Multi-channel half-dry sludge switching device and sludge conveying system comprising same

A semi-dry sludge and switching device technology, applied in the direction of conveyor objects, slideways, transportation and packaging, etc., can solve the problems of difficult maintenance, increased cost, and inconvenient switching, so as to achieve smooth sludge feeding and improve work efficiency , to achieve the effect of self-cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

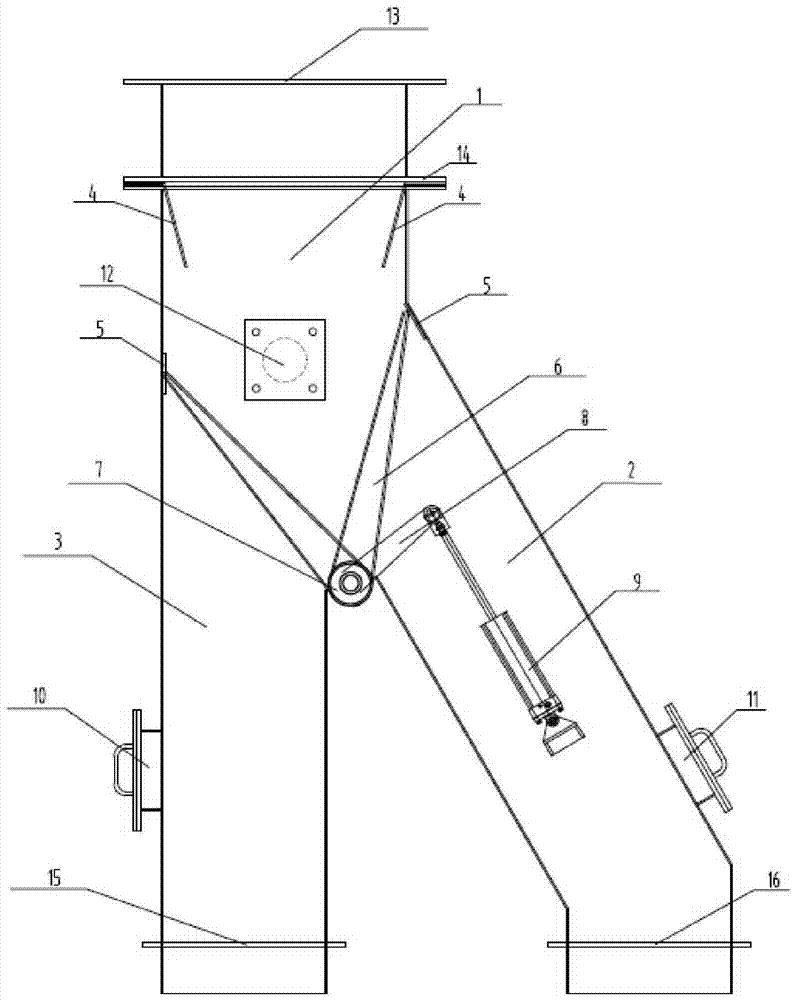

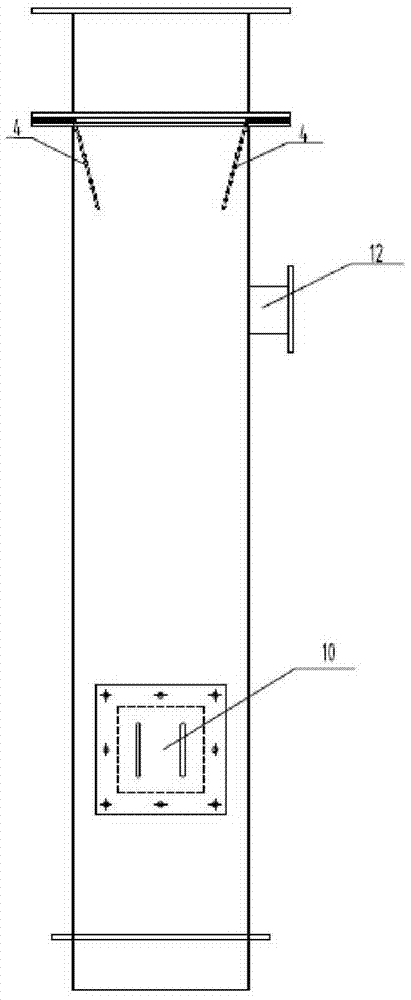

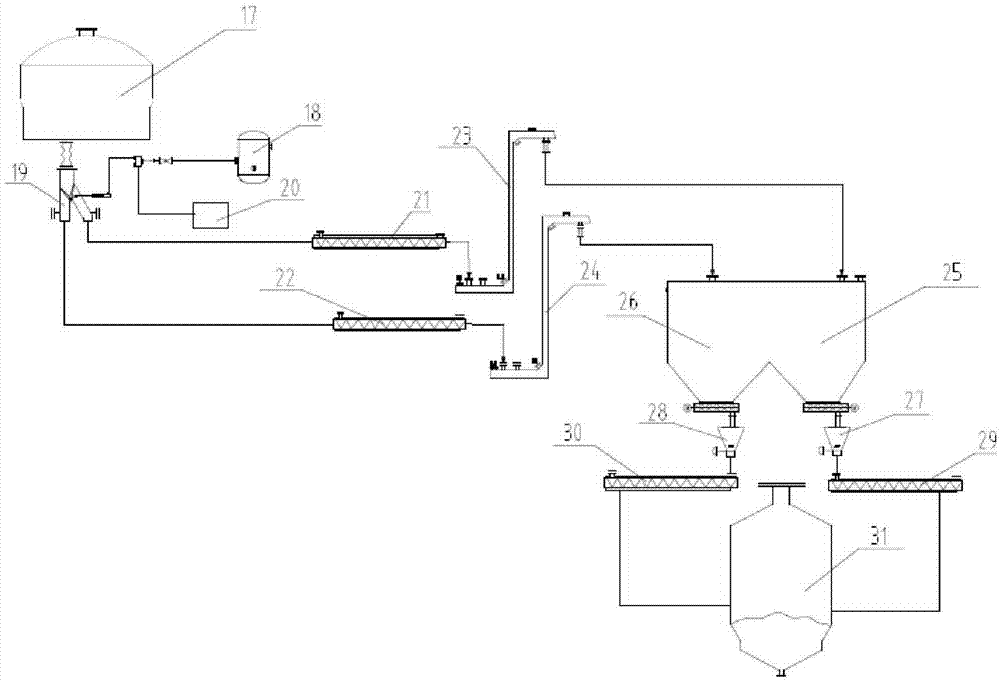

[0025] like figure 1 The shown multi-channel semi-dry sludge switching device includes a main channel 1 for sludge feeding, a first channel 2, a second channel 3, a deflector 4, a deflector splint 14, a buffer plate 5, a turning Plate 6, rotary shaft 7, connecting rod 8, power cylinder 9, inspection port A10, inspection port B11, bracket support 12, and connecting flanges (13, 15, 16); where:

[0026] The rotary shaft 7 is fixedly connected to the junction of the first channel 2 and the second channel 3, and a power cylinder 9 is connected to the outside of the first channel 2, and the selection of the power cylinder 9 is determined by calculating the stroke thrust and pulling force. The power cylinder 9 is connected with the rotary shaft 7 through the connecting rod 8, the rotary shaft 7 is fixed with the flap 6 (i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com