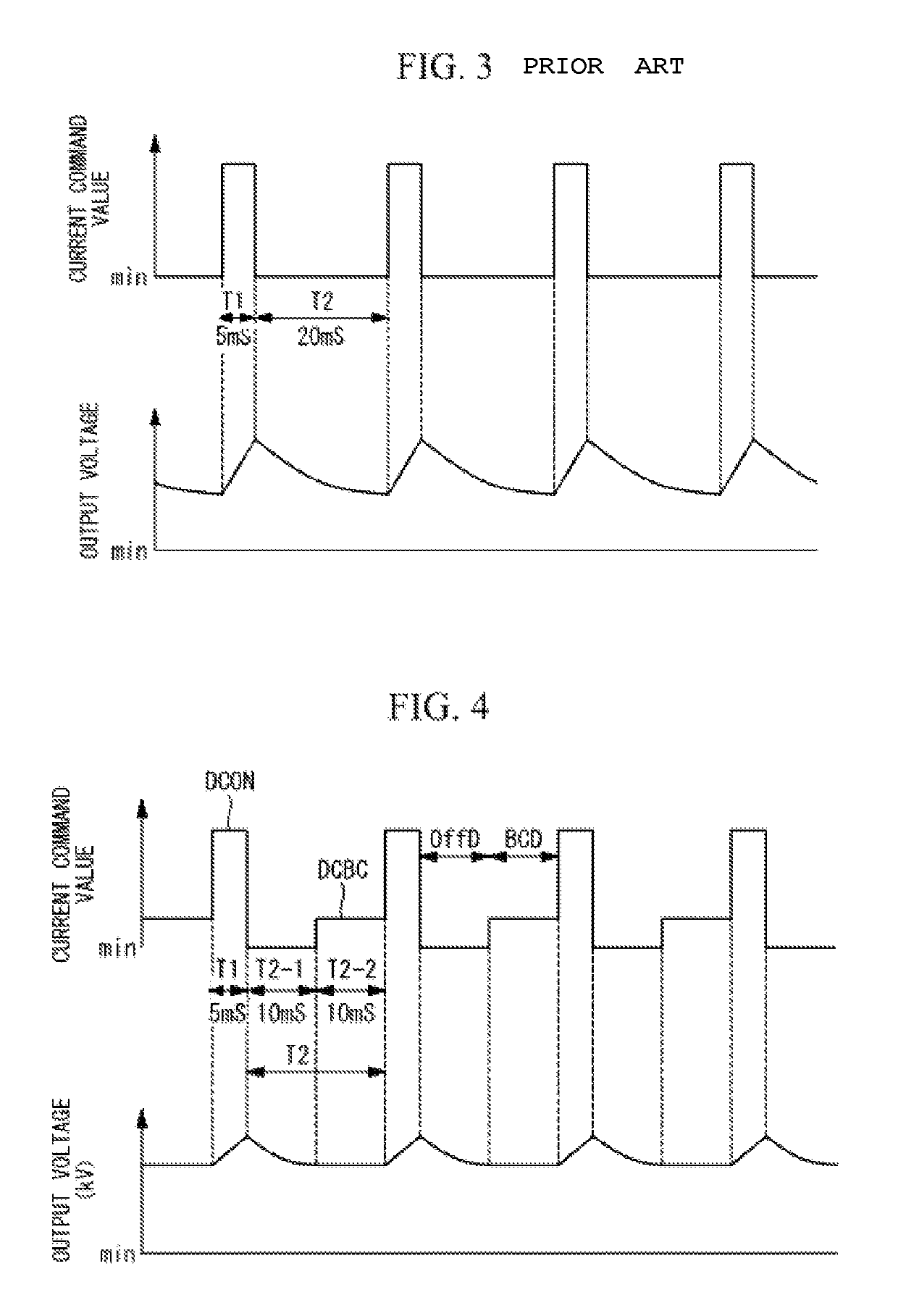

Electrostatic precipitator, charge control program for electrostatic precipitator, and charge control method for electrostatic precipitator

ActiveUS20170008008A1Excellent advantageous effects of suppressing occurrence of back coronaReduce dust collectionExternal electric electrostatic seperatorElectric supply techniquesCharge controlEngineering

In a charging time period T1, a dry electrostatic precipitator outputs DCON that is a current for charging a collection target object from a high voltage power supply. Subsequently, in a second period of time T2-2 after a first period of time T2-1 passes from a time that a charging pause time period T2 starts, the dry electrostatic precipitator outputs DCBC that is a current that is less than DCON and is greater than a current in the first period of time T2-1, from the high voltage power supply.

