Suspension rotation type overhead stereoscopic warehouse system

A three-dimensional warehouse and rotary technology, which is applied in the field of warehouse goods management, can solve problems such as difficulty in meeting actual production needs, and achieve the effects of reducing working time, saving energy and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Example 1 Colored cotton spinning factory colored cotton raw material warehouse

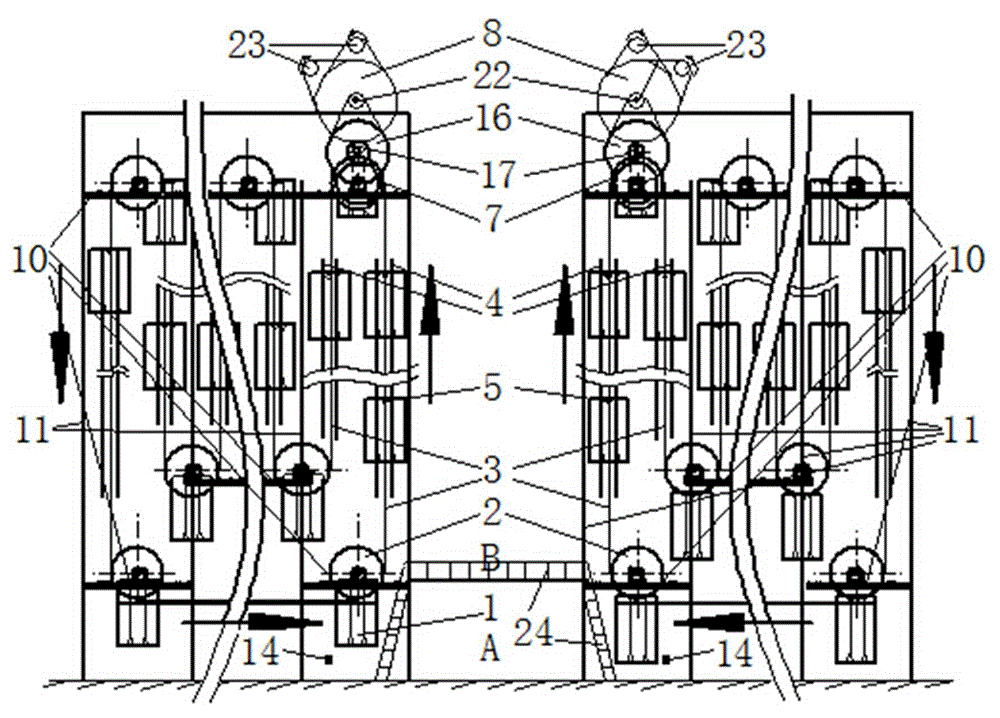

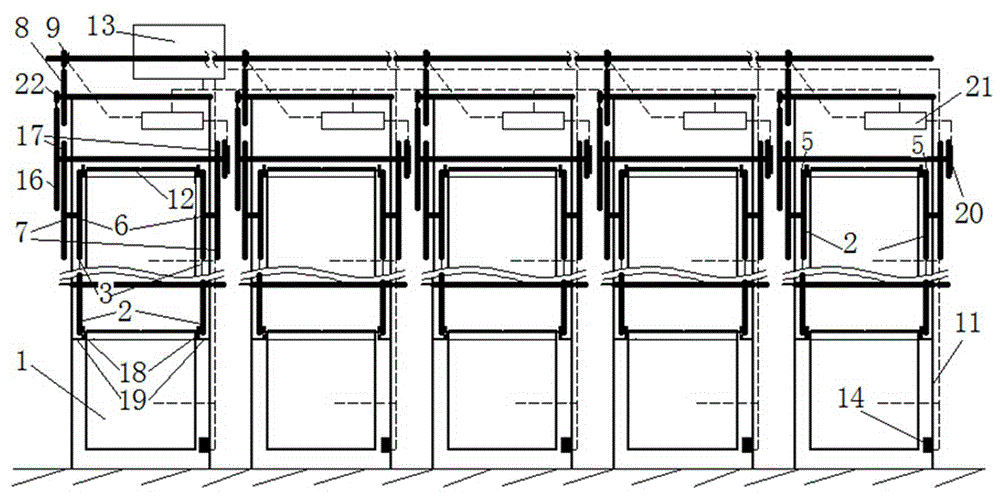

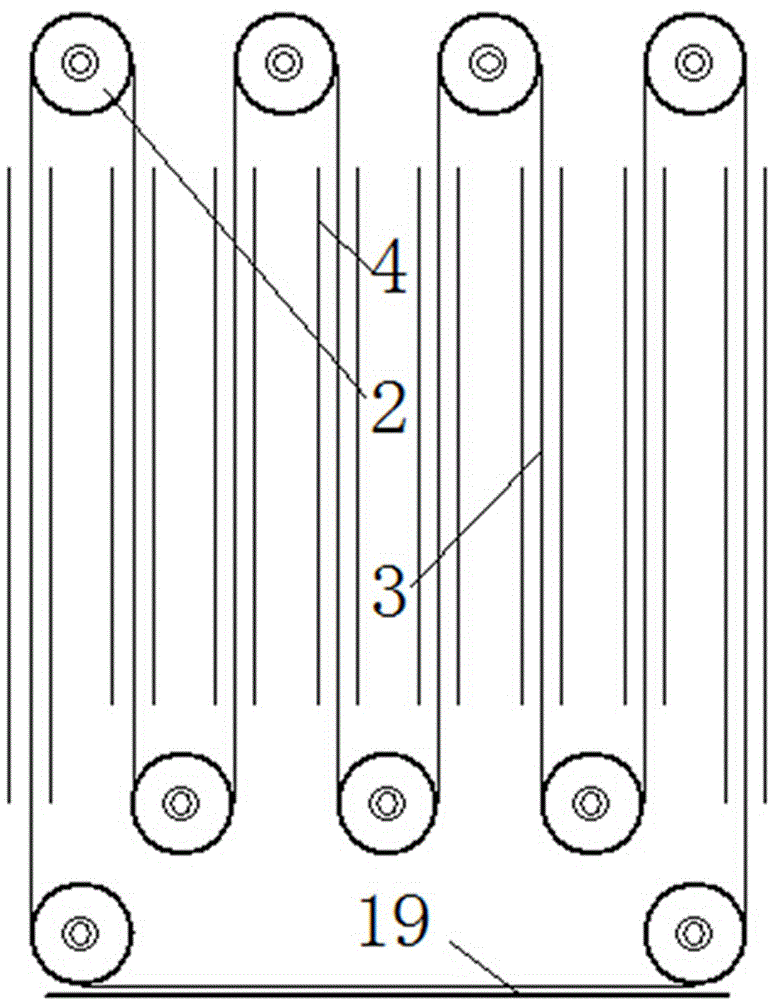

[0049] See Figure 1~Figure 9 .

[0050] figure 1 It is a side view of two power module storage units on the left and right, in which there are 2K vertical rows (K=1, 2, 3...n), multi-layer vertical, multi-arc and a horizontal multi-line closed-loop combined line on the left and right. There is a passage, and there are hanging rotary elevated three-dimensional warehouses on both sides of the passage, and become a large warehouse as a whole. The ground cargo access location A, and the cargo sampling location B (sampling platform) above the ground and the guardrail 24 are set near the passage.

[0051] The following uses the storage unit of the power module on the right for a specific description.

[0052] A plurality of hanging baskets 1 are equidistantly connected in series on closed-loop chains 3 with equal perimeters in the symmetrical planes on the left and right sides formed by up...

Embodiment 2

[0061] See Figure 10

[0062] The hanging goods can be large or small. The cars in modern cities use chain-suspended high-bay warehouses, which may be more convenient to access and have larger storage capacity. This is because the chain-suspended high-bay warehouse itself is a modular storage and retrieval of multiple powers. Determined by its own advantages, under the overall processing control of the computer, only the manipulator on the roadway floor is required to enter and exit the blue hanging frame, which is very simple, and the remaining tasks are carried out independently by each module without lifting and re-entry. It is exactly the same as that described in the manual, so it will be omitted here.

Embodiment 3

[0064] See Figure 11

[0065] The factory needs to be equipped with hardware warehouses for production, and the installation of production lines requires mechanical spare parts warehouses. They are very suitable for computerized automated management of automatic hanging goods blue hanging frame elevated warehouses, which can greatly improve management quality and efficiency. The specific process and The instructions are the same, because the hanging warehouse can stop at the multi-guided position for picking up goods according to the instructions of the computer, and people can carry out multi-layer division of labor (A, B, C, D) according to their needs, and the functionalization can pick up and ship goods nearby, which has obvious advantages.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com