Fixture for non-woven fabric automatic sewing shoe cover machine

The technology of a non-woven fabric and shoe cover machine is applied in the field of clamps driven by elastic potential energy and external force, and non-woven clamps. Achieve the effect of improving bending fatigue strength and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The implementation of the technical solution will be further described in detail below in conjunction with the drawings:

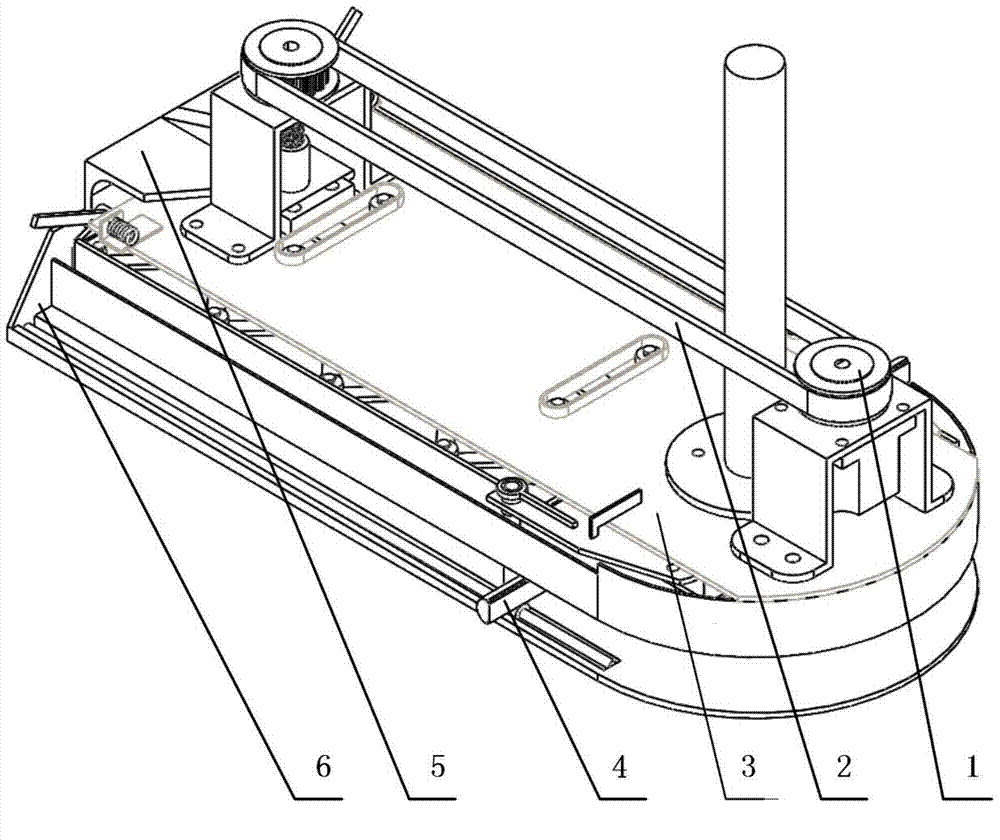

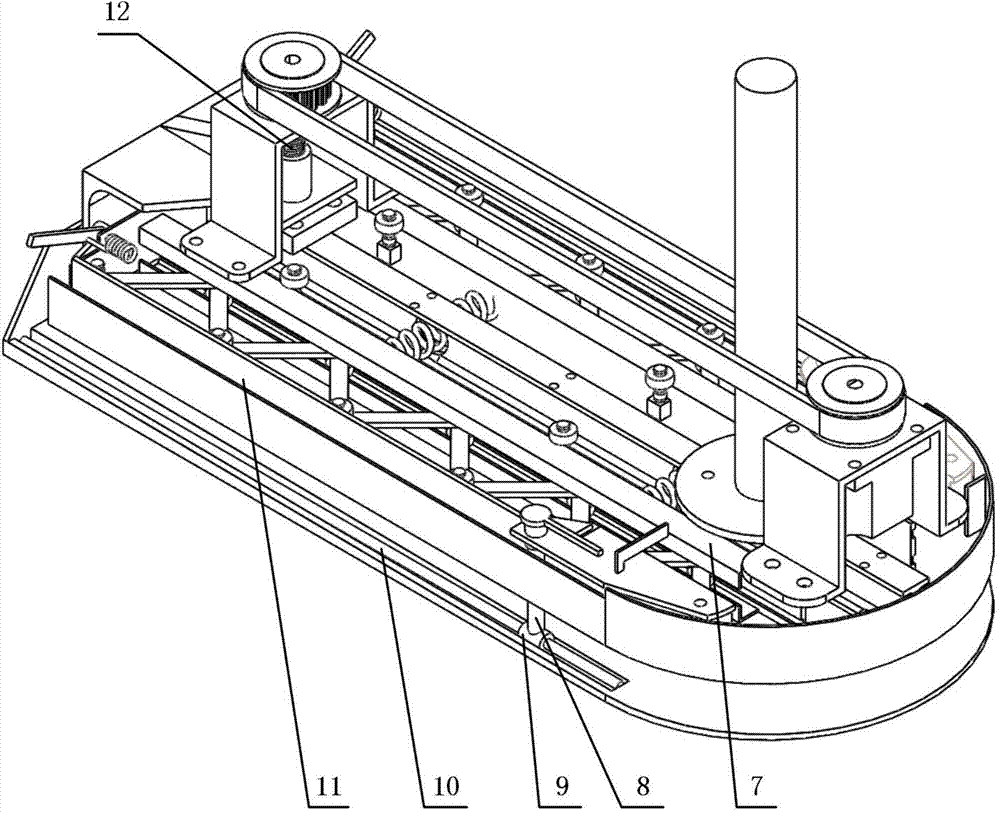

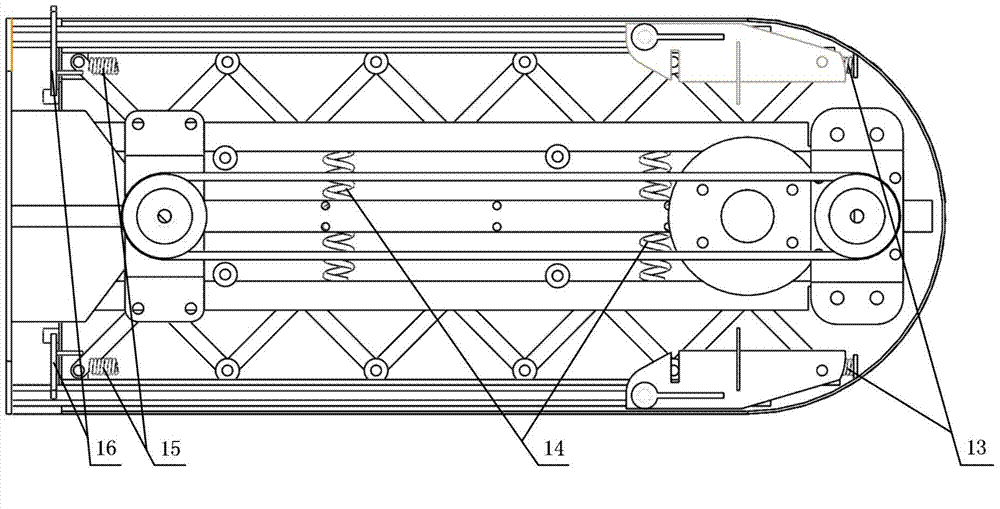

[0031] Such as figure 1 As shown, the clamp for the non-woven automatic sewing shoe cover machine of the present invention adopts a method of combining the folding process with the movement of the clamp, and includes a timing belt transmission mechanism, a threaded transmission lifting mechanism, a folding mechanism, a connecting mechanism, a self-locking mechanism, The upper clamping plate 3 and the lower clamping plate 6 of the clamp, the timing belt transmission mechanism and the threaded transmission lifting mechanism are arranged on the upper clamping plate 3, the folding mechanism is arranged inside the upper clamping plate 3, the self-locking mechanism is arranged behind the upper clamping plate 3, and the connecting mechanism is arranged on the clamp On both sides, the upper splint 3 and the lower splint 6 are connected. Between the upper splint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com