Owner:MITSUBISHI HITACHI POWER SYSTEMS ENVIRONMENTAL SOLUTIONS LTD

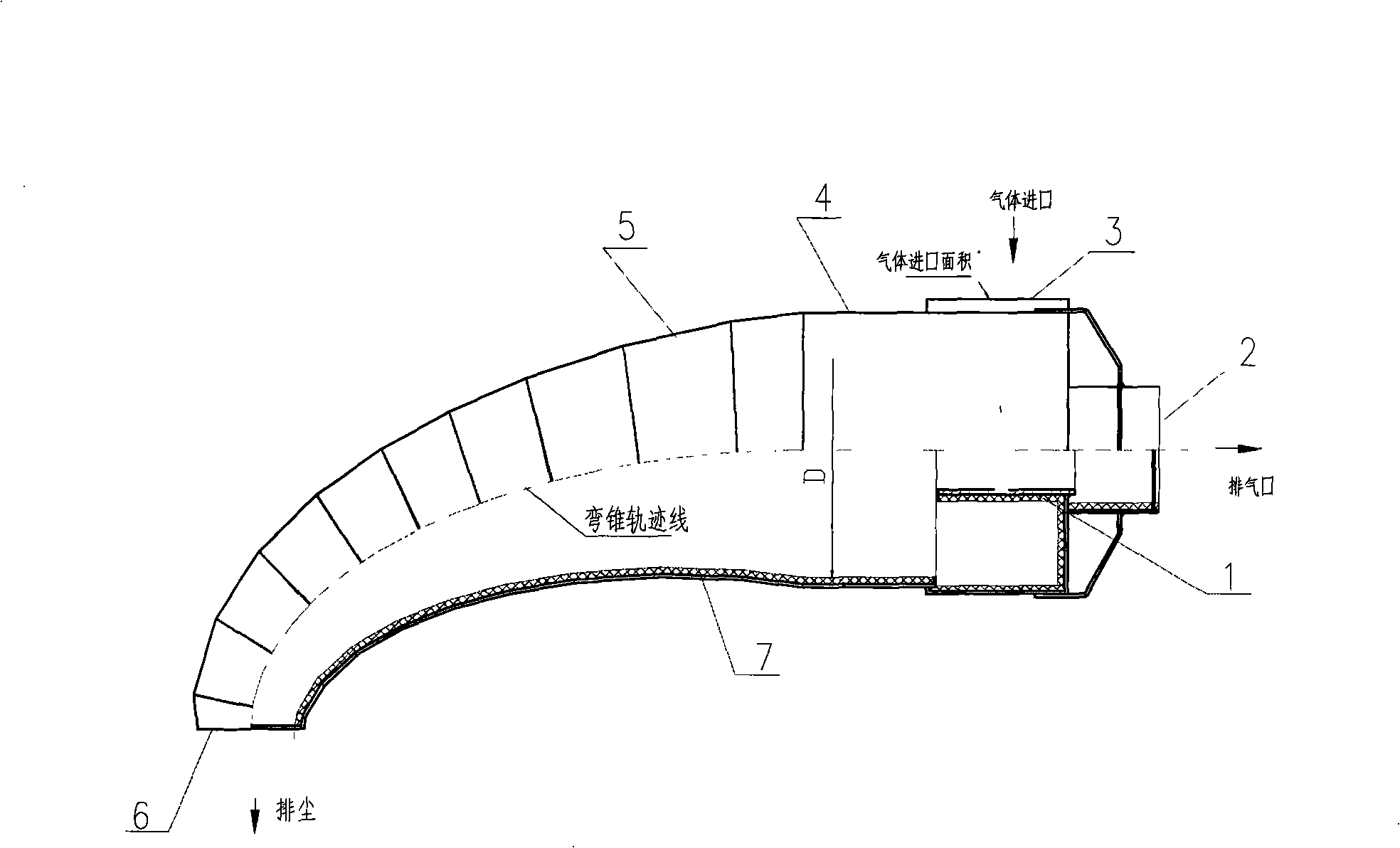

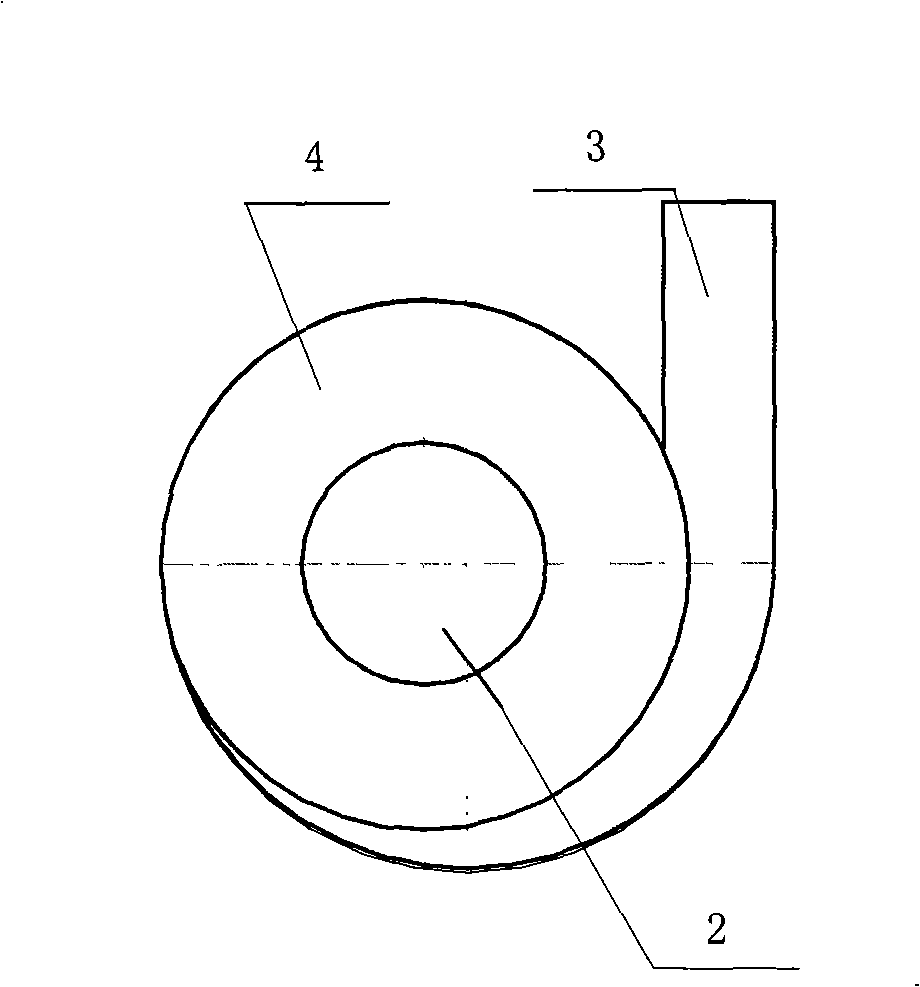

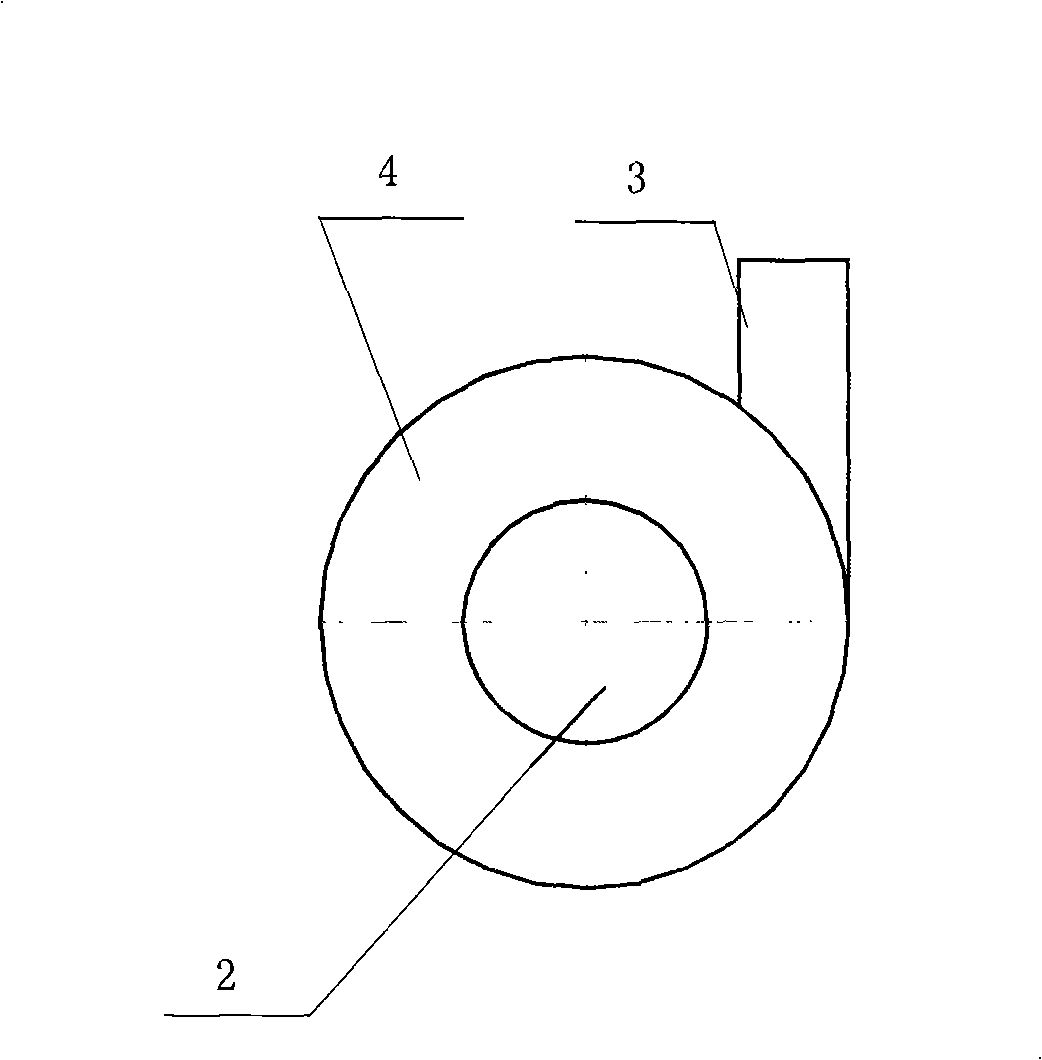

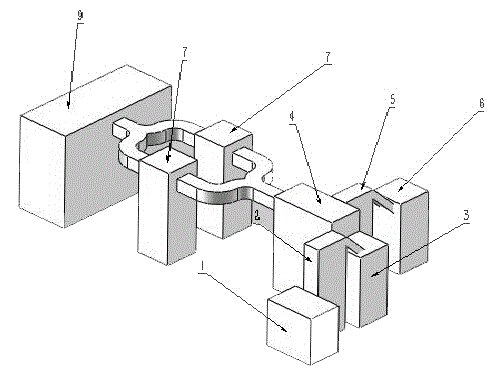

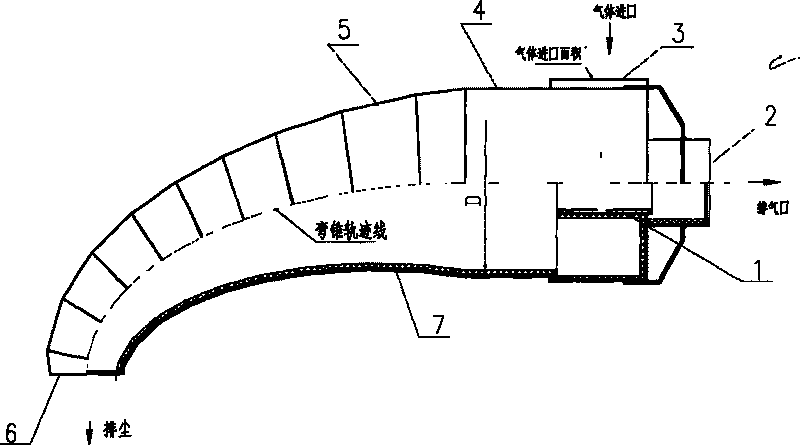

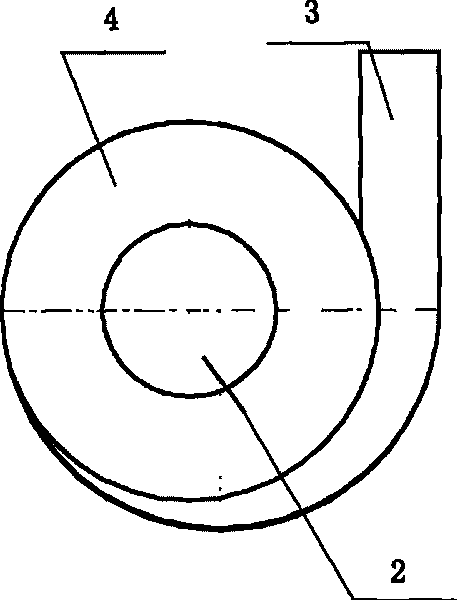

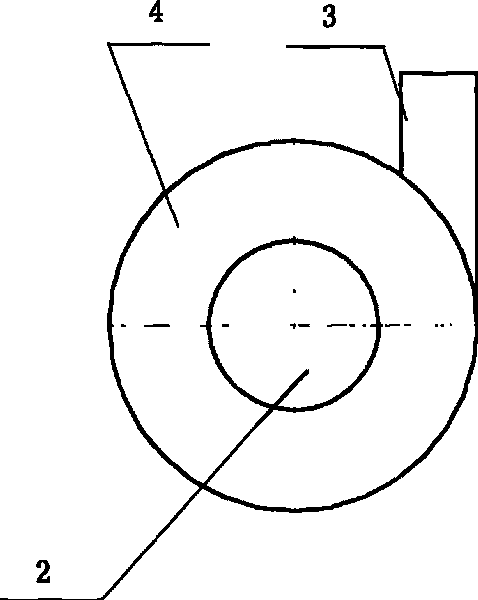

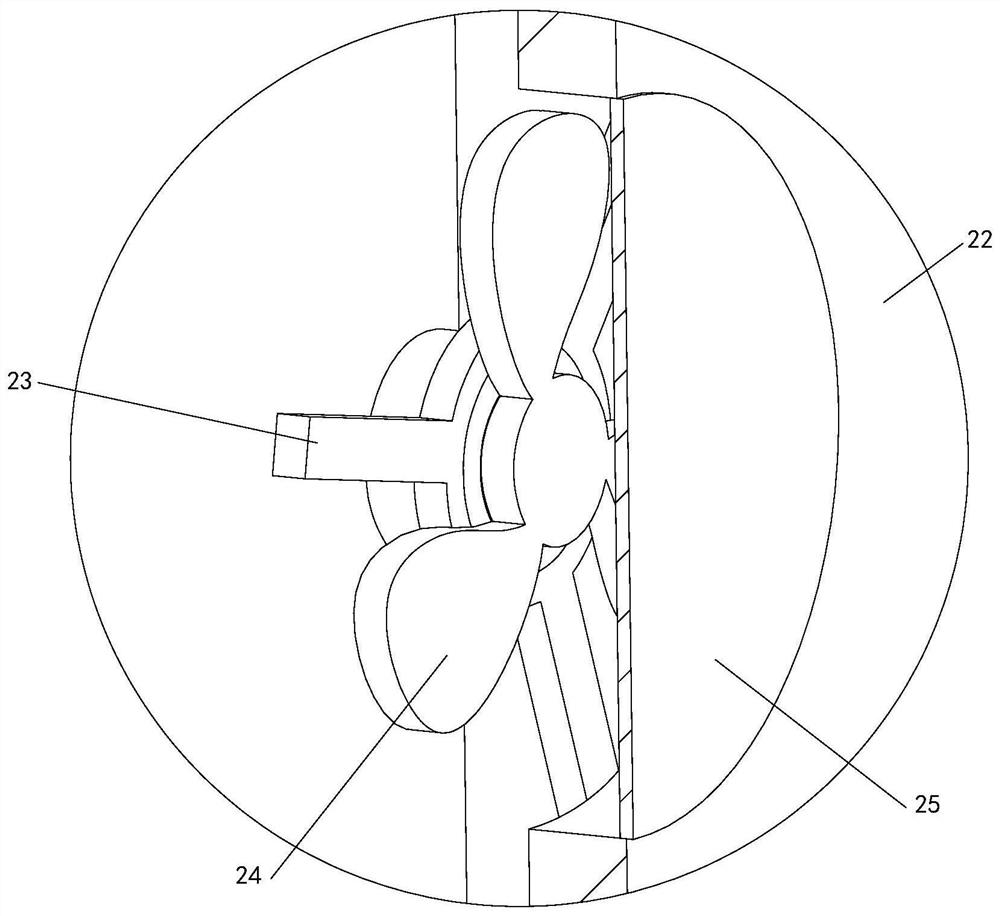

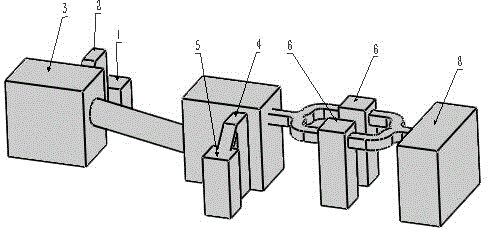

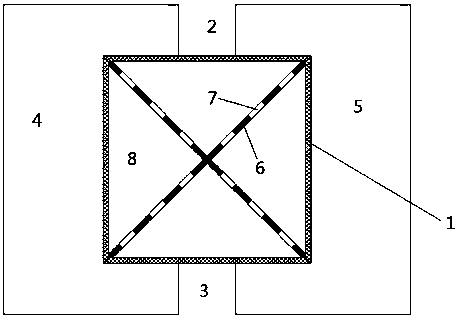

Cyclone separating device and uses thereof

The invention discloses a cyclone separator used for gas-solid or liquid-solid separation, comprising a gas riser, an air outlet, an air inlet, a straight cylinder section, a separation deposition cone section, a dust outlet, and a wearable layer. The cyclone separator is characterized in that the separation deposition cone section adopts a bent cone structure; the axis line track of the bent cone structure is an arc or an ellipse or other smooth transition curved lines. The cyclone separator is mainly used for the separation, recycling and exhaust of the wasted catalyst fine powders in the fourth-class cyclone separation system of a petroleum chemical fluid catalytic cracking device. The cyclone separator with the bent cone structure has installation height which is only one third of the installation height of a vertical cyclone separator, and is applicable to the design and reconstruction of devices with equipment installation space to be restricted; meanwhile, the bent-cone typed cyclone separator has simple structure, large wind disposal quantity and high efficiency; furthermore, as the liner material with high wearability is adopted, the cyclone separator of the invention can be used under high temperature for a long time.

