Showcase assembly unit for showcase structure

a technology for assembly units and showcases, applied in the direction of chutes, dismountable cabinets, de-stacking articles, etc., can solve the problems of affecting the appearance of the showcase, causing jolting motion, and causing large nois

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

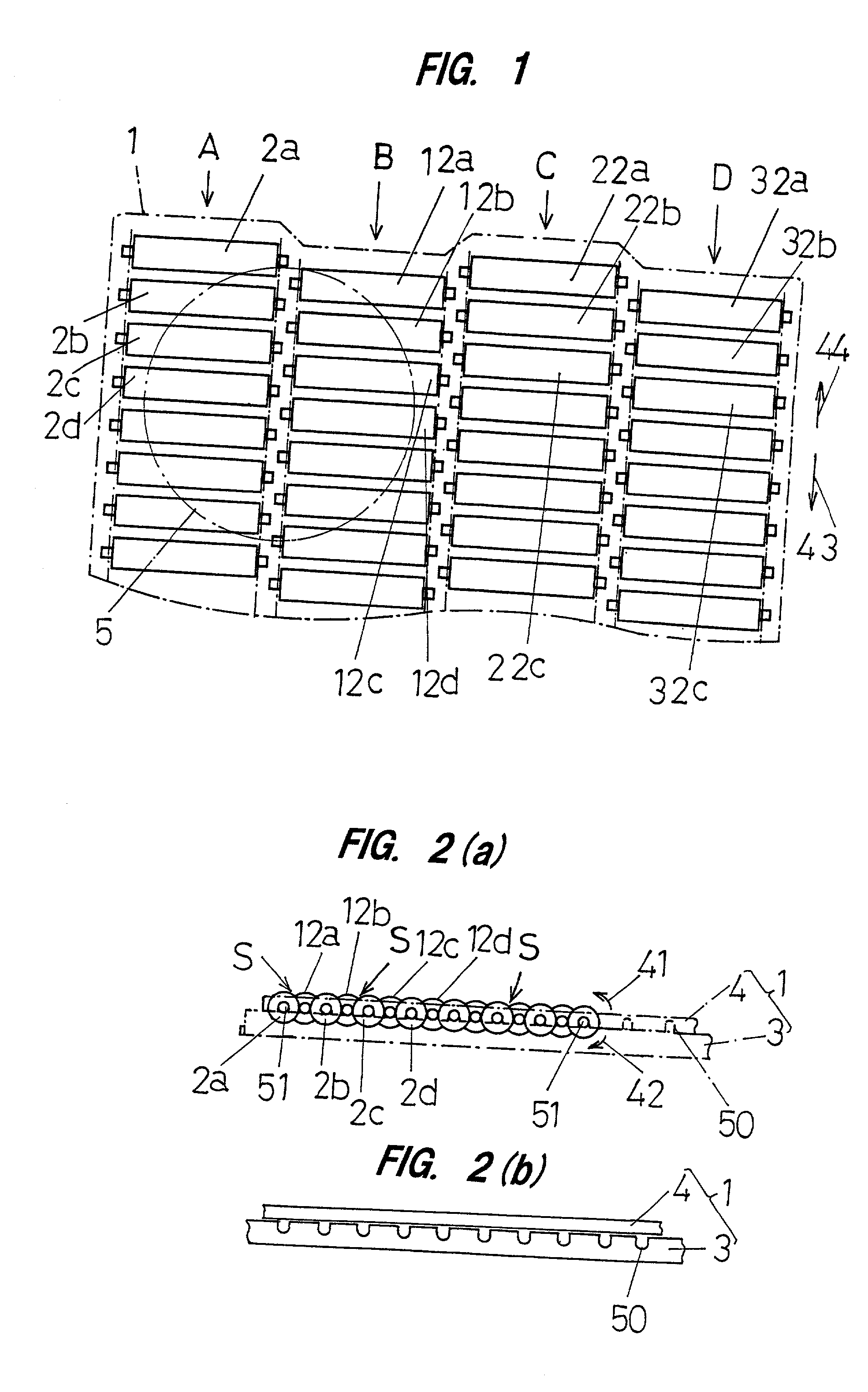

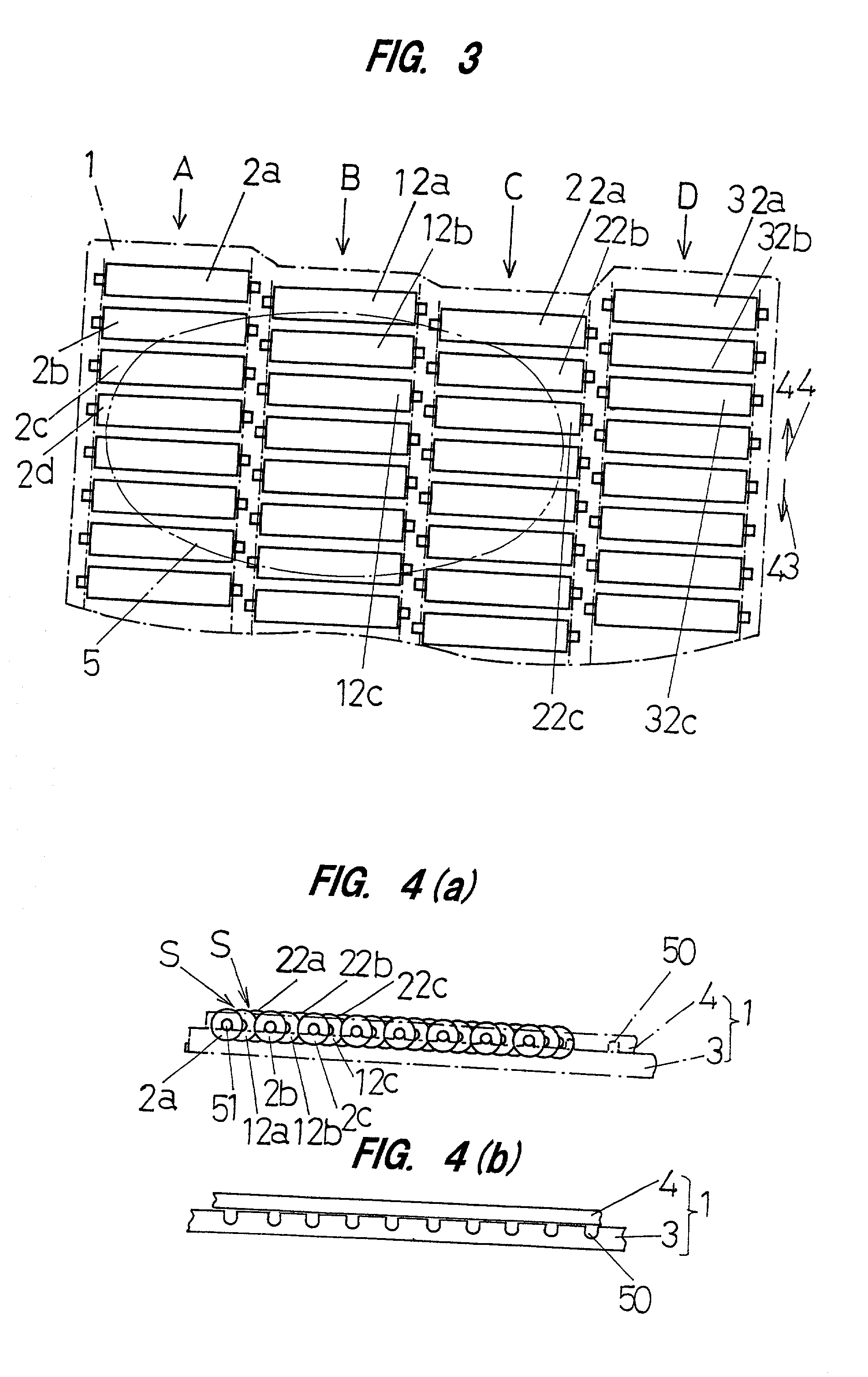

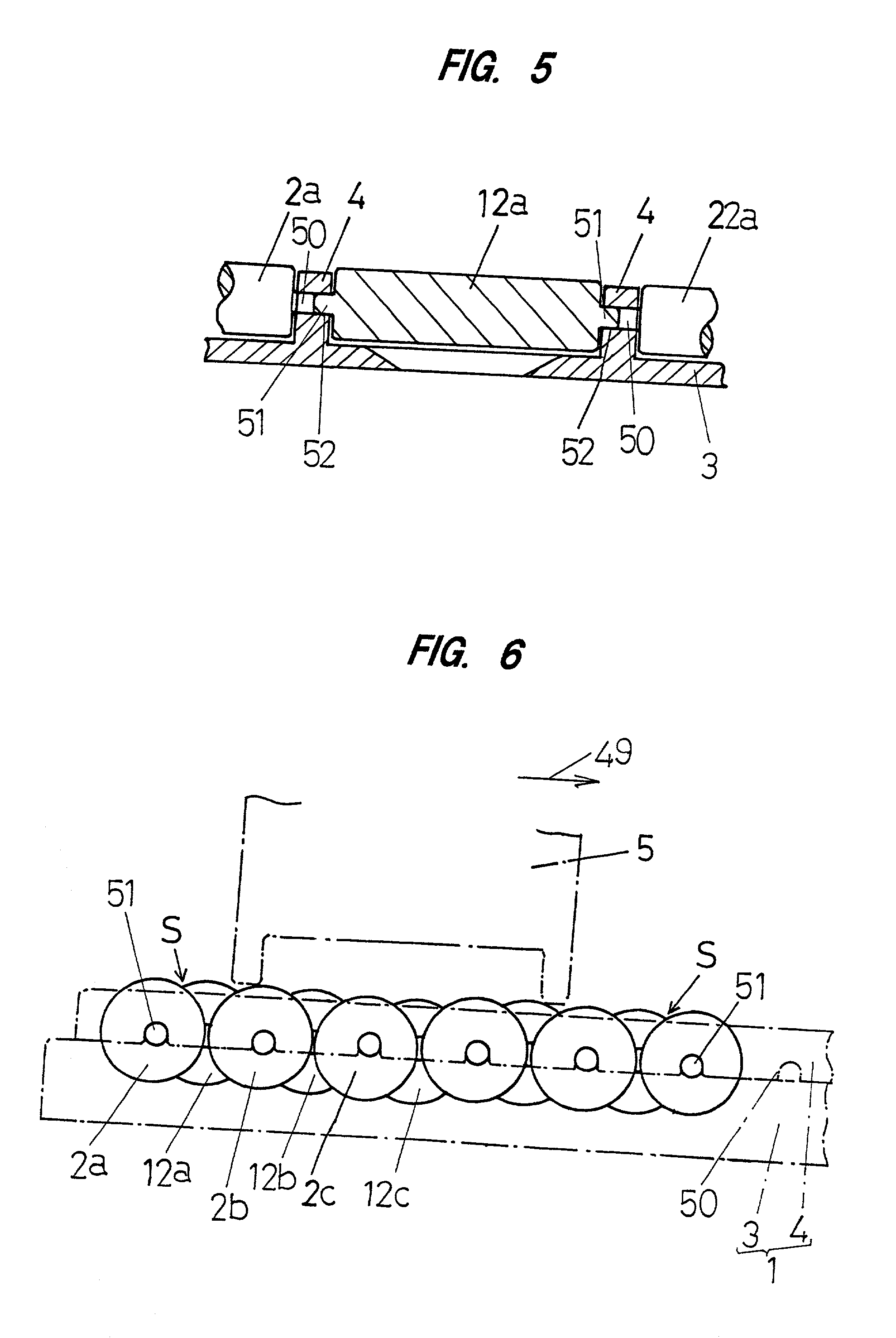

[0056] Referring to FIGS. 1 through 6, the embodiments of the present invention are now described in further details.

[0057] Referring first to FIG. 1, there is shown a showcase assembly unit for the showcase structure according to the present invention, which includes a roller support frame 1 and a plurality of parallel sets of rollers 2a to 2d, etc., 12a to 12d, etc., 22a to 22c, etc., 32a to 32c, etc. that are mounted on the roller support frame 1. The rollers in each set of rollers being mounted rotatably on the roller support frame 1 and arranged one after another from the rear end toward the front end of the roller support frame 1 and in parallel with each adjacent sets A, B, C and D.

[0058] More specifically, the parallel sets of rollers includes four sets of rollers A, B, C, and D, for example, that are arranged in parallel with each other in the direction perpendicular to the direction of the roller support frame 1 from the rear end toward the front end. Each of the sets A, B...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com