Full-automatic non-woven fabric shoe cover overlock machine

A fully automatic and overlocking machine technology, which is applied in the direction of shoemaking machinery, footwear, repairing machines, etc., can solve the problems of long shoe cover travel, plastic film material tearing, easy to generate static electricity, etc., to achieve a smart structure design, The effect of small space occupation and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Below in conjunction with accompanying drawing, the implementation of technical scheme is described in further detail:

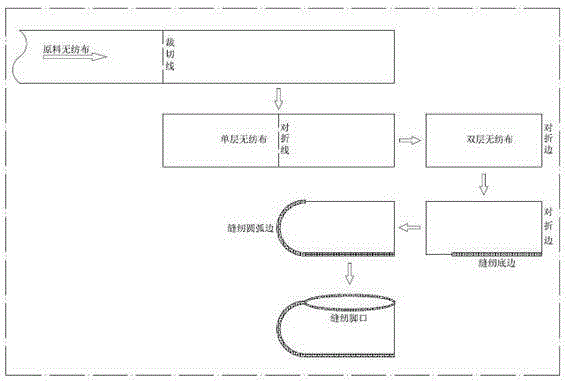

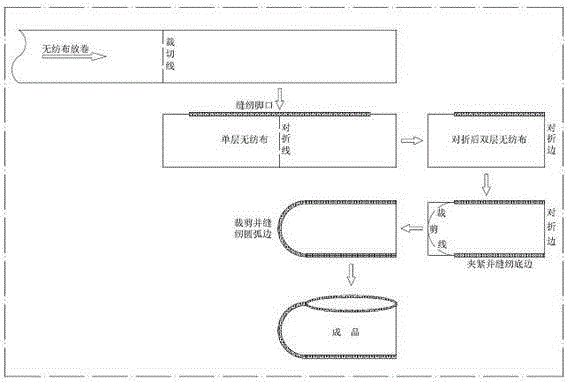

[0049] Such as figure 2 As shown, it is the production flow chart of the shoe cover of the present invention. Since the opening of the shoe cover is difficult to be automatically opened by mechanical equipment and then sewed a whole circle after folding, considering that the opening of the shoe cover is a straight line after being unfolded, the device of the present invention The general manual sewing sequence is reversed: first use the No. 1 seaming machine to sew the shoe cover opening, then fold and cut it, then use the No. 2 seaming machine to sew the sole mouth, and finally the clamp device is rotated by the No. 2 seam Machine sew arcs and cut arc edges to make more parts.

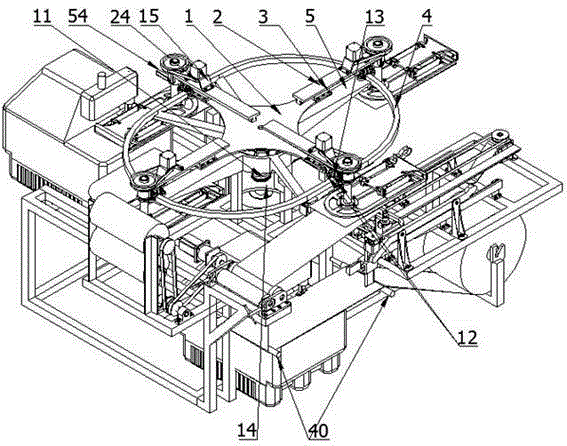

[0050] see image 3 , The fully automatic non-woven shoe cover edge press machine of the embodiment of the present invention includes a central cross rotating device, a gu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com