Owner:SINOPEC ENG +1

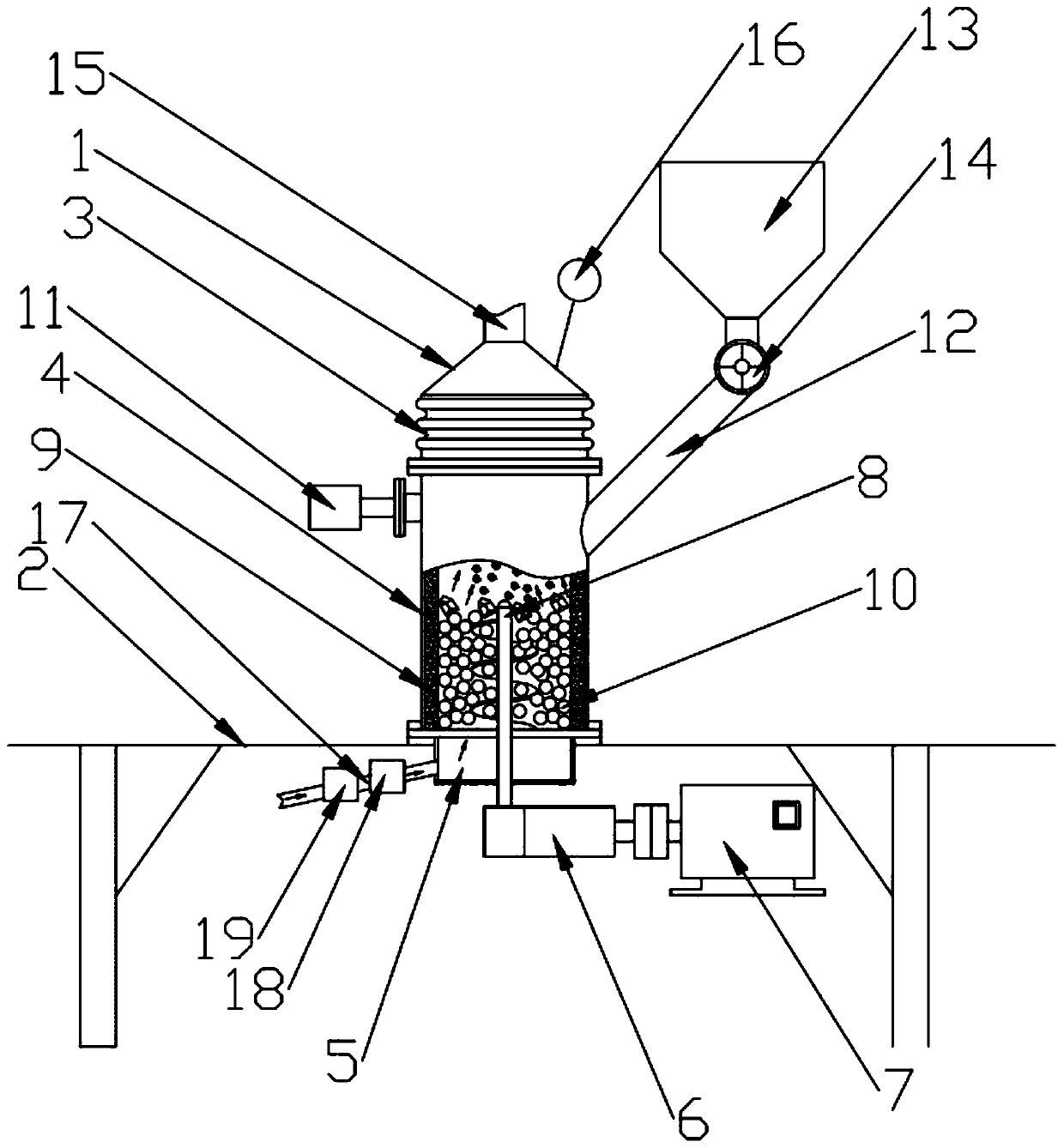

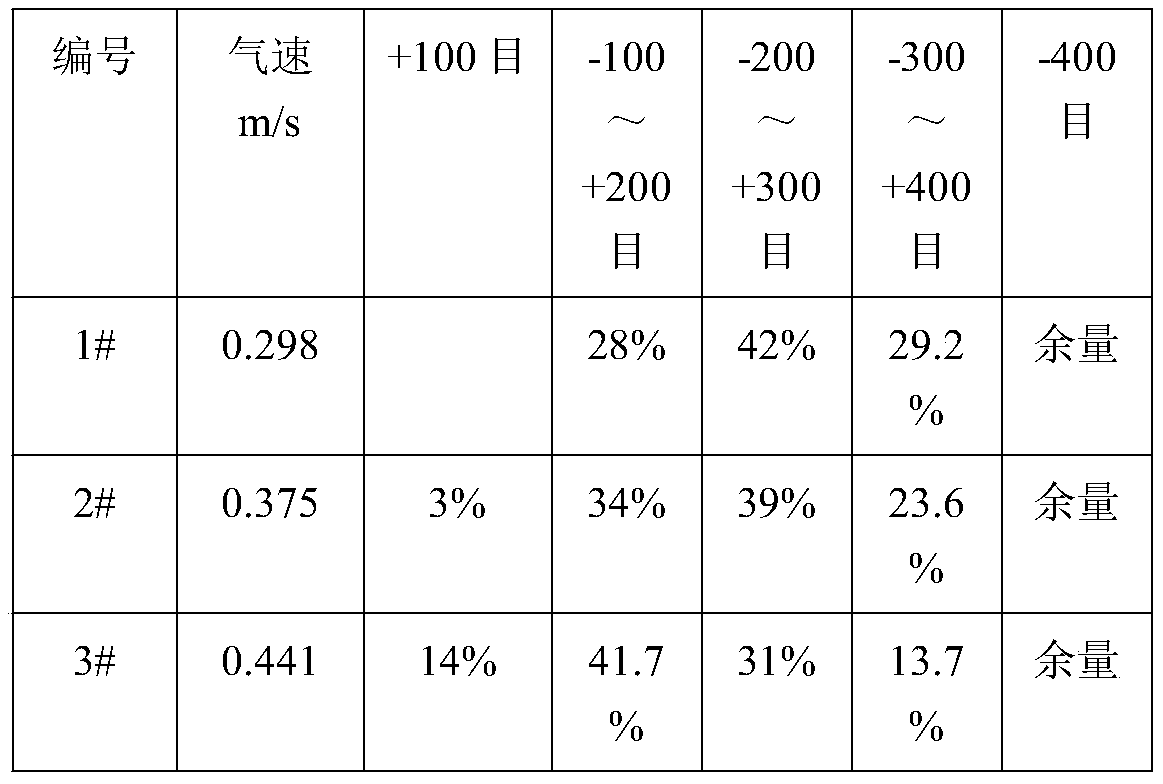

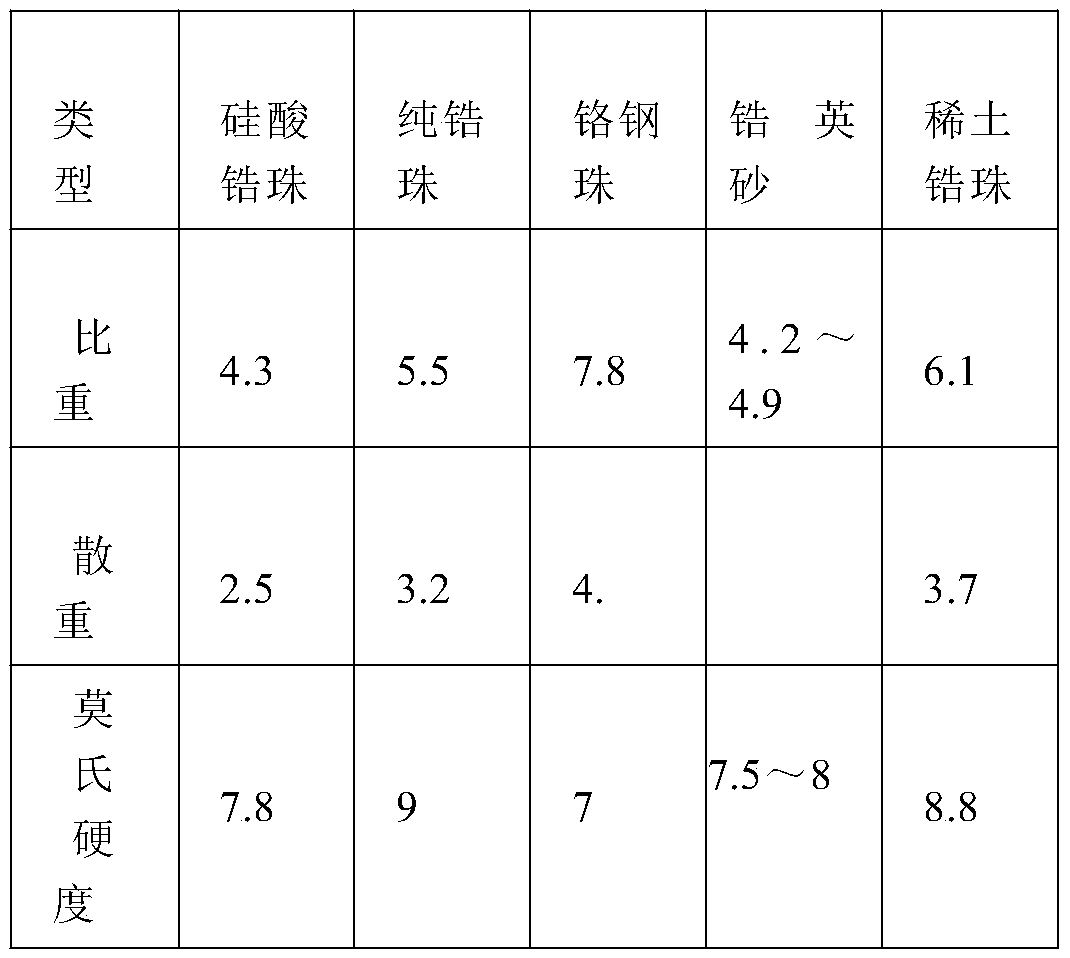

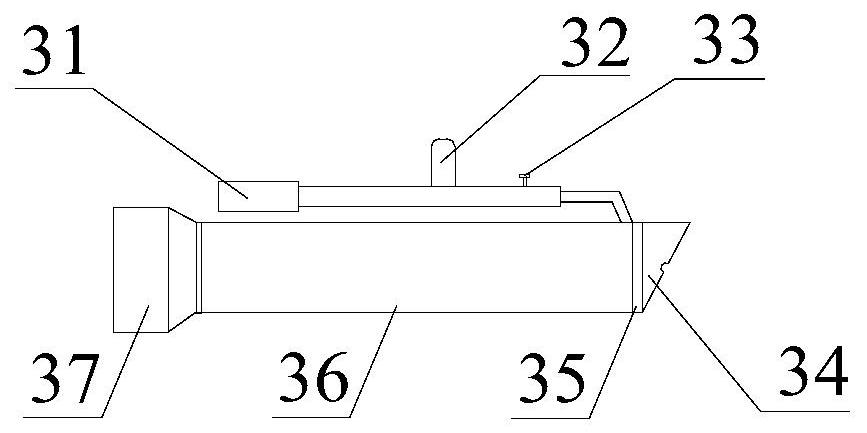

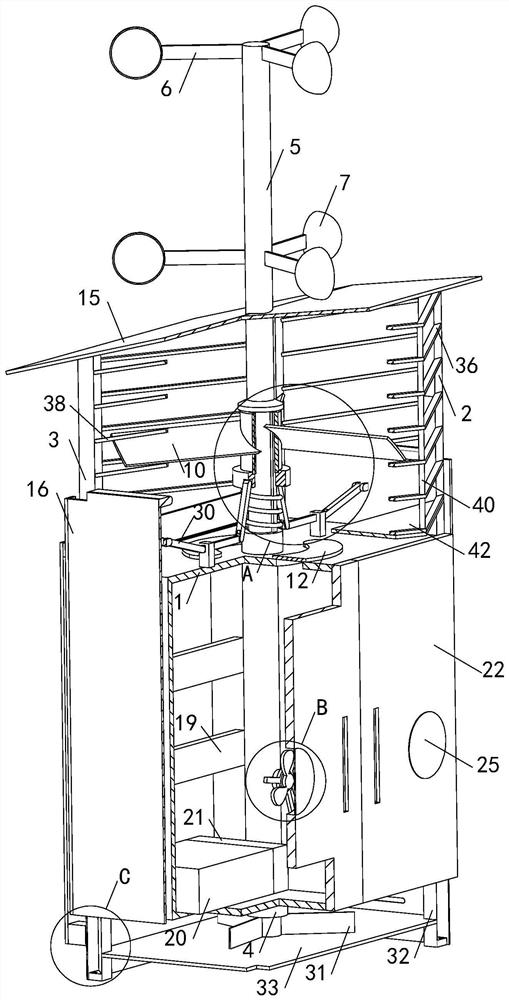

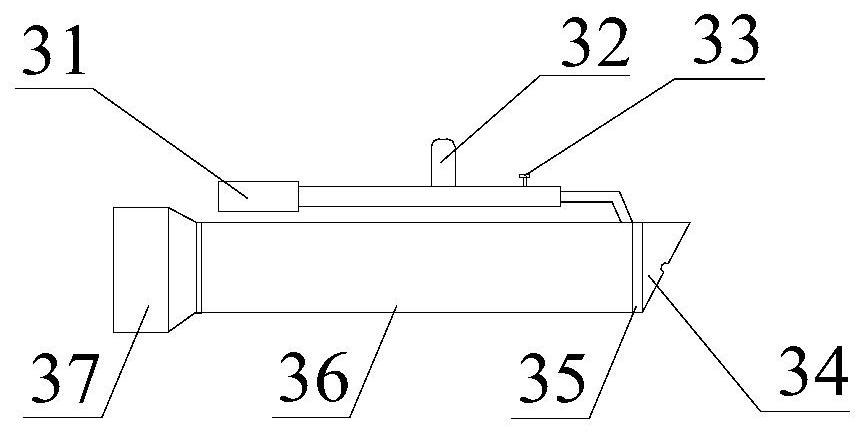

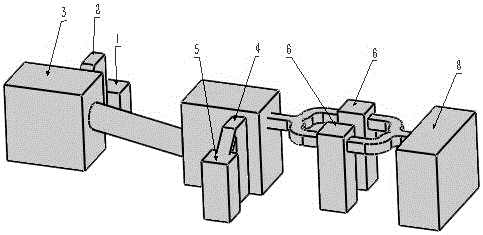

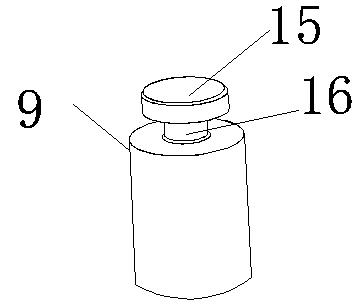

Vertical winnowing pulverizer for zirconium fluidizing chlorination industry

PendingCN110193406AThere will be no "layering" phenomenonProcess safetyGrain treatmentsProduction lineBiochemical engineering

The invention discloses a vertical winnowing pulverizer for the zirconium fluidizing chlorination industry. The pulverizer is characterized by comprising a pulverizer body, a rack and a PLC, wherein the pulverizer body is installed on the rack, the pulverizer body comprises a top adjusting section and a bottom fixing section, the bottom of the fixing section is connected with an air distributor, aspeed reducer is arranged below the pulverizer body, the speed reducer is electrically connected with a motor, a stirrer stretching into the fixing section is arranged at the top of the speed reducer, a zirconium lining plate is arranged at the inner wall of the fixing section, a zirconium oxide ball is arranged inside the fixing section, a level meter is arranged at one side of the fixing section, and a feeding pipe is arranged at the other side of the fixing section. The pulverizer has the advantages that the equipment structure is simple, the floor area is small, maintenance is easy, investment is small, little vibration is caused, noise is low, a finished product collecting bin can replace a fluidizing chlorination furnace storage drying bin and can be marshaled with a chlorination production line, the production line main control DCS can be connected with the pulverizer, quantitive and continuous pulverizing is performed, and production and management are convenient.

