Paperboard collecting machine

A technology of cardboard and crossbar, which is applied in the direction of stacking receiving device, sending objects, thin material processing, etc. It can solve the problems of over-tight conveyor belt, high maintenance and maintenance costs, and different lengths.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

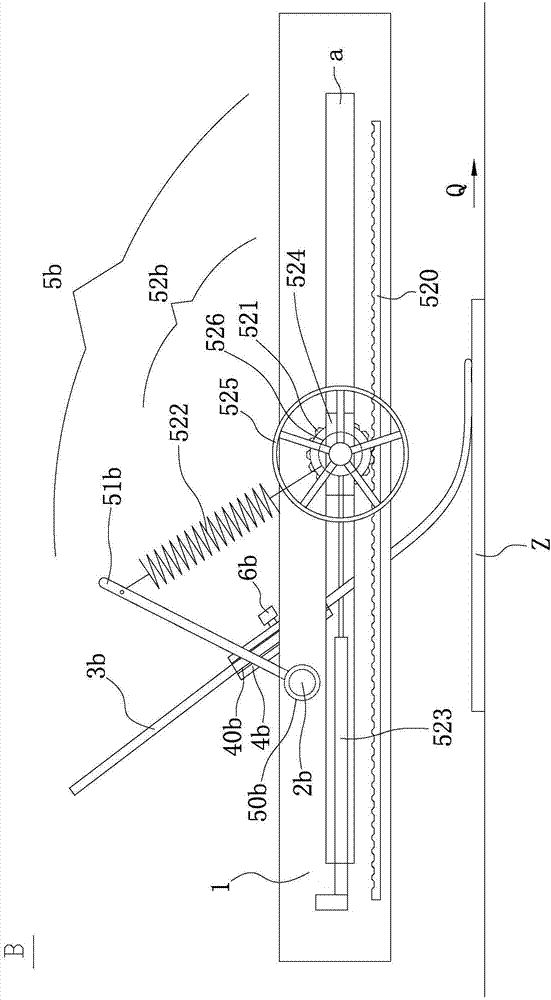

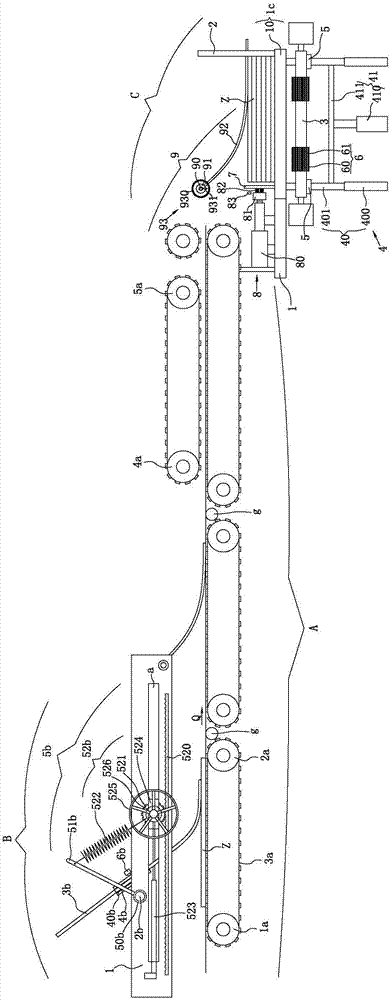

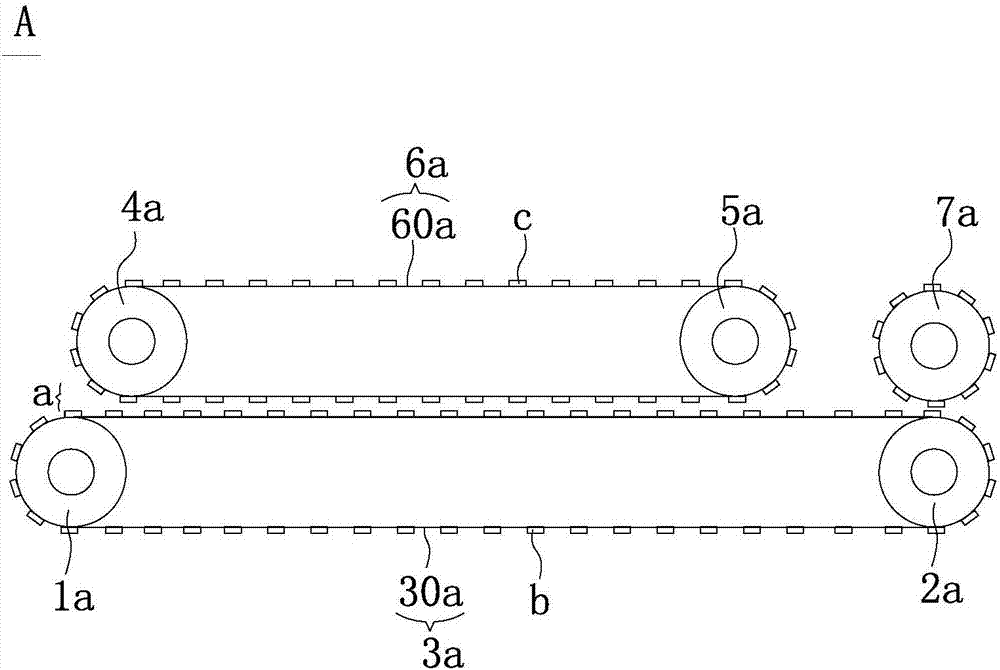

[0075] Such as Figure 1 to Figure 7 As shown, the cardboard collecting machine provided in this embodiment includes a collecting frame 1; a conveying device A, including a plurality of conveying units successively connected along the conveying direction of the cardboard; a counting device, which is used to count the number of cardboards after cutting; Pressing device B; stacking device C; central control system; at least one of the multiple conveying units can be set to be accelerated instantaneously. Continuously cut cardboard is set in batches in the transfer unit.

[0076] In this example, there are three transmission units (from left to right), and the three transmission units are connected by the receiving roller g rotating around its own axis. The transmission unit in the middle (the second transmission unit) can be set up instantly, and there are pressing devices on the first and second transmission units (in order to see the specific structure, the attached figure 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com