PP or PET spunbond spunlace non-woven fabric splitting machine

A spunbond spunlace and non-woven technology, applied in textiles and papermaking, cutting of textile materials, etc., can solve the problems of non-woven raw material feeding, affecting environmental quality, debris falling, etc., to improve environmental quality , to ensure the filtering effect, the effect of easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

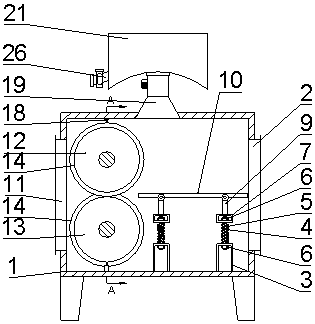

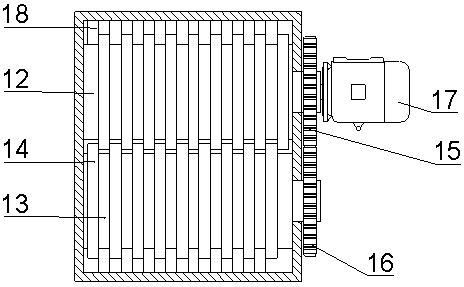

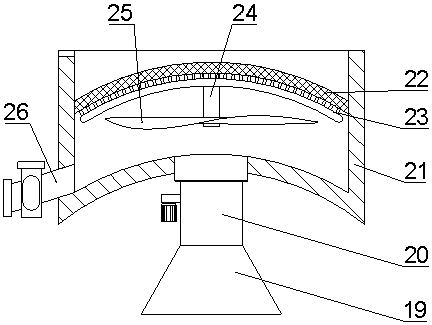

[0022] see Figure 1-3 , a PP or PET spunbond spunlace non-woven fabric slitting machine, comprising a slitting box 1, the left side wall of the slitting box 1 is provided with a feed port 2, and the right side wall of the slitting box is opened There is a discharge port 11, and the lower inner wall of the cutting box 1 close to the feed port 2 is fixedly connected with a fixed frame 3, and the fixed frame 3 is movable through a threaded post 4, and a compression spring 5 is sleeved on the threaded post. The other end of 4 is movable through a movable frame 7, the two ends of the threaded column 4 are screwed with adjusting nuts 6 respectively, the movable frame 7 is fixedly connected with a fixed rod 9, and the upper part of the fixed rod 9 is connected with a Sliding material plate 10, the inside left side of described slitting box 1 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com