Owner:锦州旭日新材料科技有限公司

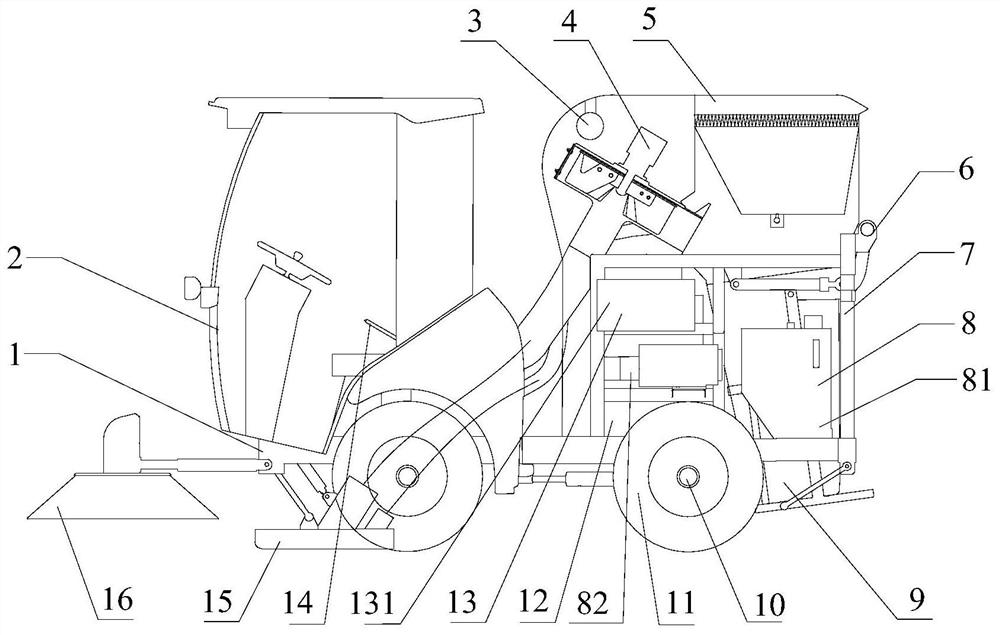

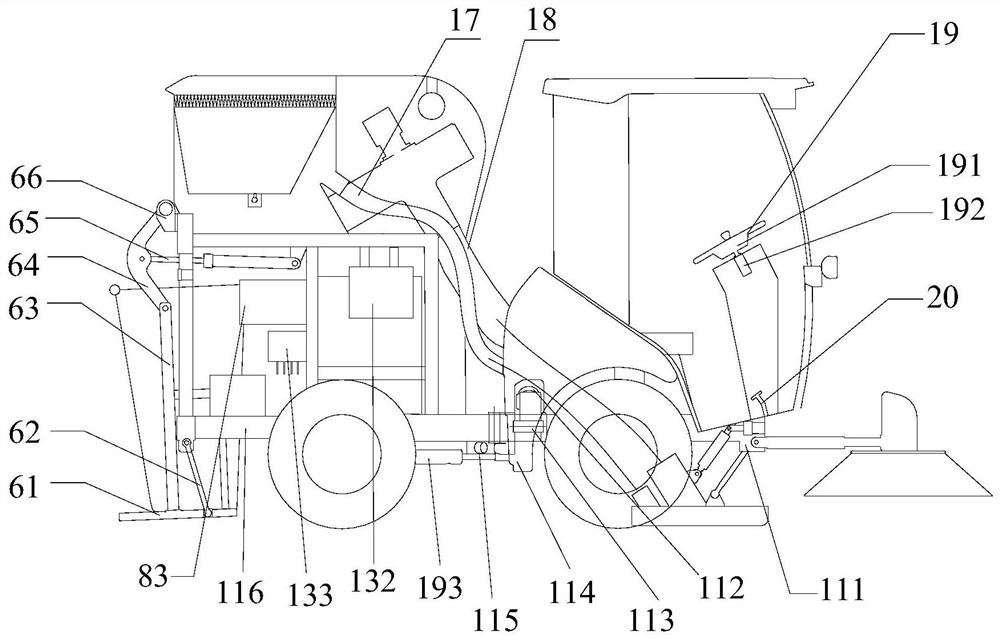

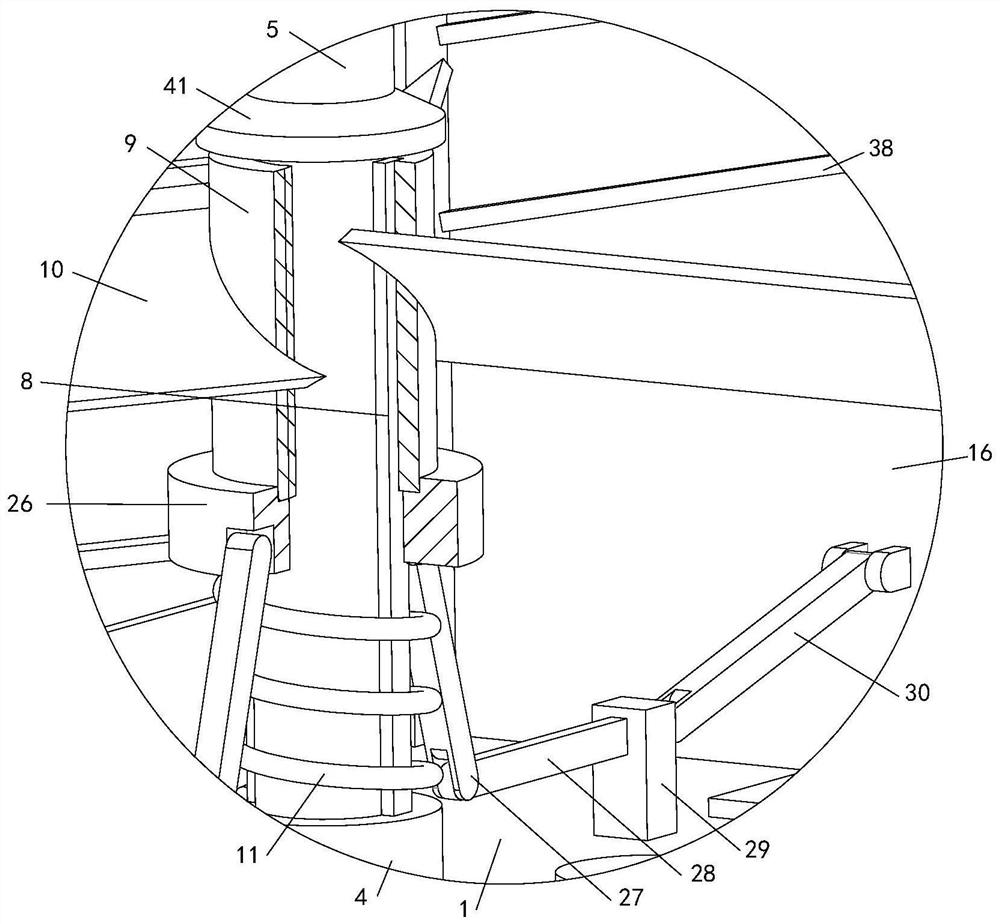

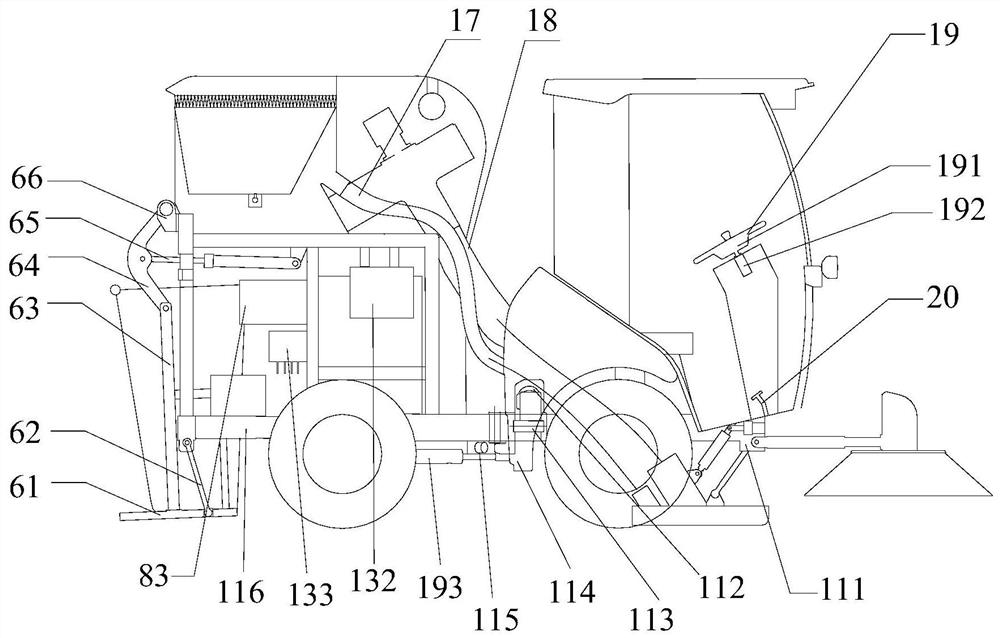

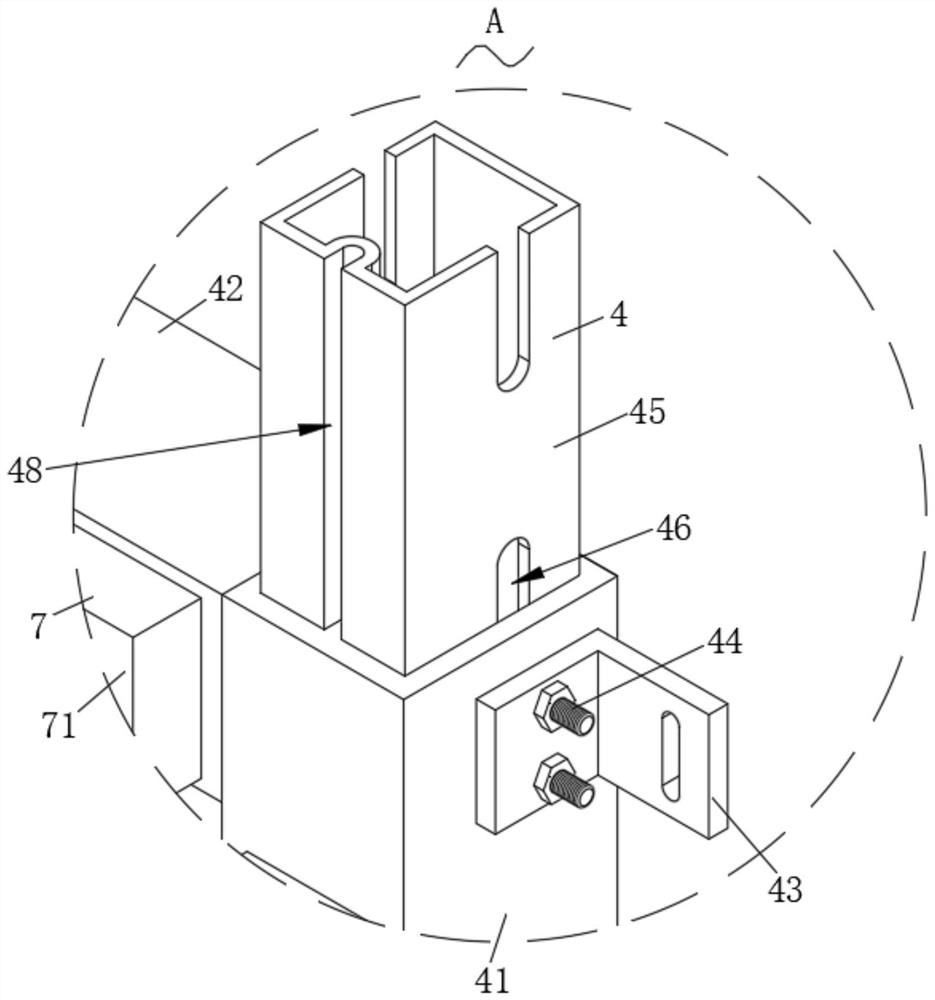

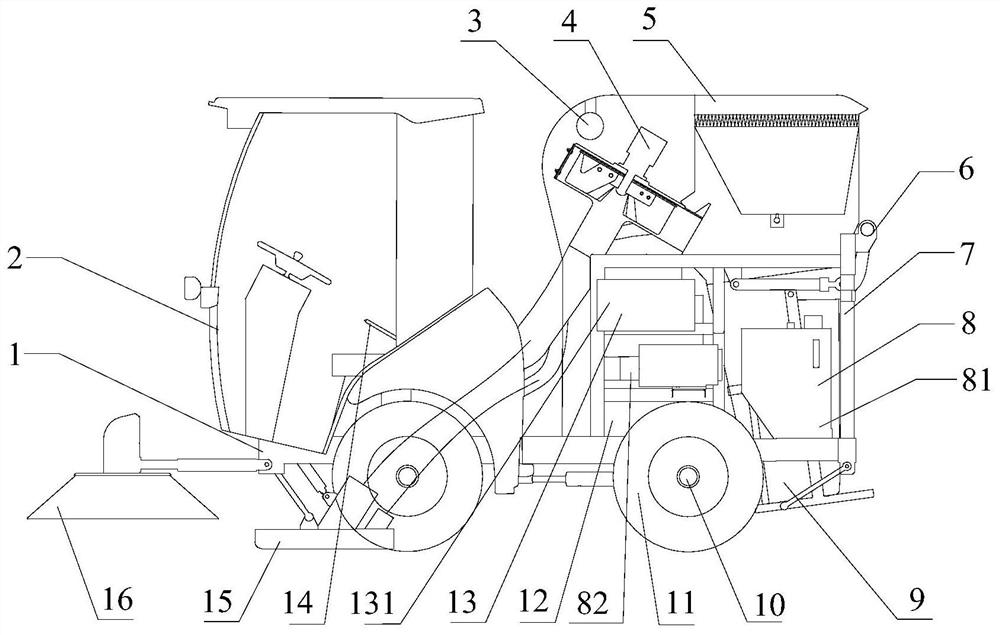

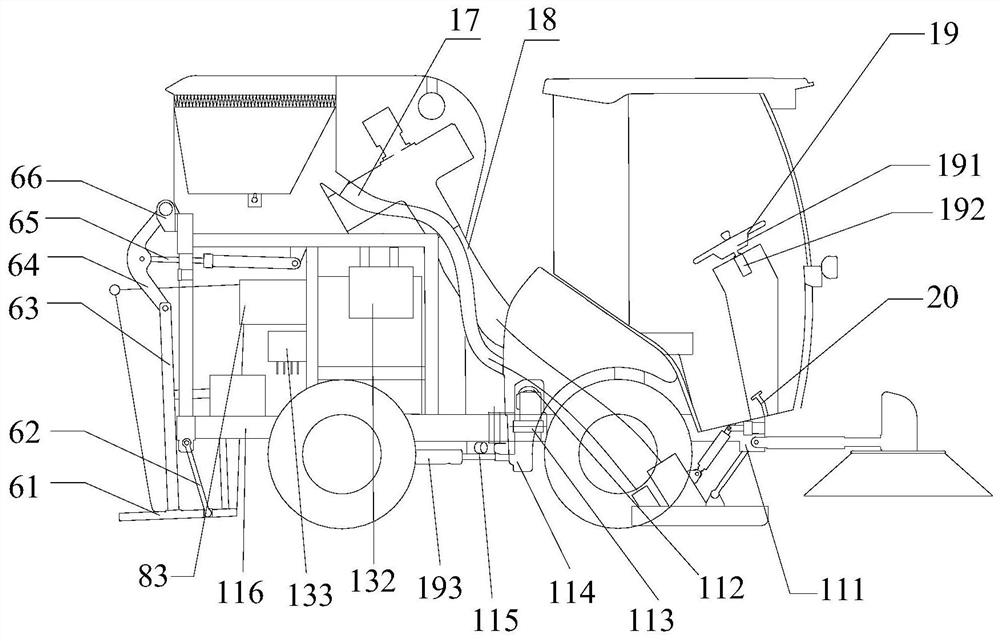

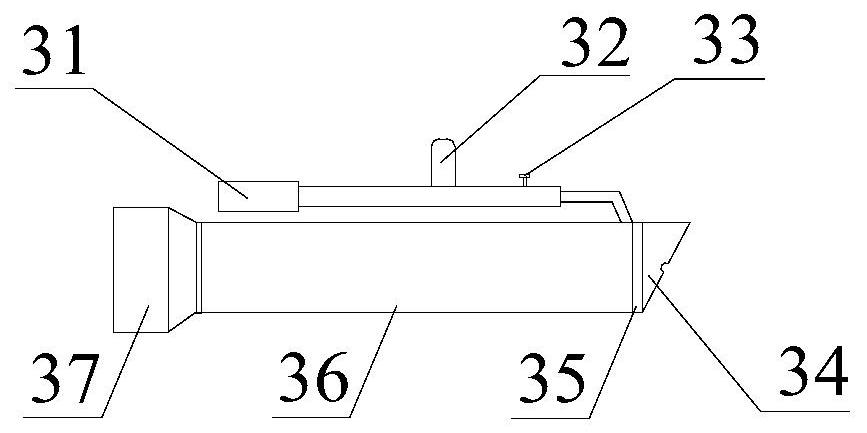

Dust removal system and dry road sweeper with same

ActiveCN112012146AReduce dust collectionLong cleaning intervalsHuman health protectionUsing liquid separation agentRoad sweeperWater vapor

The invention discloses a dust removal system and a dry road sweeper with the same. A flow guide cover is arranged at an air inlet; an airflow and garbage are directly guided into a garbage can, mostof the garbage settles at the bottom of the garbage can under the action of gravity, part of light garbage, water vapor and dust can ascend from the garbage can under the action of the airflow, the light garbage is blocked through a filter screen, and only the airflow mingled with the water vapor and the dust is allowed to enter the dust removal box body. The airflow mingled with water vapor and dust enters the dust removal box body; an inertia water removal device captures water vapor and most of dust; a second dust removal device only needs to remove a small part of dust mixed in the airflow, so that the dust removal amount of the second dust removal device is greatly reduced, the dust removal interval time of the second dust removal device is longer, the effective working time is prolonged, and the sweeping efficiency is improved; the inertia water removal device and the second dust removal device are matched for dust removal operation, and the overall dust removal effect is better.

Owner:ZOOMLION ENVIRONMENTAL IND CO LTD

Stainless steel slag sorting device and stainless steel slag sorting method

The invention relates to the technical field of steel slag treatment in metallurgical industry, and discloses a stainless steel slag sorting device and a stainless steel slag sorting method. The stainless steel slag sorting device comprises a material hopper, a bar screen, a bucket elevator, a powder sorter, a cyclone dust collector and a bag-type dust collector, wherein the powder sorter is externally connected with an air blower; a granule outlet is formed in the bottom end of the powder sorter; a powder outlet is formed in the upper part of a side wall opposite to the material inlet of the powder sorter. According to the stainless steel slag sorting device and the stainless steel slag sorting method, after stainless steel slag raw materials are screened primarily, stainless steel slag is sorted by the powder sorter in a micro-negative-pressure work environment, so that the beneficiation of the granules which contain metal materials and have larger granule size is realized favorably, the powder with smaller granule size is collected by the cyclone dust collector, and dust can be prevented from being exhausted into atmosphere by the bag-type dust collector. By using the stainless steel slag sorting device and the stainless steel slag sorting method, the abrasion of equipment caused by steel slag is reduced; the service life of the equipment is prolonged; the production cost is reduced; meanwhile, the water using amount and the water treatment cost of wet treatment are also reduced; energy is saved; emission is reduced.

Owner:甘肃润源环境资源科技有限公司

Graphene modified antistatic polypropylene composite material and preparation method thereof

InactiveCN111484681AImprove antistatic performanceImprove cleanlinessPolypropylene compositesGraphite

The invention discloses a graphene modified antistatic polypropylene composite material and a preparation method thereof. The graphene modified antistatic polypropylene composite material is composedof the following raw materials in percentage by mass: 54-76% of polypropylene, 18-28% of an inorganic filler, 0.1-1.5% of graphene, 5-15% of a toughening agent, 0.2-1.5% of a coupling agent, 0.3-0.9%of an antioxidant, and 0.2-1% of a nucleating agent. The graphene modified antistatic polypropylene composite material has the advantages that after graphene is used for modifying the polypropylene composite material, the mechanical property of the polypropylene composite material is improved, meanwhile, the antistatic effect of polypropylene can be remarkably improved, the dust collection degreeis reduced, a workpiece is kept clean and attractive, the preparation process is simple, the cost is relatively low, and large-scale industrial production is easy to carry out.

Owner:四川鑫达企业集团有限公司

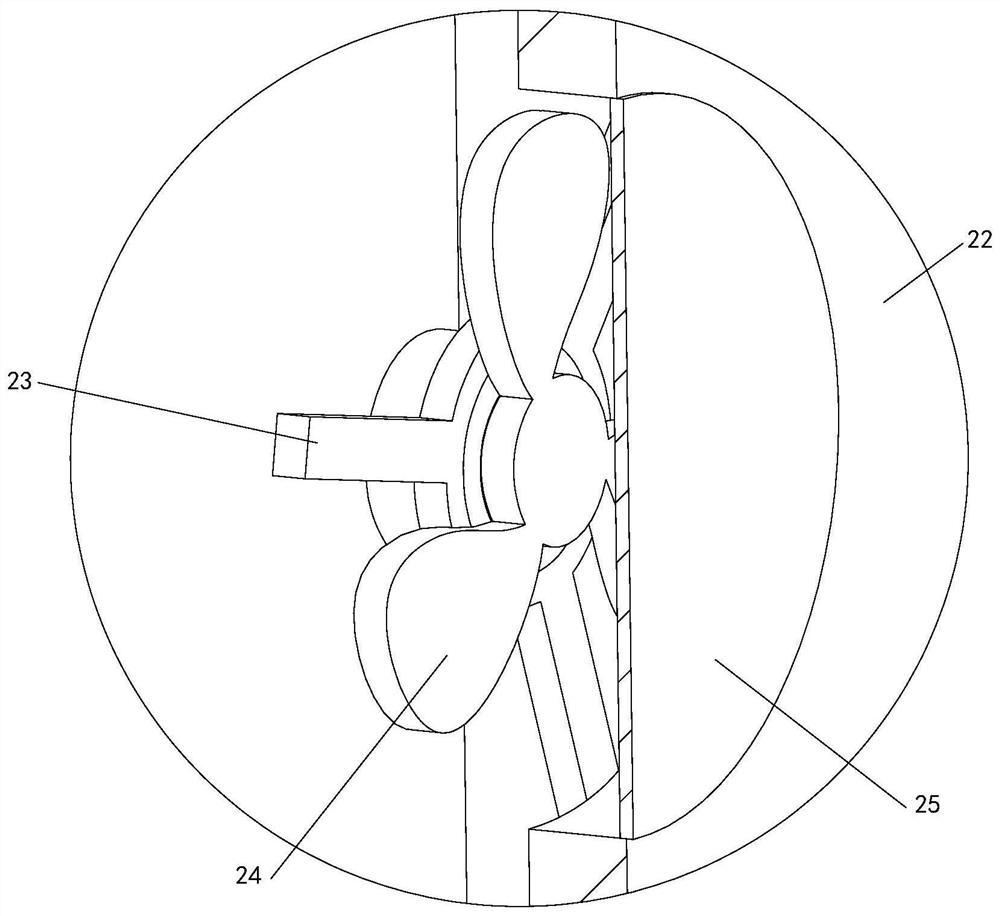

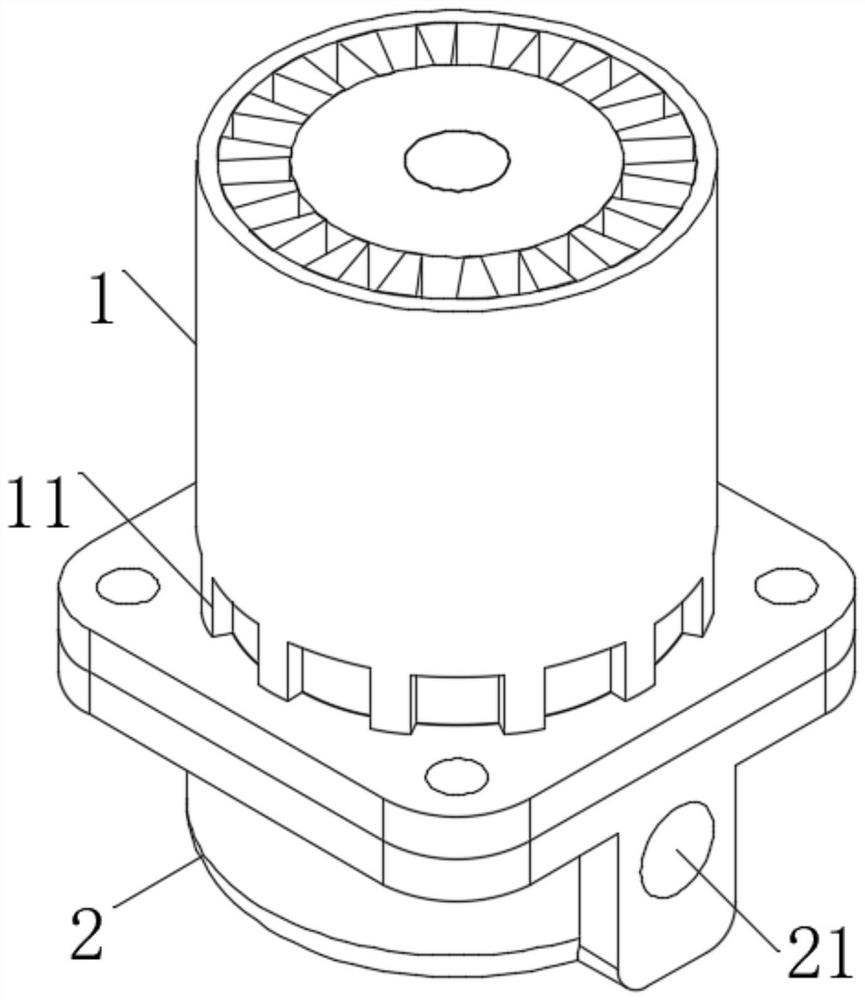

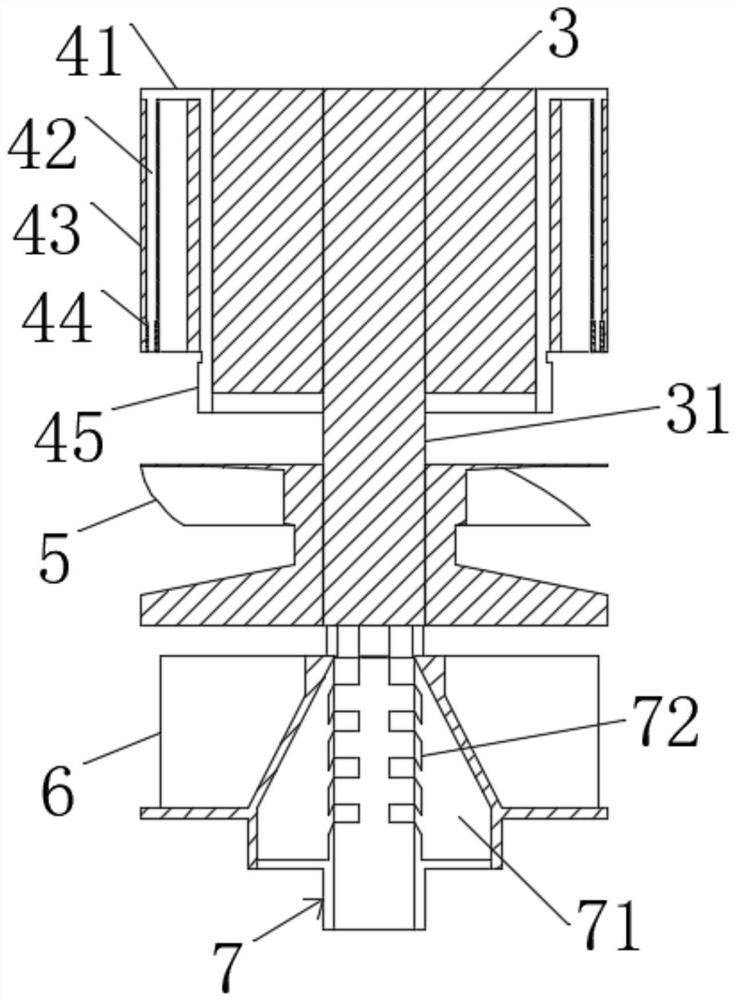

An energy-saving heat-dissipating high-voltage cabinet

ActiveCN112490911BIncrease the installation areaEasy to drivePV power plantsSubstation/switching arrangement cooling/ventilationClassical mechanicsThrust bearing

The invention relates to the technical field of high-voltage cabinets, in particular to an energy-saving and heat-dissipating high-voltage cabinet, comprising a cabinet body, two long pillars and two short pillars, wherein the two long pillars and the two short pillars are both connected to the cabinet body, and the cabinet body passes through The two thrust bearings are connected with a vertical shaft, and the vertical shaft is connected with a plurality of driving sleeves and a plurality of driving strips. The vertical shaft is connected with a plurality of fan blades through an installation ring, and the installation ring is connected with a traction mechanism. The traction mechanism is close to the two thrust bearings. A tension spring is connected between the thrust bearings on the upper side, an annular filter dust-proof plate and a back plate are installed in the cabinet, two long and two short columns are connected with an inclined frame, and the long and short columns are connected by a wing bracket. The fan-shaped bracket, the wing bracket is connected with the traction mechanism, the solar panel is installed on the back plate, the inclined frame, the wing bracket and the fan-shaped bracket, the battery and the generator are installed in the cabinet, and the cabinet is connected with two installation door mechanisms, which are relatively Energy saving, clean use, stable heat dissipation, and more practical.

