Automated container storage and delivery system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

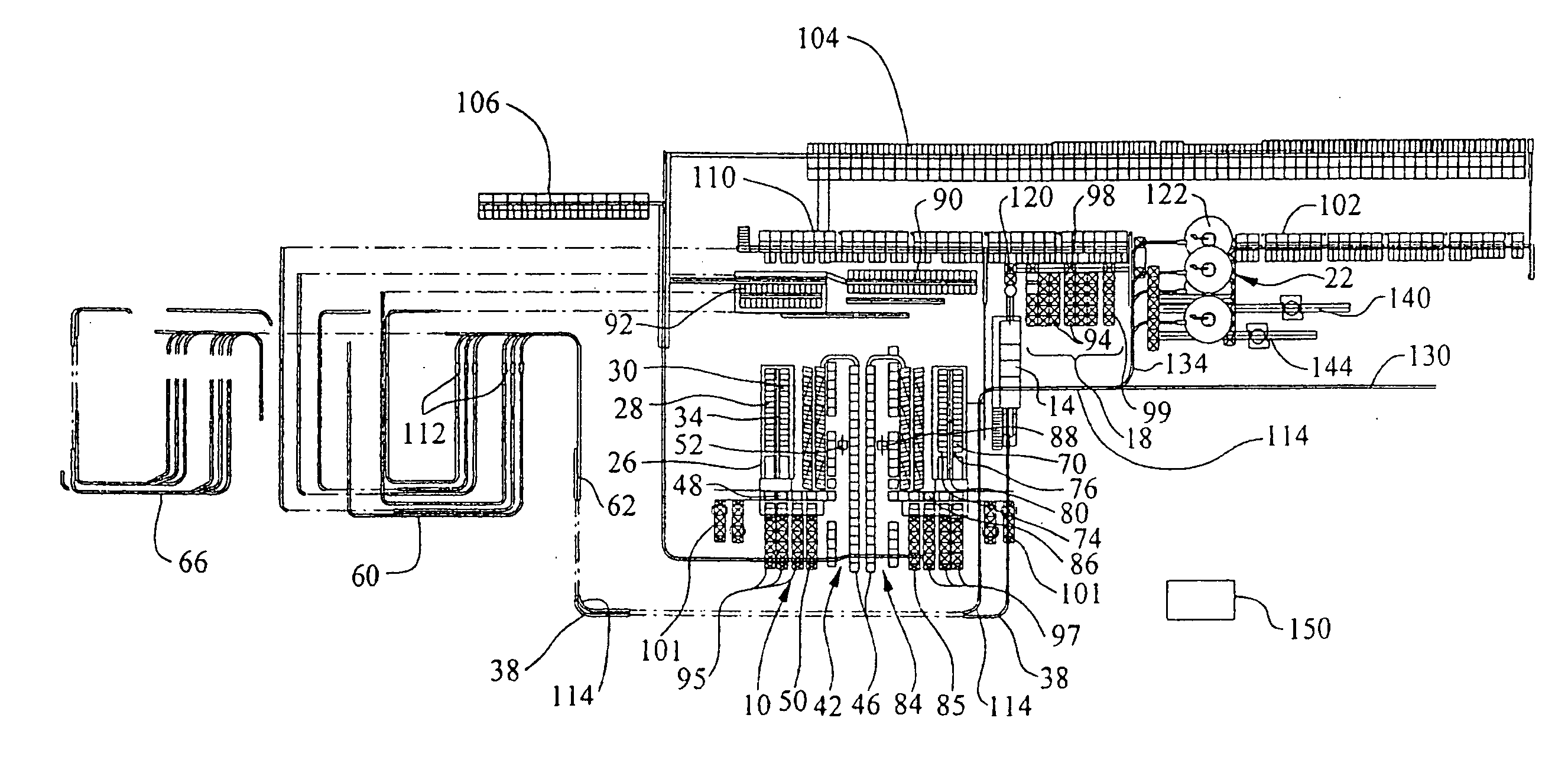

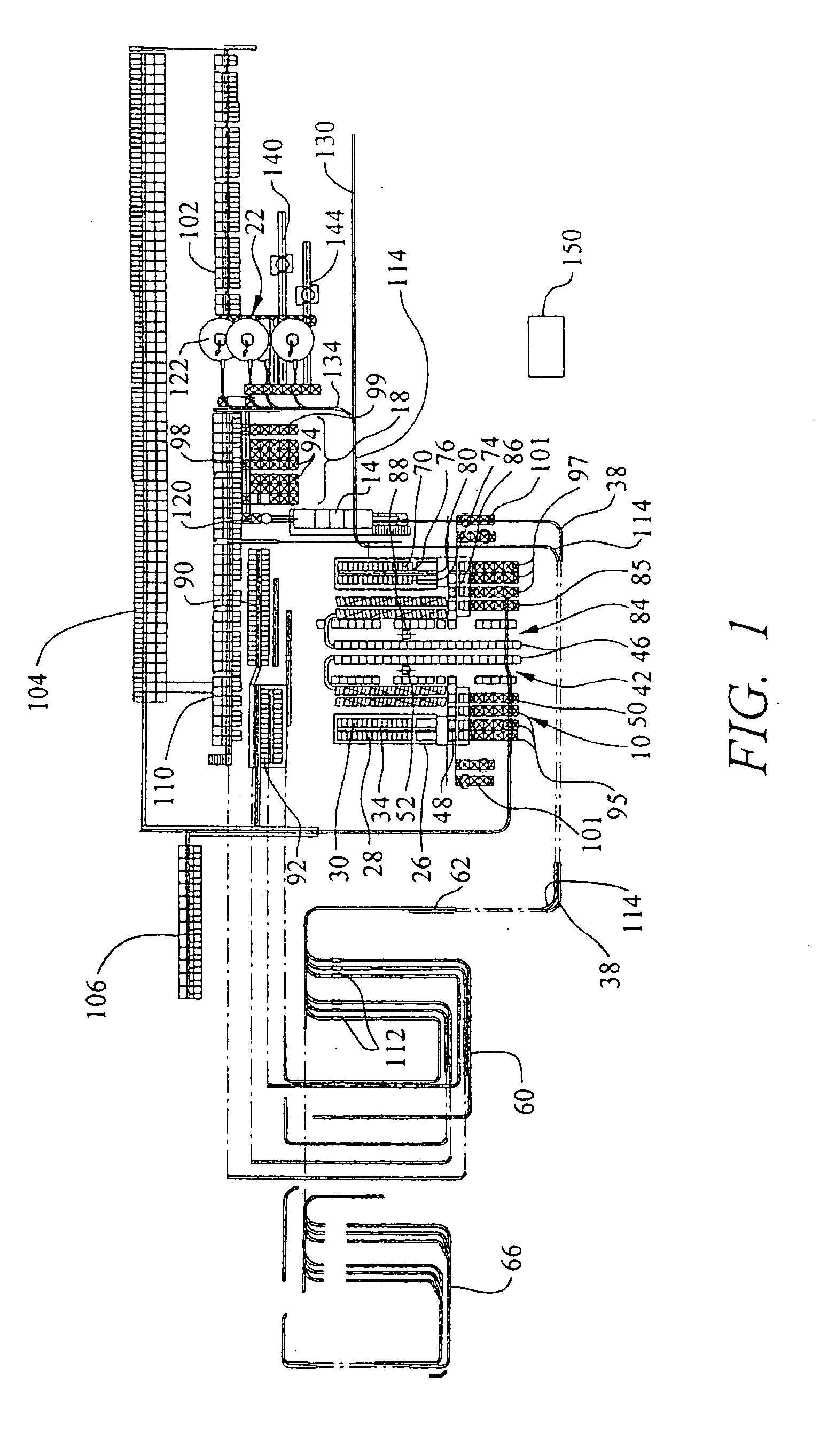

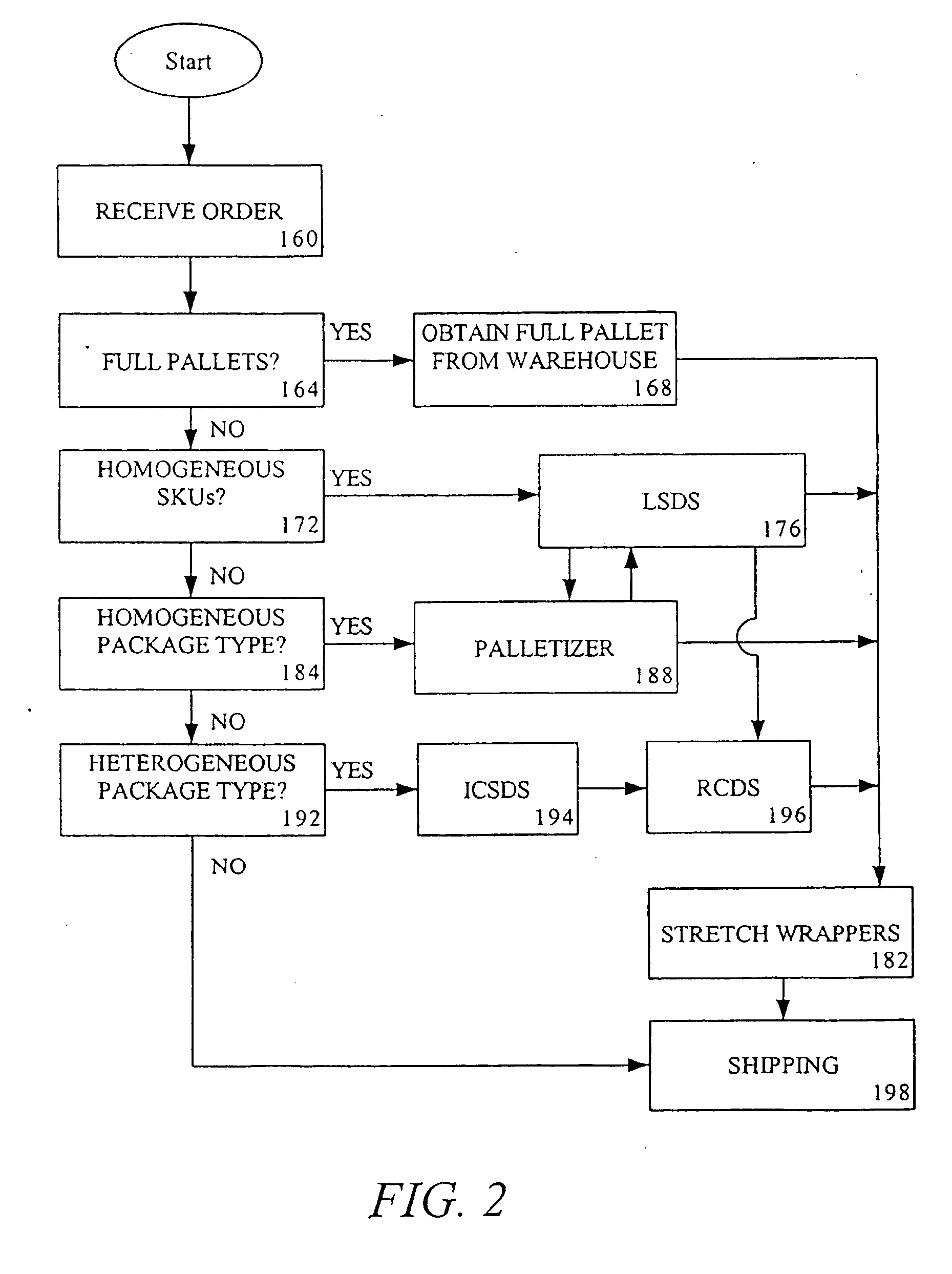

[0020] A top plan schematic of an automated storage and retrieval system according to the invention is shown in FIG. 1. The system comprises an individual container storage and delivery system (ICSDS) 10. A palletizer 14 receives containers from the ICSDS 10 and places them onto a pallet. A layer storage and delivery system (LSDS) 18 places full layers of containers on a pallet. A robotic container delivery system (RCDS) 22 places individual containers onto a pallet.

[0021] The term “container” is used herein generally, and can refer to almost any type of goods for which material handling is necessary. The invention is useful for beverage containers and product containers of many different sizes and shapes. The invention is also useful for the handling of containers within containers, as when cans of beverages are provided in packages, and such packages are in provided in cases. The invention can also be used to move goods themselves, where such goods may not be in a container as su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com