Light-load AGV suspension adjusting device and working method

A technology of suspension device and adjustment device, applied in suspension, elastic suspension, transportation and packaging, etc., can solve the problems of large driving force of driving wheel, slipping or hanging of driving wheel, easy to slip or hanging in the air, etc., and achieve adaptability The effect of strong and optimal suspension parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

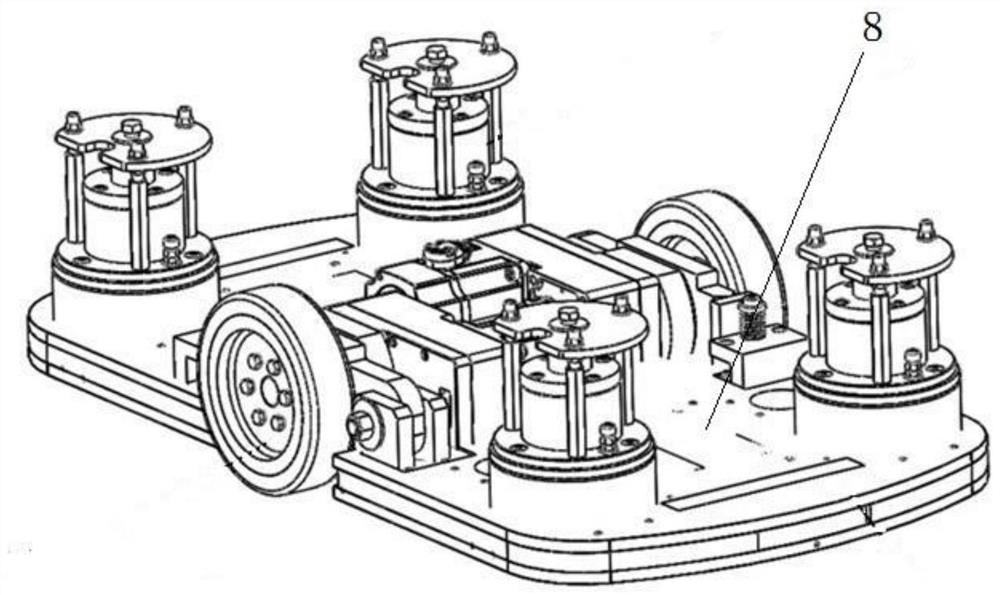

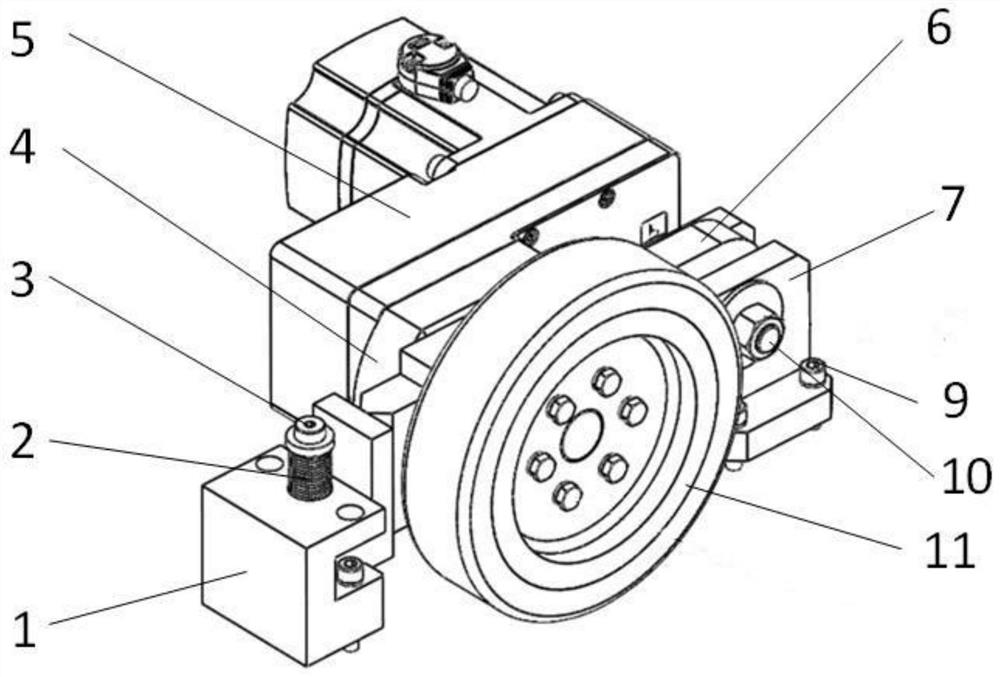

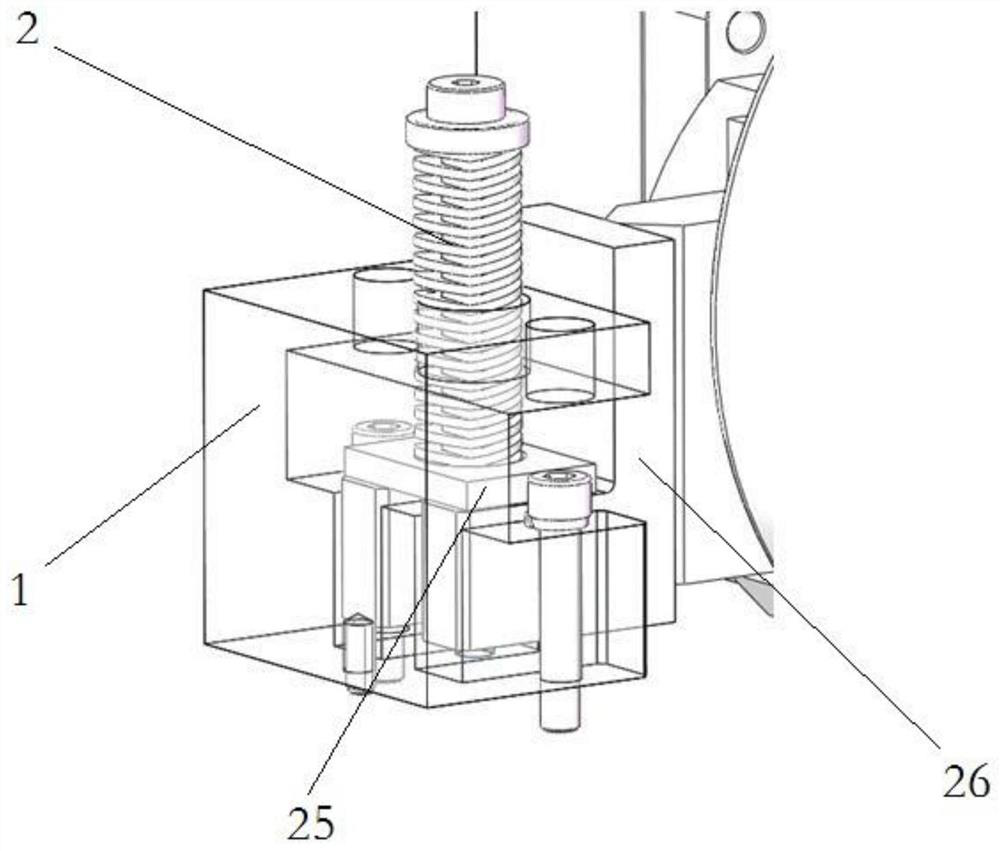

[0039]A suspension adjustment device for light-loaded AGVs, comprising an AGV base plate 8, a drive wheel suspension, and a universal wheel suspension; the AGV base 8 is provided with a universal wheel suspension, and the AGV base 8 is also provided with a drive wheel Suspension device, the number of driving wheel suspension devices is 2, the four corners of the AGV base plate 8 are provided with universal wheel suspension devices, two drive wheel suspension devices are arranged symmetrically at the center of the AGV base plate 8, and the drive suspension device includes a suspension bracket 1. The fork plate 26, the suspension bracket 1 is a horizontal "U" shape, the lower side of the suspension bracket 1 is provided with a board slot 28, and the fork board 26 is provided with a board compatible with the board slot 28 , the upper side of the board is provided with a fork plate cover plate 25, and the suspension bracket 1 is provided with a threaded hole 29, and the threaded ho...

Embodiment 2

[0041] A light-load AGV suspension adjustment device is different from Embodiment 1 in that there are two universal wheel suspension devices, which can be arranged symmetrically along the center line.

Embodiment 3

[0043] A working method for a light-load AGV suspension adjustment device, the structure of which is as in embodiment 1 includes the following steps:

[0044] Install the driving wheel suspension device and the universal wheel suspension device on the AGV base plate 8 according to actual needs, and conduct a trial run first, and drive the entire AGV trolley to move through the driving motor. The bracket moves up and down, and the spring stretches to support the shock absorber, so that the shock absorber moves around the pin shaft in a small scale. After running for a certain distance, adjust the adjustment nut up and down according to the shock absorption during the movement of the AGV trolley. , including the adjustment nuts for the universal wheel and the driving wheel to achieve the best shock absorption effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com