Owner:孔祥富

Bag filter fabric and production method therefor

InactiveUS20200164295A1Improve collection effectLower overall pressure dropDispersed particle filtrationLayered productsSingle fibreNonwoven fabric

The invention addresses the problem of providing a filter fabric for a bag filter, which has excellent collection performance and low pressure drop and is resistant to a decrease in dust collection performance due to abrasion or cracking, and also a method for producing the same. Means for resolution is a filter fabric for a bag filter in which a nonwoven fabric A including short fibers a having a single-fiber fineness of 0.3 to 0.9 dtex, a base fabric, and a nonwoven fabric B including short fibers b having a single-fiber fineness of 0.3 to 4.0 dtex are laminated in this order.

Owner:TEIJIN FRONTIER CO LTD

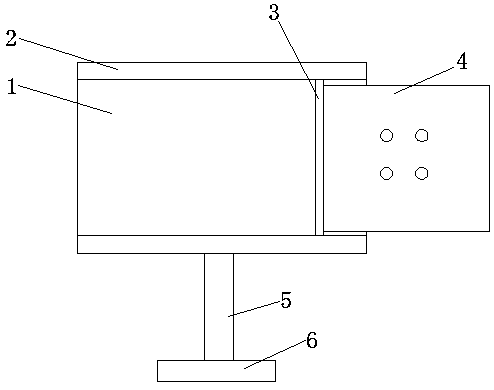

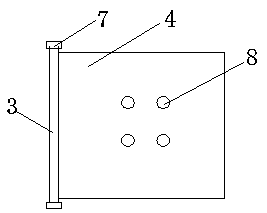

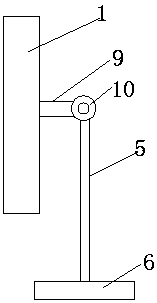

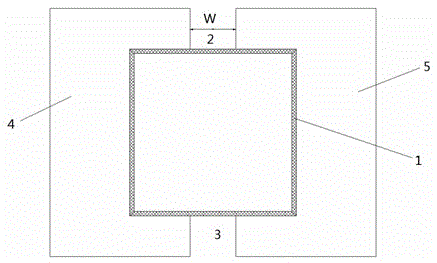

Sliding computer display screen

InactiveCN107589790AReduce dust collectionExtended service lifeDigital data processing detailsEngineeringComputer engineering

Owner:刘勇勇

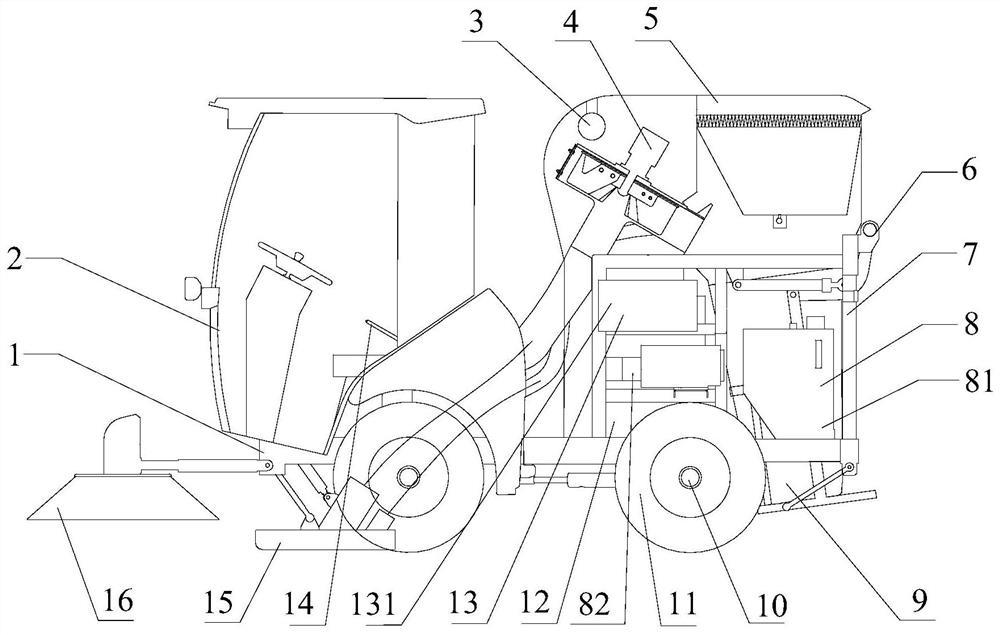

Dry Sweeper

ActiveCN112012145BImprove pick-up efficiencyExtended working hoursRoad cleaningRoad sweeperWater vapor

The invention discloses a dry road sweeper. In the dry road sweeper of the present invention, after the fan starts to work, the garbage, water droplets and dust on the road surface are sucked into the fan, and the dust removal system first guides the airflow into the garbage can to settle the garbage, and then performs water and dust removal on the airflow to remove dust. The water vapor and most of the dust mixed in the air flow are eliminated, and the dust removal capacity of the subsequent dust removal device is reduced. Part of the airflow after the water and dust removal treatment is filtered by the dust removal device and discharged out of the car, and the other part of the air flow is transported to the suction nozzle through the back blowing pipe for back blowing, which reduces the pressure loss of the dust removal device and further reduces its dust removal capacity. Ensuring that it has good continuous dust removal ability prolongs the working time of the dry sweeper. Moreover, with the improvement of the continuous dust removal ability of the dust removal device and the back-blowing recycling of the airflow, the dust removal ability of the dry road sweeper is greatly improved, and there is no need to spray water to reduce dust, and water-free operation can be realized, especially suitable for winter Do your homework.

Owner:ZOOMLION ENVIRONMENTAL IND CO LTD

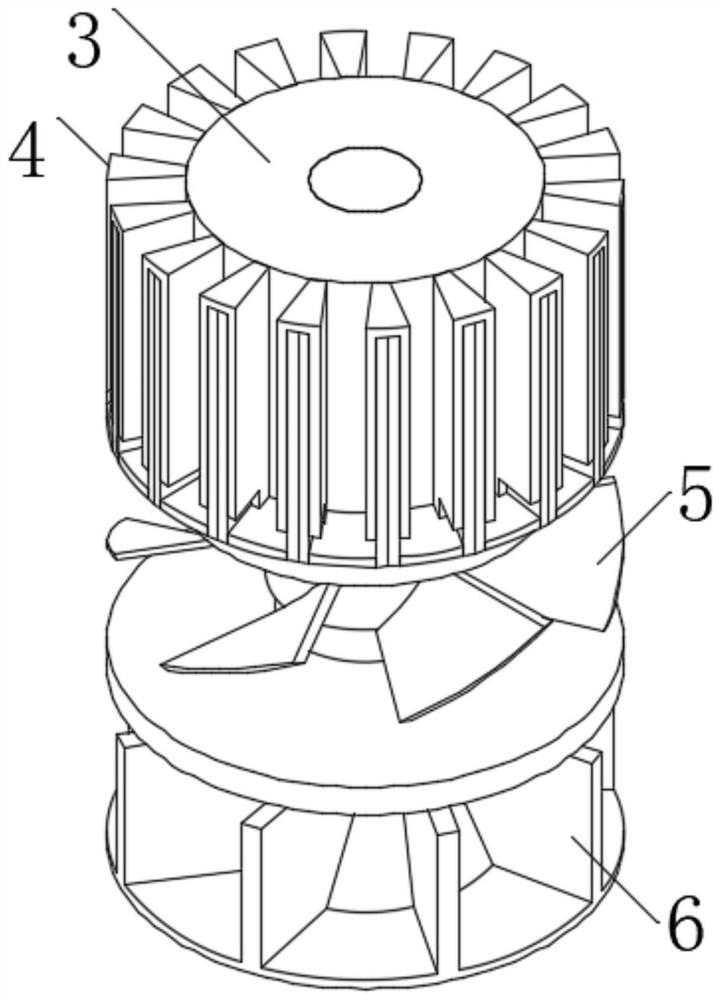

Energy-saving heat dissipation type high-pressure hot water circulating pump

PendingCN114263618AAchieve closureExtended pathSpecific fluid pumpsPump componentsImpellerElectric machine

The invention discloses an energy-saving heat dissipation type high-pressure hot water circulating pump, and relates to the technical field of circulating pumps. The device comprises an outer shell and a bottom shell, the outer shell is communicated with the bottom shell, a heat dissipation part is installed in the outer shell, a motor is installed in the heat dissipation part, a first impeller and a second impeller are installed on a shaft body of the motor, the first impeller is located in the outer shell, the second impeller is located in the bottom shell, and exhaust holes are formed in the side face of the outer shell. A liquid inlet hole is formed in the side face of the bottom shell. The rotating shaft body drives the first impeller and the second impeller to rotate, the first blade arranged in the first impeller exhausts air in the first cavity through the exhaust hole, and external air enters the first cavity through the heat dissipation part, so that heat dissipation of the motor and the shaft body is completed.

Owner:江苏维尔特泵业有限公司

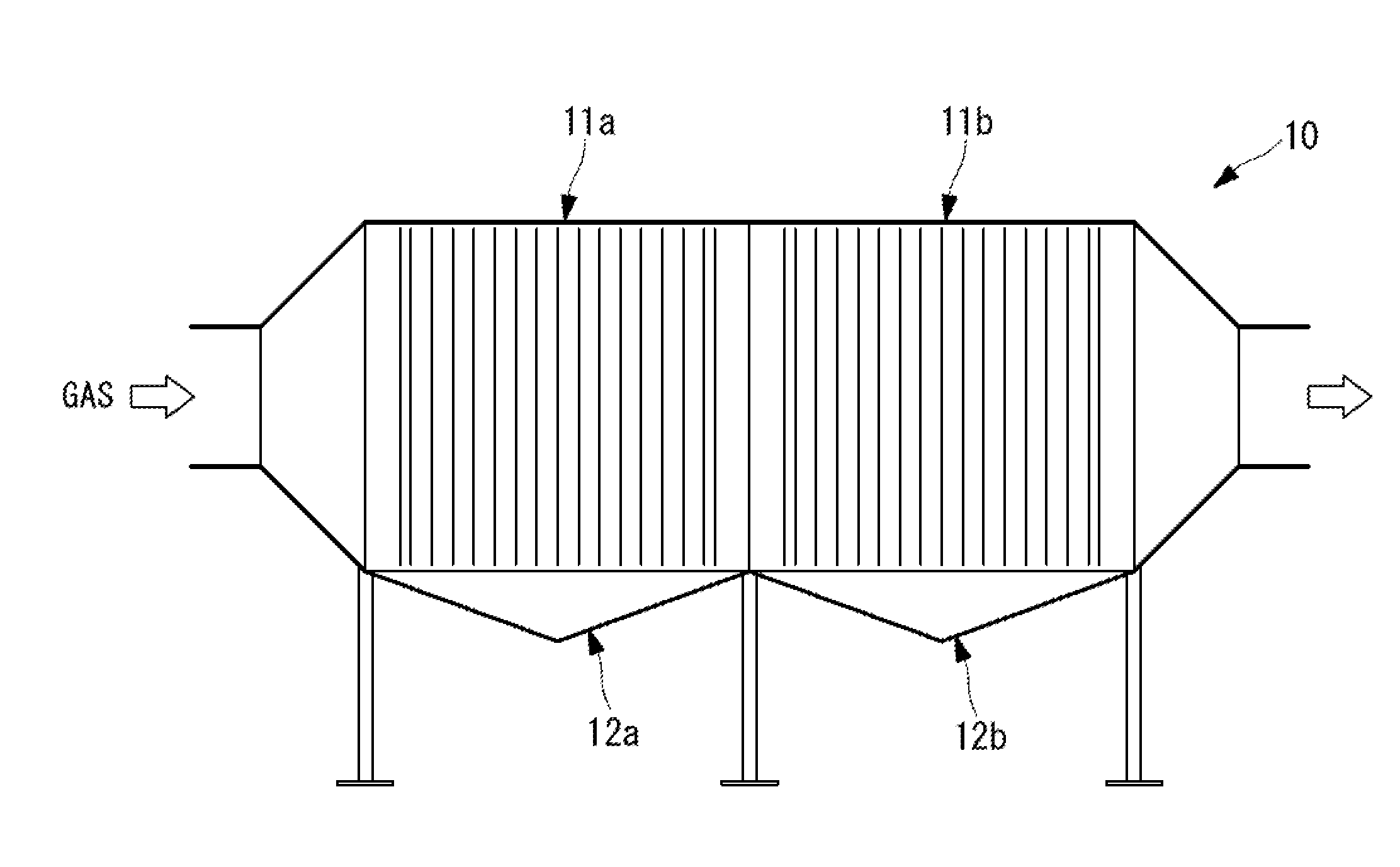

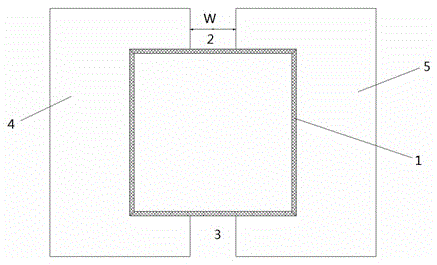

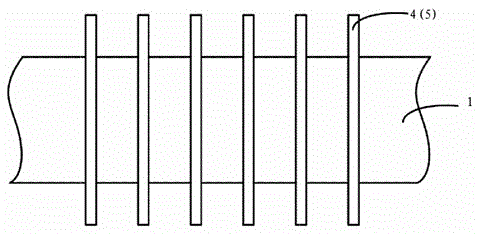

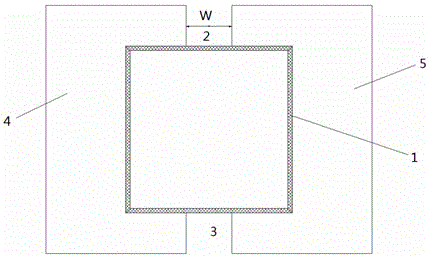

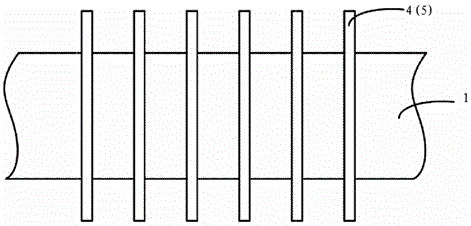

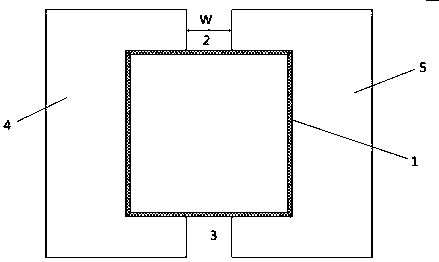

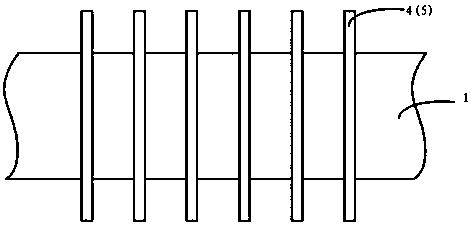

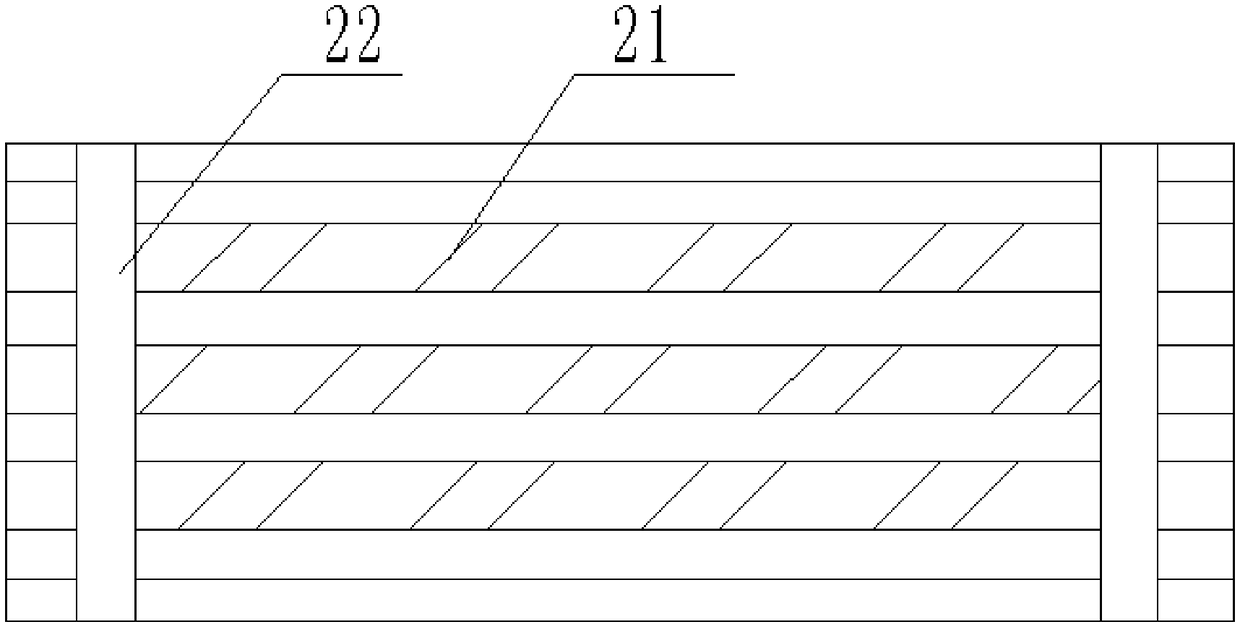

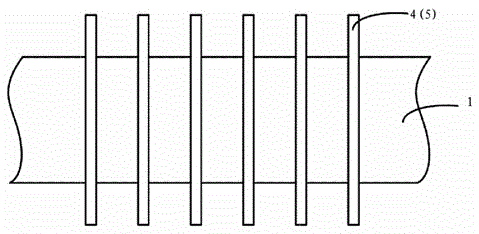

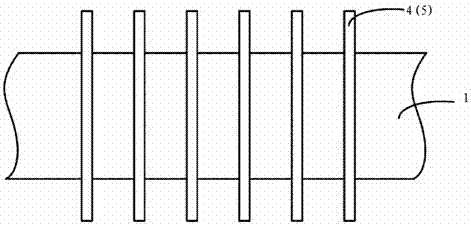

H-shaped heat exchange pipe

ActiveCN105674784AReduce dust collectionImprove heat transfer efficiencyTubular elementsEngineeringMechanical engineering

The invention provides an H-shaped heat exchange pipe which comprises a base pipe and multiple sets of fins. The multiple sets of fins are arranged on the base pipe at intervals in the axis direction of the base pipe, and each set of fins is parallel to the cross section of the base pipe. Each set of fins includes two fins, wherein the two fins are symmetric about the face where the axis of the base pipe is located. The cross section of the base pipe is rectangular. The fins are rectangular. A first opening and a second opening are formed between every two fins, wherein the first opening and the second opening are symmetric about the face where the axis of the base pipe is located. A finned pipe is provided so that the function of heat transfer strengthening can be met, and meanwhile dust accumulation can be relieved to a great extent.

