Vertical winnowing pulverizer for zirconium fluidizing chlorination industry

A wind separation pulverizer, boiling chlorination technology, applied in the direction of grain processing, etc., can solve the problems of unscientific particle size control data, particle size mismatch, and reduced yield, so as to achieve long continuous production time and reduced slag discharge times , High yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

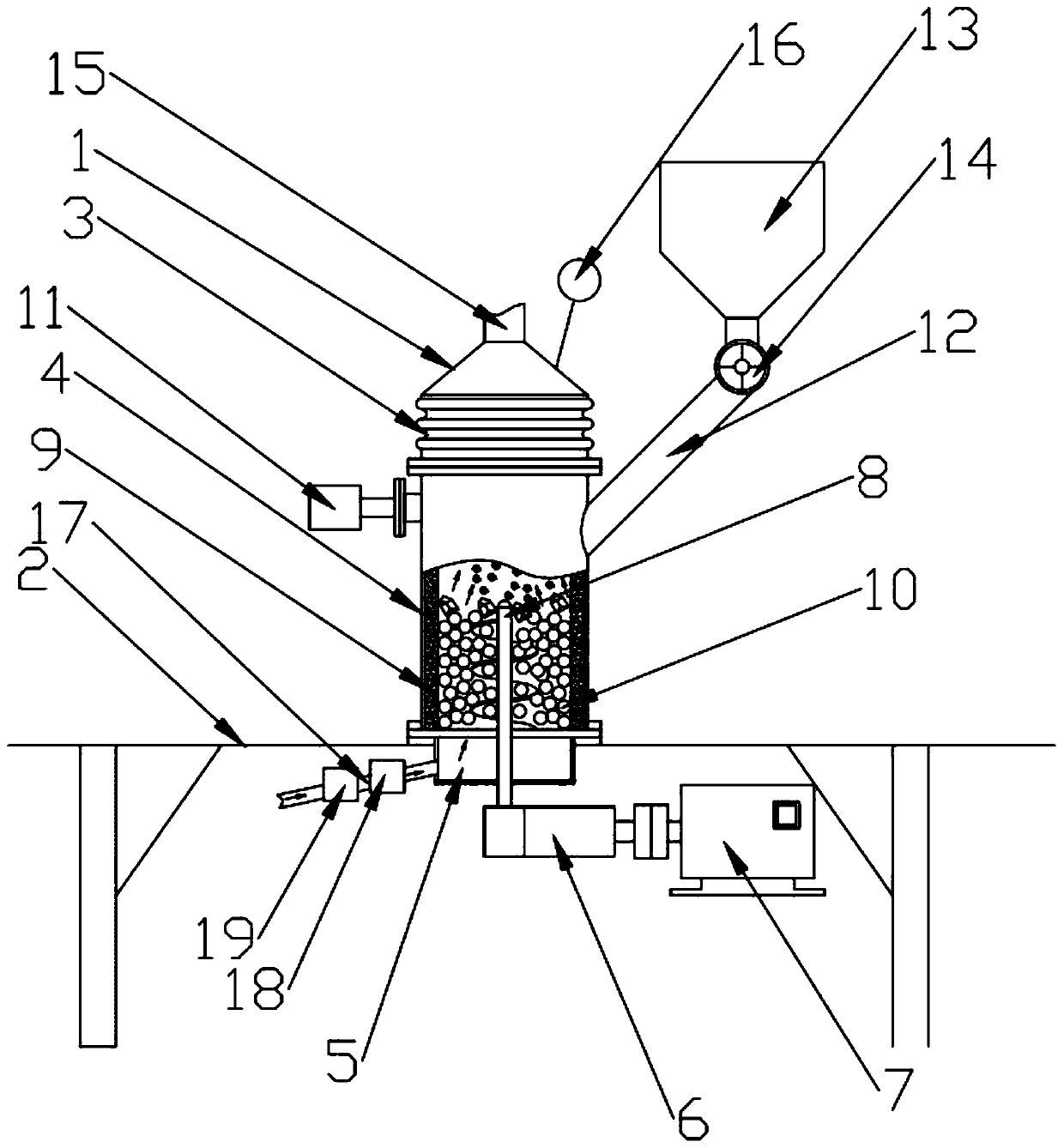

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0022] In conjunction with the accompanying drawings, a vertical winnowing pulverizer for zirconium boiling chlorination industry is characterized in that it includes a pulverizer main body 1, a frame 2 and a PLC, the pulverizer main body 1 is installed on the frame 2, The pulverizer main body 1 includes an adjustment section 3 at the top and a fixed section 4 at the bottom. An air distributor 5 is connected to the bottom of the fixed section 4. A reducer 6 is provided below the pulverizer main body 1. The reducer 6 is directly connected to the motor 7, the top of the reducer 6 is provided with an agitator 8 extending into the interior of the fixed section 4, the inner wall of the fixed section 4 is provided with a zirconium liner 9, and the interior of the fixed section 4 is provided with an oxidation Zirconium ball 10, a level gauge 11 is provided on one si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com