Owner:徐州中伦光伏材料有限公司

Stainless steel slag drying and winnowing device and its drying and winnowing method

The invention relates to the technical field of steel slag processing in metallurgical industry, and discloses a stainless steel slag drying and air separation device and a drying and air separation method. The stainless steel slag drying and air separation device comprises a hopper, a bar screen, a bucket elevator, a drying kiln, a cyclone dust collector and a bag dust collector, the drying kiln is internally provided with a lifting plate, a combustion fan and an air blower, the bottom end of the drying kiln is provided with an aggregate outlet, and the upper part of a material outlet of the drying kiln is provided with a powder outlet. The stainless steel slag drying and air separation device integrates drying and air separation in a whole, after preliminary screening of a stainless steel slag raw material, the stainless steel slag is dried and by the drying kiln, meanwhile the air separation is performed, metal-containing material enrichment is facilitated, powder with smaller particle size is collected by the cyclone dust collector, and the bag dust collector can prevent the dust from discharging into the atmosphere; the device wear caused by the stainless steel slag can be reduced, the device service life can be prolonged, production cost can be reduced, wet processing water consumption and water treatment cost can be reduced, and energy saving and emission reduction can be achieved.

Owner:甘肃润源环境资源科技有限公司

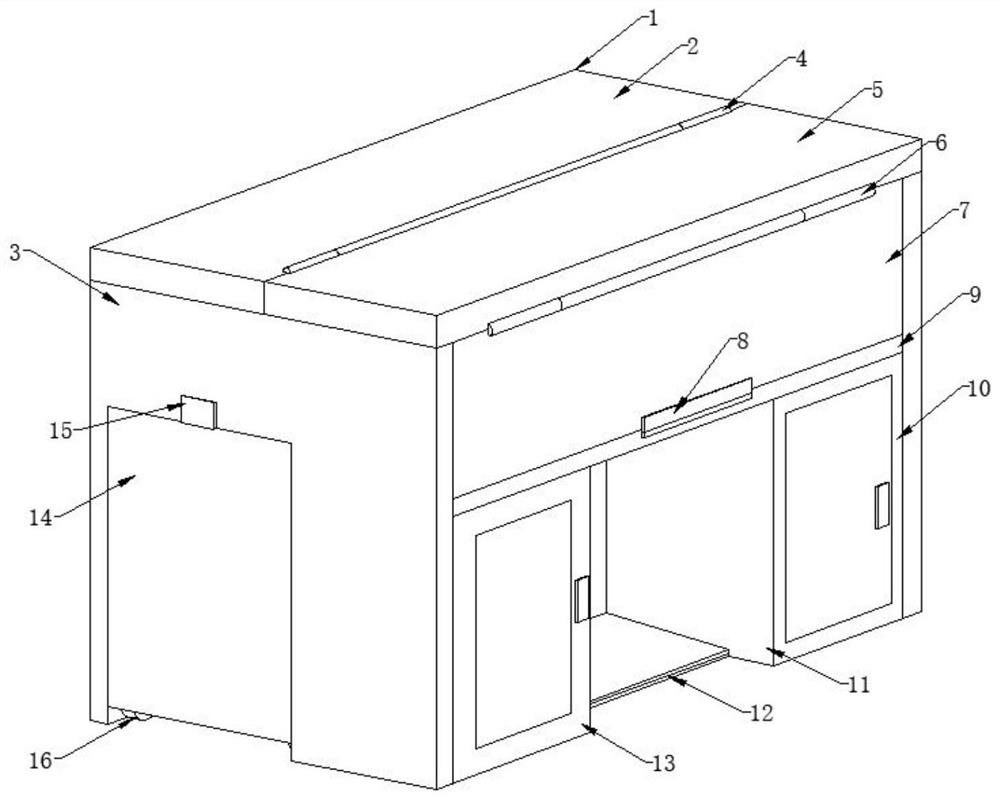

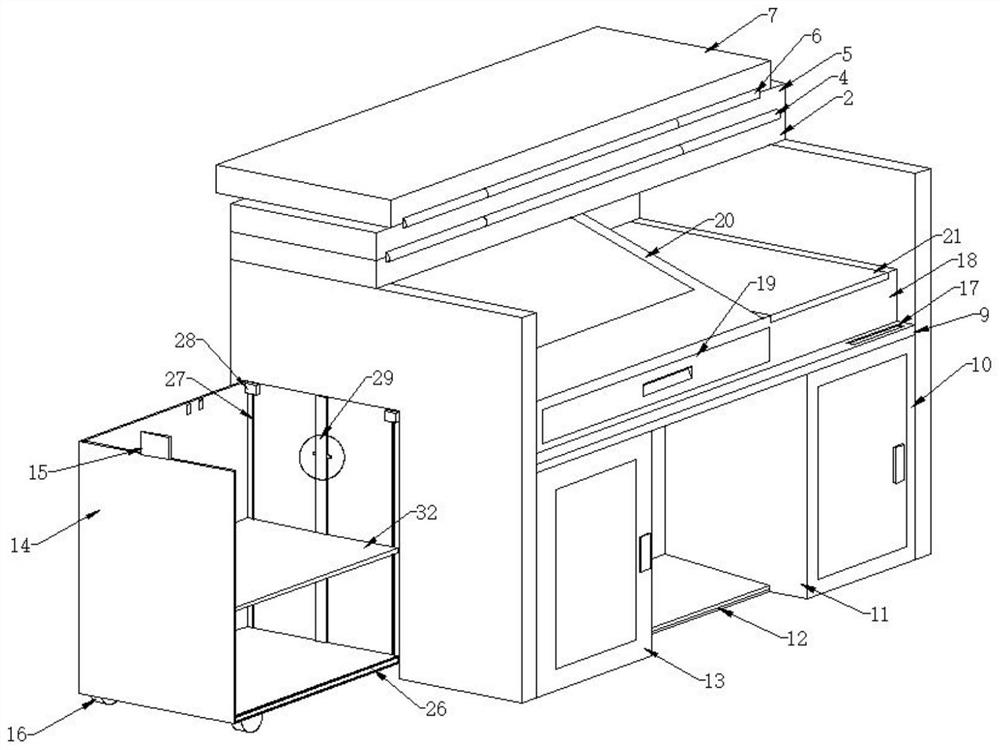

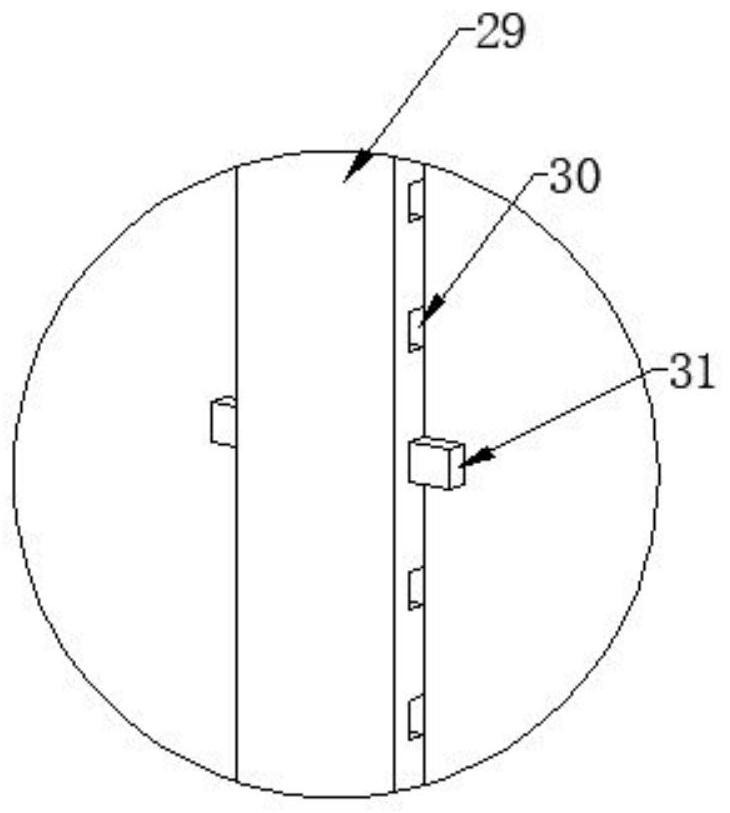

Multimedia platform for higher vocational Chinese teaching

PendingCN112869354AReduce oxidationReduce dust collectionPulpitsLecternsInterior spaceElectrical and Electronics engineering

The invention discloses a multimedia platform for higher vocational Chinese teaching. The multimedia platform comprises a platform body, a fixing plate is installed at the top end of the platform body, a main machine cabinet is installed on one side of the bottom end of a partition plate, a pit is formed in one end of the main machine cabinet, a pedal is installed at the bottom end of the inner side of the pit, a containing cabinet is installed at one end of the pit, and a side cabinet is installed on the surface of a side plate on one side; self-locking buckles are installed at the top ends of the side cabinets, a containing table is arranged on the inner surface of the top end of the partition plate, a display platform is arranged on one side of the top end surface of the containing table, and a sliding plate is installed at one end of the display platform. According to the multimedia platform capable of conveniently sealing the external equipment, when the multimedia platform is not used, the most basic keyboard and mouse on the surface of the multimedia platform can be placed in the internal space, so that oxidation and dust collection in external air are reduced.

Owner:刘世团

A h-shaped heat exchange tube

ActiveCN105674784BReduce dust collectionAchieve synergyTubular elementsEngineeringMechanical engineering

The invention provides an H-shaped heat exchange pipe which comprises a base pipe and multiple sets of fins. The multiple sets of fins are arranged on the base pipe at intervals in the axis direction of the base pipe, and each set of fins is parallel to the cross section of the base pipe. Each set of fins includes two fins, wherein the two fins are symmetric about the face where the axis of the base pipe is located. The cross section of the base pipe is rectangular. The fins are rectangular. A first opening and a second opening are formed between every two fins, wherein the first opening and the second opening are symmetric about the face where the axis of the base pipe is located. A finned pipe is provided so that the function of heat transfer strengthening can be met, and meanwhile dust accumulation can be relieved to a great extent.

Owner:徐州中伦光伏材料有限公司

Cyclone separating device

ActiveCN101301640BCompact structureSave installation spaceReversed direction vortexCycloneAir volume

The invention discloses a cyclone separator used for gas-solid or liquid-solid separation, comprising a gas riser, an air outlet, an air inlet, a straight cylinder section, a separation deposition cone section, a dust outlet, and a wearable layer. The cyclone separator is characterized in that the separation deposition cone section adopts a bent cone structure; the axis line track of the bent conestructure is an arc or an ellipse or other smooth transition curved lines. The cyclone separator is mainly used for the separation, recycling and exhaust of the wasted catalyst fine powders in the fourth-class cyclone separation system of a petroleum chemical fluid catalytic cracking device. The cyclone separator with the bent cone structure has installation height which is only one third of theinstallation height of a vertical cyclone separator, and is applicable to the design and reconstruction of devices with equipment installation space to be restricted; meanwhile, the bent-cone typed cyclone separator has simple structure, large wind disposal quantity and high efficiency; furthermore, as the liner material with high wearability is adopted, the cyclone separator of the invention canbe used under high temperature for a long time.

Owner:SINOPEC ENG +1

Military transport platform cleaning compound and cleaning method thereof

InactiveCN108485835ASave waterEliminate static electricityInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsSodium bicarbonateBetaine

The invention belongs to the technical field of a cleaning compound, and more specifically relates to a cleaning compound used for a military transport platform and a preparation method thereof, and acleaning method thereof. The cleaning compound comprises the following raw materials in parts by weight: A comprising 5 parts of diatomite, 4 parts of silicone oil, 2 parts of a nonionic surfactant,6 parts of Brazilian palm wax, 20 parts of polyacrylamide, 10 parts of sodium lauryl sulfate, 5 parts of sodium monolaurate sulfate, and 4 parts of dodecyl dimethyl betaine; and B comprising 4 parts of sodium dodecyl benzene sulfonate, 4 parts of sodium bicarbonate, 3 parts of isopropanol, 2 parts of triethanolamine, 2 parts of sodium phosphate, and 4 parts of polyoxyethylene nonyl phenyl ether; and C comprising 4 parts of a saponin extract, 4 parts of an orange extract, and 4 parts of turpentine.

Owner:JINAN JIAXING TECH

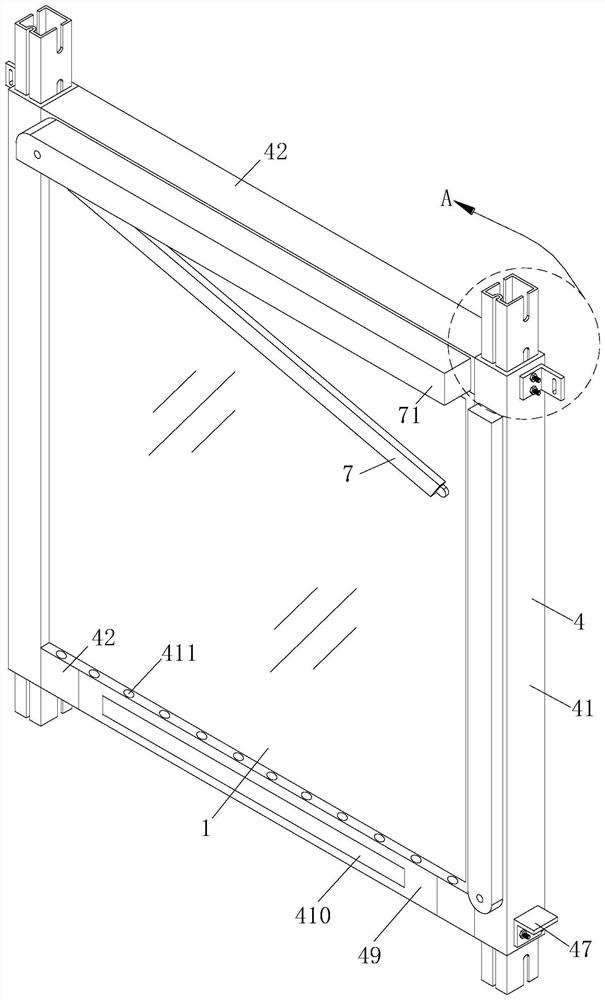

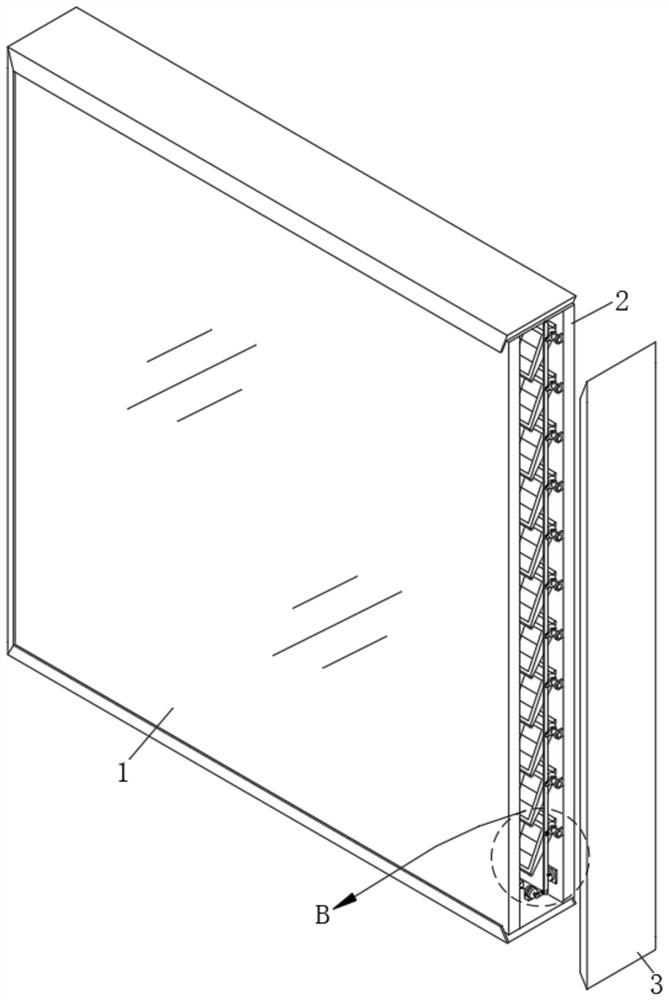

Component type heat preservation fireproof curtain wall structure and method thereof

PendingCN114439138AGood luminous fluxEasy to adjust the anglePhotovoltaic supportsSolar heating energyLight fluxCooling effect

The invention relates to the field of building curtain walls, in particular to a component type heat preservation fireproof curtain wall structure which comprises outer-layer glass, inner-layer glass is arranged on one side of the outer-layer glass, and a sealing piece is connected between the outer-layer glass and the inner-layer glass in a sealed mode. The angle of the photovoltaic mechanism is conveniently adjusted through the adjusting mechanism, so that the luminous flux of the curtain wall reaches the optimal state, and the comfort level of indoor personnel is improved; through the cleaning mechanism, the outer-layer glass easily contaminated with dirt can be conveniently cleaned, the permeability and attractiveness of the curtain wall are improved, and manual cleaning is avoided; the reciprocating mechanism facilitates repeated rubbing of the swinging cleaning component, so that the contact surface of the cleaning component and the glass is more uniform, less dust is collected, meanwhile, the noise is lower, and the cleaning effect of the curtain wall is better; through the cooperation of the water spraying mechanism and the cleaning mechanism, when a fire disaster occurs, only a thin plate arranged on the bottom beam needs to be crushed, water flows out of the bottom beam, and therefore the fire extinguishing and cooling effects are achieved.

Owner:张严

Dust removal system and dry sweeper with same

ActiveCN112012146BReduce dust collectionLong cleaning intervalsHuman health protectionUsing liquid separation agentWater vaporRoad sweeper

The invention discloses a dust removal system and a dry road sweeper with the same. It sets a deflector at the air inlet to direct the airflow and garbage into the trash can. Most of the garbage settles at the bottom of the trash can under the action of gravity, and some light garbage, water vapor, and dust will flow out of the trash under the action of airflow. The bucket rises up, and the light garbage is blocked by the filter screen, and only the airflow mixed with water vapor and dust is allowed to enter the dust removal box. After the airflow mixed with water vapor and dust enters the dust removal box, the inertial water removal device captures the water vapor and most of the dust, and the second dust removal device only needs to remove a small part of dust mixed in the airflow, thus greatly reducing the second The dust removal capacity of the dust removal device and the dust removal interval of the second dust removal device are longer, which prolongs the effective working time and improves the cleaning efficiency. The dust removal operation is carried out through the cooperation of the inertial water removal device and the second dust removal device, and the overall dust removal effect is better. .

Owner:ZOOMLION ENVIRONMENTAL IND CO LTD

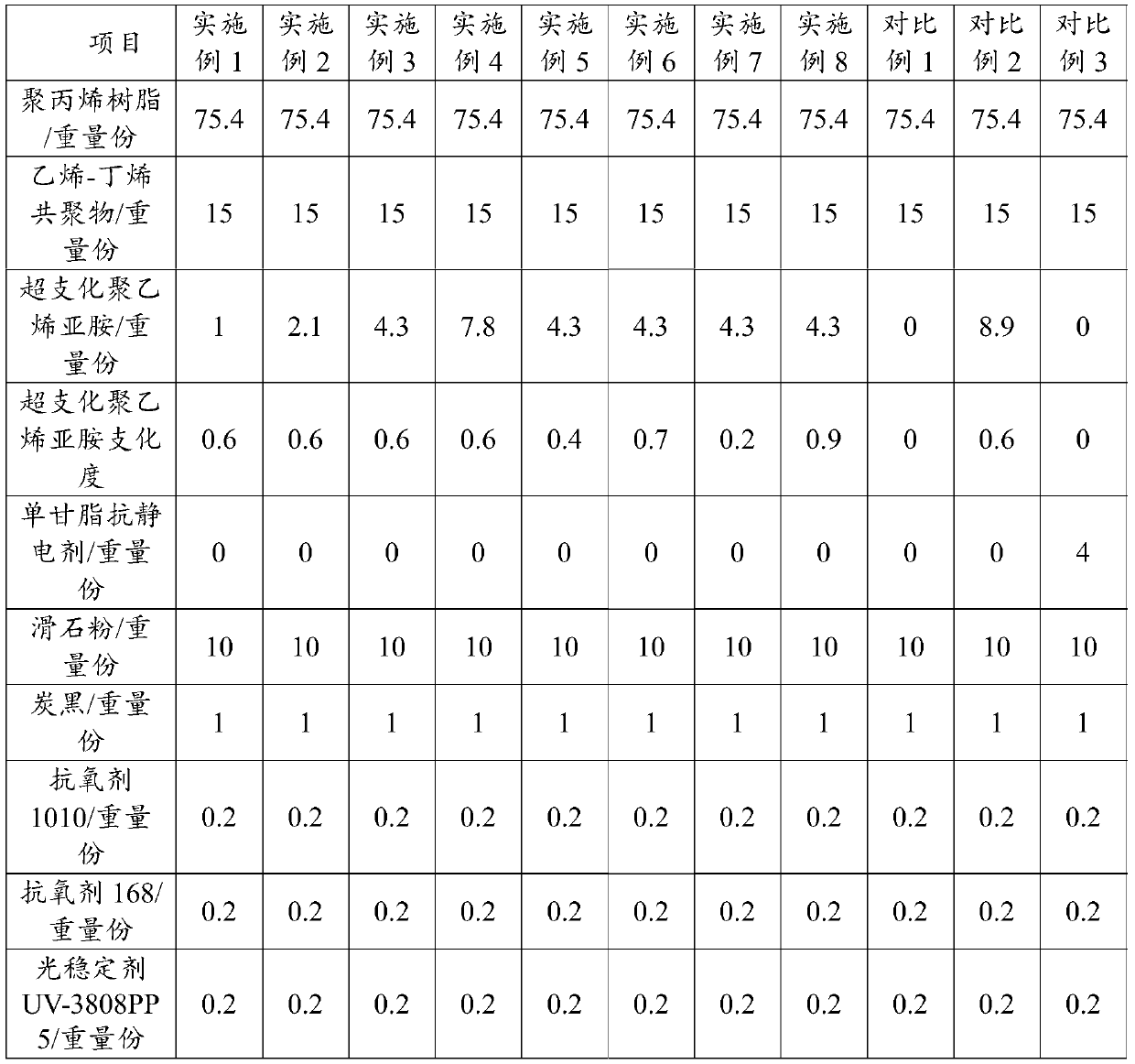

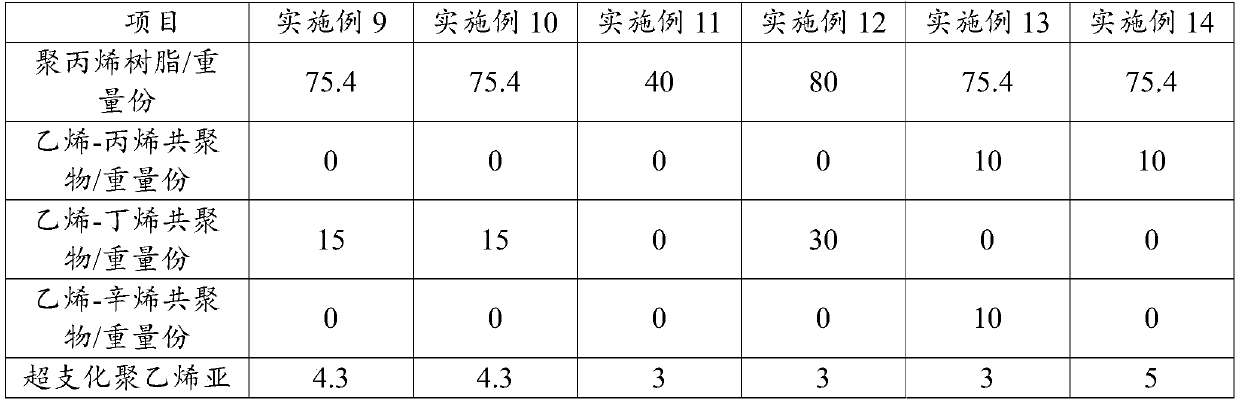

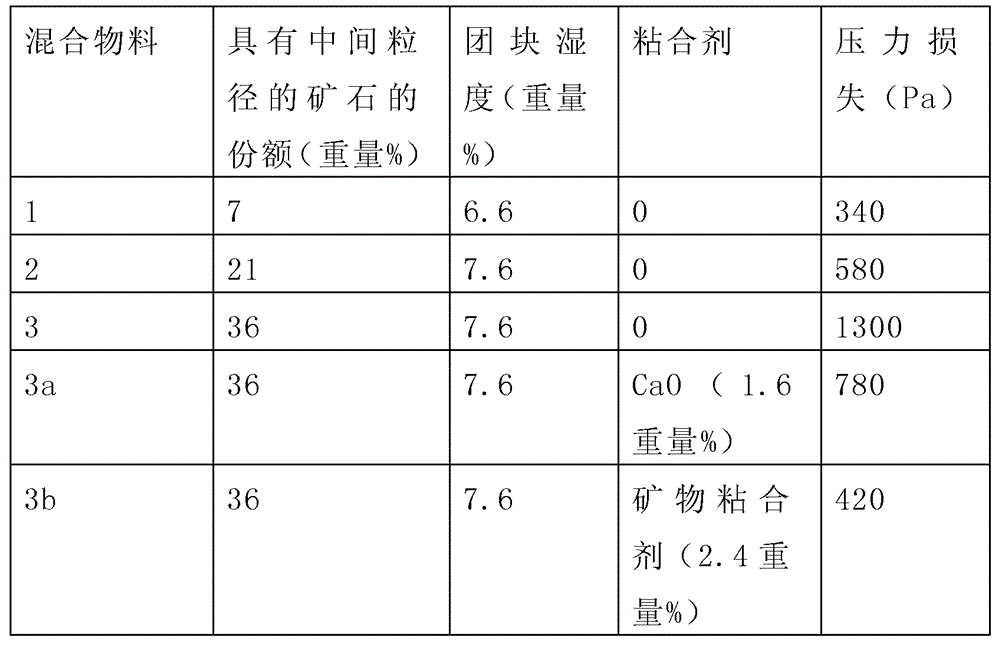

A kind of antistatic polypropylene composition

The invention discloses an antistatic polypropylene composition. The antistatic polypropylene composition is prepared from the following components in parts by weight: 40 to 80 parts of polypropyleneresin and 1 to 8 parts of antistatic agent, wherein the antistatic agent is hyperbranched polyethylenimine. According to the antistatic polypropylene composition disclosed by the invention, the hyperbranched polyethylenimine is added and is used as the antistatic agent; the tail end of the hyperbranched polyethylenimine contains a lot of amino groups; the amino groups absorb water in the air to become conductive, so that the surface resistivity is reduced, static electricity is eliminated and the composition has the antistatic effect; the antistatic polypropylene composition disclosed by the invention has excellent long-period antistatic property and mechanical property; the antistatic polypropylene composition can be used for preparing inner and outer ornaments of automobiles, improving the antistatic property, reducing the dust collection degree and keeping parts clean and beautiful.

Owner:KINGFA SCI & TECH CO LTD +1

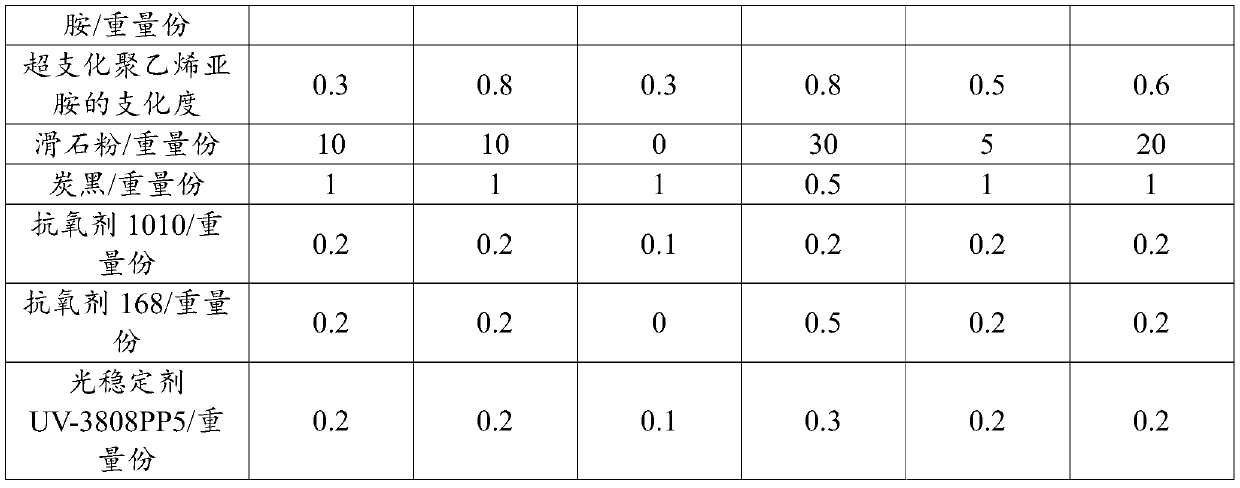

Process for the preparation of agglomerates for blast furnace feed from fine metal oxide-containing materials

ActiveCN102459658BImprove adhesionGood gas permeabilityBlast furnace detailsMaceralMaterials science

The invention relates to a method for the preparation of agglomerates for use as a blast furnace charge by making a fine material containing metals and / or metal oxides, a mineral binder with mineral raw materials and lime-like materials, and If necessary, the usual additives are mixed into agglomerates and the agglomerates are solidified into agglomerates, wherein a raw material is used as mineral raw material which has a silicon oxide fraction of at least 40% by weight and at least 20% by weight of particle sizes smaller than A fraction of ultrafine particles of 4 μm, and a fraction of particles with a particle size of less than 1 μm of 10% by weight. The invention also relates to a blast furnace charge, which can be prepared by the method according to the invention, and to a premix for preparing the blast furnace charge.

Owner:PHEINKALK GMBH

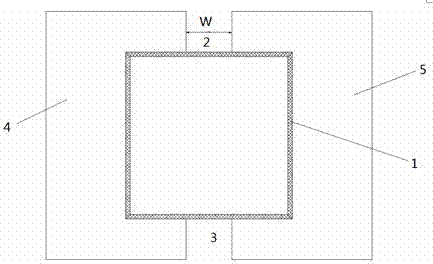

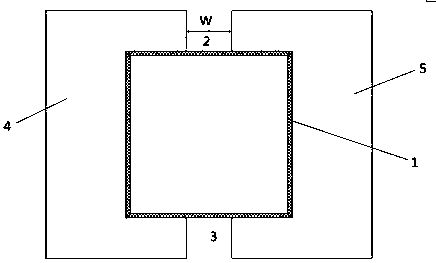

An anti-corrosion finned tube

ActiveCN105737662BReduce corrosionReduce dust collectionHeat exhanger finsAnti-corrosive paintsEngineering

The invention provides a finned tube. The finned tube comprises a base tube and transverse fins arranged on the base tube, wherein the base tube and the fins are coated with anticorrosive layers. According to the finned tube, by arranging the anticorrosive layers, the finned tube can be prevented from being corroded in the heat exchange process, and the heat exchange effect can be further improved.

Owner:TAICANG CENTURY PORT GARMENT CO LTD

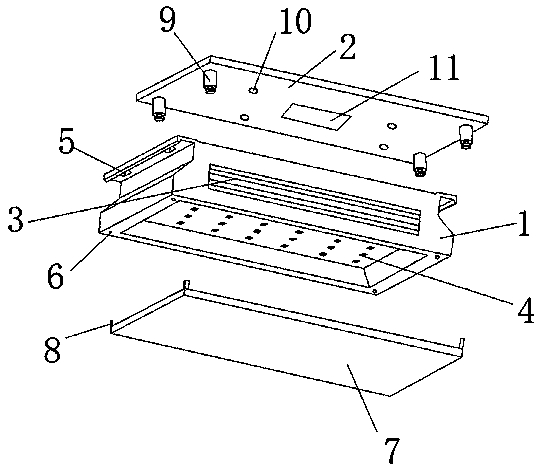

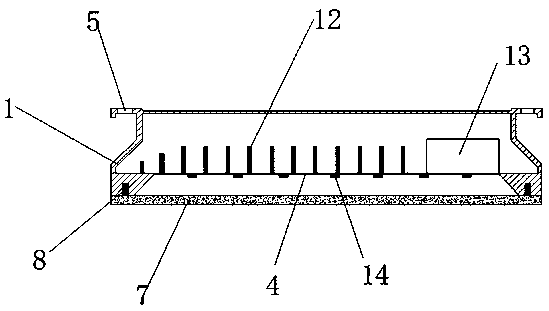

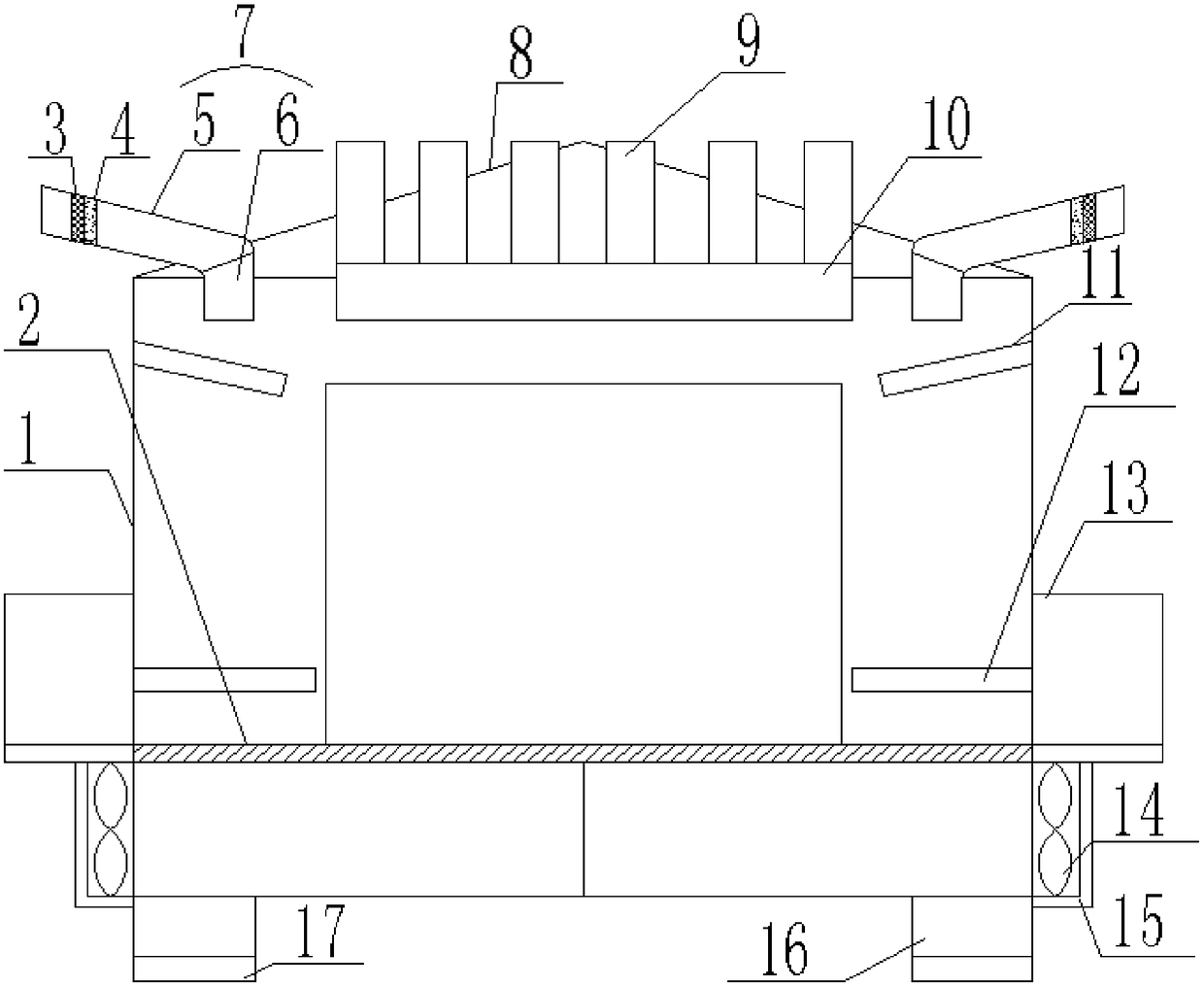

Efficient heat dissipation type LED lamp convenient to install

InactiveCN110822335AAvoid damageAvoid the risk of damaging electrical components inside the luminaireLighting heating/cooling arrangementsLight fasteningsEngineeringLED lamp

The invention discloses an efficient heat dissipation type LED lamp convenient to install. The efficient heat dissipation type LED lamp comprises a lamp body; the two sides of the lamp body are provided with heat dissipation air openings; a PCB is arranged inside the lamp body; LED lamp beadsarearranged on the lower surface of the PCB; heat dissipation finsarearranged at the upper end of the PCB;a driver is arranged at one sides of the heat dissipation fins; grooves are arranged at the four corners of the lower end of the lamp body; a lamp cover is arranged below the lamp body; convex edges are arranged at four corners of the upper end of the lamp cover; mounting sliding ports are arranged at four corners of the upper end of the lamp body; a mounting disk is arranged above the lamp body;mounting screw holes are arranged in the surface of the mounting disk; a connecting line penetrating hole is arranged between the mounting screw holes; and inlaid convex columns are arranged around the surface of the mounting disk. The efficient heat dissipation type LED lamp convenient to install provided by the invention has simpler structure, faster heat dissipation, light distribution in all directions and uniform light projection, has the characteristics of being high in light efficiency and high in service life, and is wide in application range and convenient to popularize and use.

Owner:曾宋华

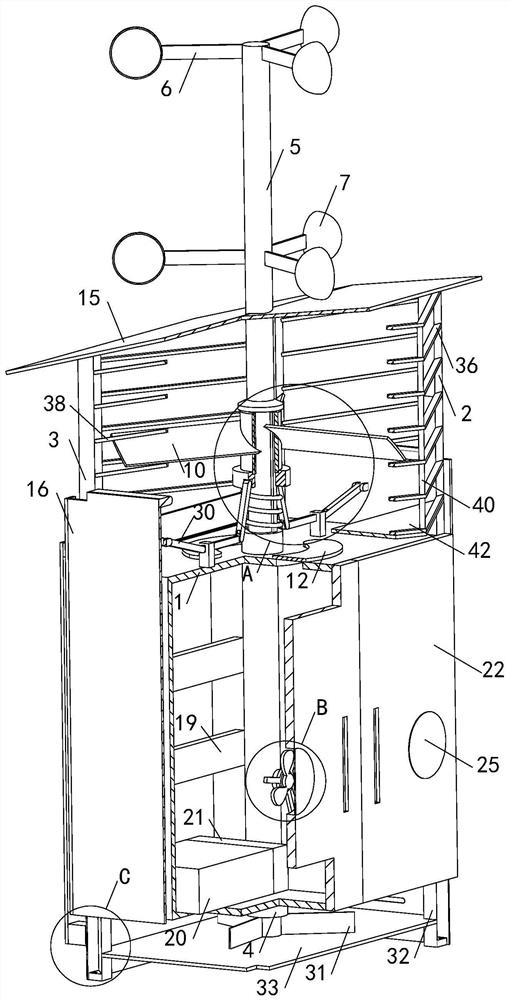

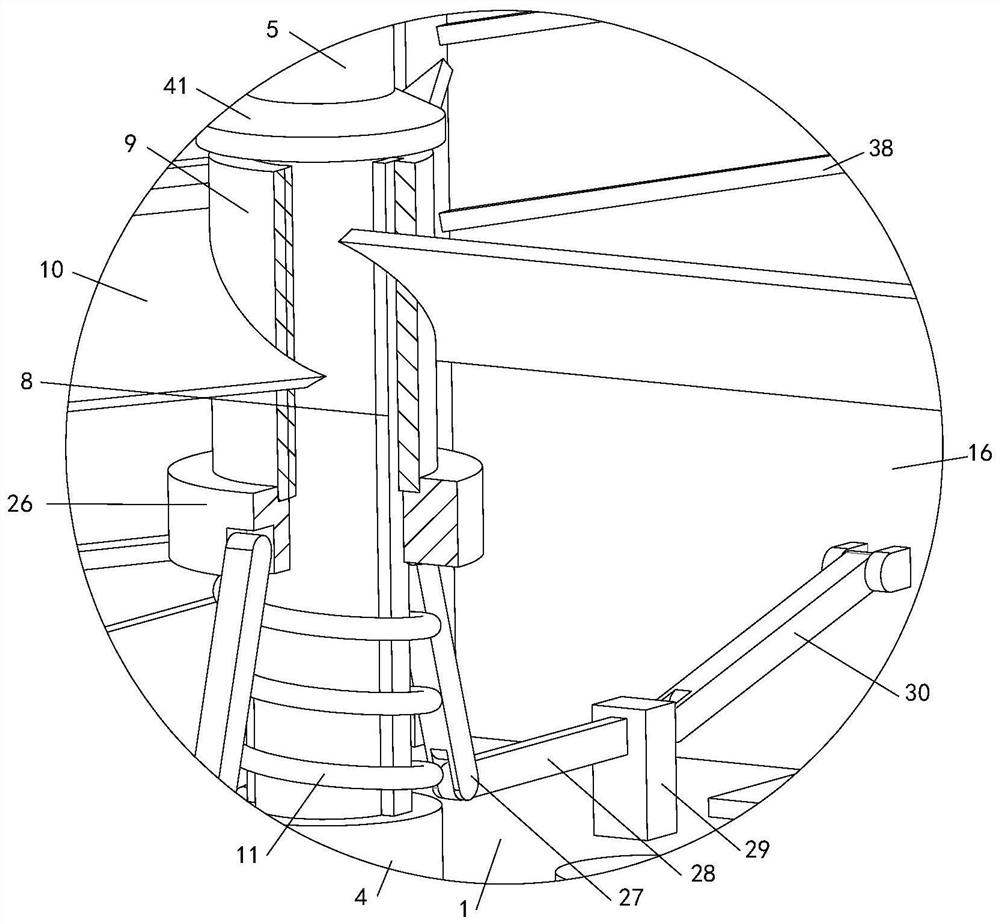

Energy-saving heat dissipation type high-voltage cabinet

ActiveCN112490911AIncrease the installation areaEasy to drivePV power plantsSubstation/switching arrangement cooling/ventilationThrust bearingEngineering

The invention relates to the technical field of high-voltage cabinets, in particular to an energy-saving heat dissipation type high-voltage cabinet which comprises a cabinet body, two long supportingcolumns and two short supporting columns, the two long supporting columns and the two short supporting columns are connected with the cabinet body, the cabinet body is connected with a vertical shaftthrough two thrust bearings, and the vertical shaft is connected with a plurality of driving sleeves and a plurality of driving strips. The vertical shaft is connected with a plurality of fan blades through an installation ring, the installation ring is connected with a traction mechanism, a tension spring is connected between the traction mechanism and the thrust bearing, close to the upper side,of the two thrust bearings, the cabinet body is provided with an annular filtering dustproof plate and a back plate, and the two long supporting columns and the two short supporting columns are connected with inclined frames. The long supporting column and the short supporting column are connected with a fan-shaped support through a wing support, the wing support is connected with a traction mechanism, solar cell panels are installed on the back plate, the inclined frames, the wing support and the fan-shaped support, a storage battery and a generator are installed in the cabinet body, and thecabinet body is connected with two installation door mechanisms. Energy is saved, use is clean, heat dissipation is stable, and the practicability is high.

Owner:孔祥富

Energy-saving server heat radiation device

InactiveCN108268107AImprove cooling effectPrevent outflowDigital data processing detailsEnergy efficient computingTemperature controlEngineering

The invention discloses an energy-saving server heat radiation device, which belongs to the technical field of a computer server and is used for solving the problems of high cost and energy source waste of the existing server heat radiation device. The energy-saving server heat radiation device comprises a box body, a first heat radiation assembly, a second heat radiation assembly and a temperature control assembly, wherein the first heat radiation assembly comprises a ventilation pipe and an exhaust fan; the ventilation pipe comprises a first ventilation pipe and a second ventilation pipe; aflow guide plate is arranged under the second ventilation pipe and is arranged on the side wall of the box body in an inclined way; the exhaust fan is arranged at the bottom of the box body; the second heat radiation assembly comprises a heat radiation device and a heat conduction sheet; the heat radiation device is arranged on the top wall of the box body; the heat conduction sheet is arranged onthe heat radiation device; a support frame used for putting the server is arranged inside the box body; the temperature control assembly comprises a temperature detector and a control switch; the temperature detector is arranged inside the box body; the control switch is arranged on the side wall of the box body and is respectively and electrically connected with the temperature detector and theexhaust fan.

Owner:河南趣读信息科技有限公司

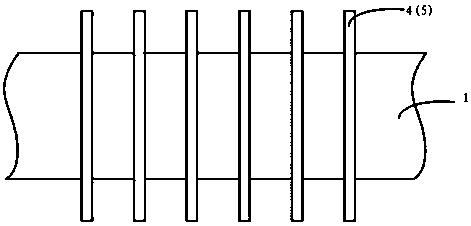

Finned tube with variable axial spacing of fins

ActiveCN105651097AMaximum absorptionImprove heat transfer performanceTubular elementsEngineeringThermodynamics

Owner:DAYE QIFENG POWER REFRIGERATION EQUIP CO LTD

Stainless steel slag drying and air separation device and drying and air separation method

The invention relates to the technical field of steel slag processing in metallurgical industry, and discloses a stainless steel slag drying and air separation device and a drying and air separation method. The stainless steel slag drying and air separation device comprises a hopper, a bar screen, a bucket elevator, a drying kiln, a cyclone dust collector and a bag dust collector, the drying kiln is internally provided with a lifting plate, a combustion fan and an air blower, the bottom end of the drying kiln is provided with an aggregate outlet, and the upper part of a material outlet of the drying kiln is provided with a powder outlet. The stainless steel slag drying and air separation device integrates drying and air separation in a whole, after preliminary screening of a stainless steel slag raw material, the stainless steel slag is dried and by the drying kiln, meanwhile the air separation is performed, metal-containing material enrichment is facilitated, powder with smaller particle size is collected by the cyclone dust collector, and the bag dust collector can prevent the dust from discharging into the atmosphere; the device wear caused by the stainless steel slag can be reduced, the device service life can be prolonged, production cost can be reduced, wet processing water consumption and water treatment cost can be reduced, and energy saving and emission reduction can be achieved.

Owner:甘肃润源环境资源科技有限公司

A copper aluminum alloy finned tube

ActiveCN105758244BImprove heat resistanceImprove anti-corrosion abilityTubular elementsHeat resistanceAlloy

Owner:盐城市轩源加热设备科技有限公司

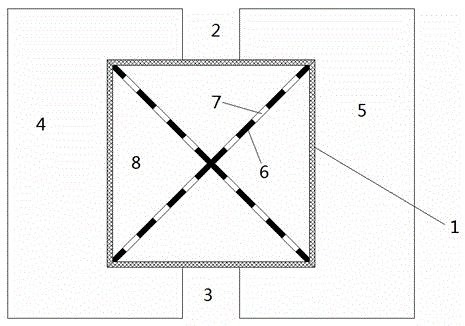

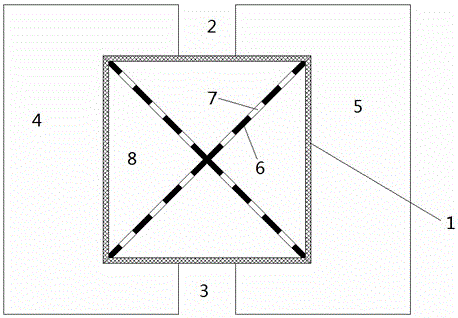

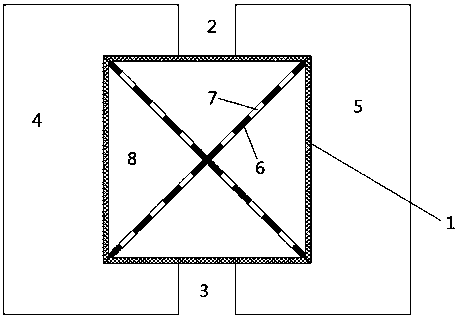

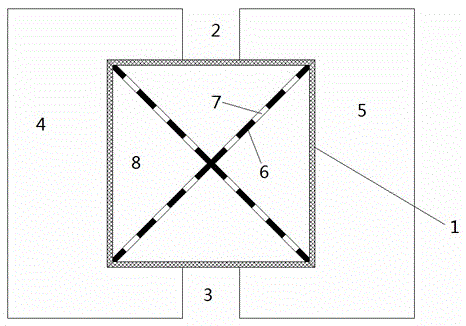

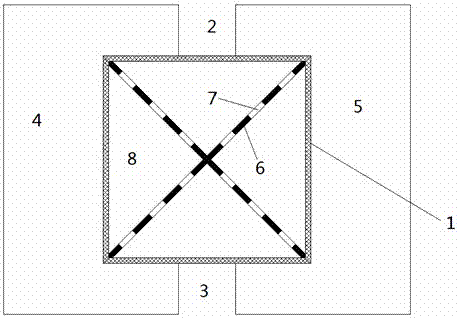

A rectangular cross-section finned tube

ActiveCN105737661BImprove heat transfer performanceReduce dust collectionTubular elementsEngineeringHeat distribution

The invention provides a rectangular transverse-section finned tube. The finned tube comprises a base tube and transverse fins arranged on the base tube, wherein the base tube and the transverse fins are rectangular. According to the finned tube, by arranging the rectangular fins and the rectangular base tube, the base tube and the fins have the same shape, the heat exchange field can be synergetic, the heat distribution direction and the transmission amount can be basically identical in the circumferential direction, and therefore heat transfer can be further improved.

Owner:扬州旻阳传热科技有限公司

Electrostatic precipitator, charge control program for electrostatic precipitator, and charge control method for electrostatic precipitator

ActiveUS10328437B2Excellent advantageous effects of suppressing occurrence of back coronaReduce dust collectionExternal electric electrostatic seperatorElectric supply techniquesPower flowCharge control

Owner:MITSUBISHI HITACHI POWER SYSTEMS ENVIRONMENTAL SOLUTIONS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com