Fixing and rust-removing equipment for steel tubes of different tube diameters

A steel pipe and equipment technology, applied in the field of steel pipe fixed derusting equipment, can solve the problems of steel pipes of different specifications clamping, high labor intensity of operation, cumbersome derusting work, etc., and achieve the effect of reducing workload and improving grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

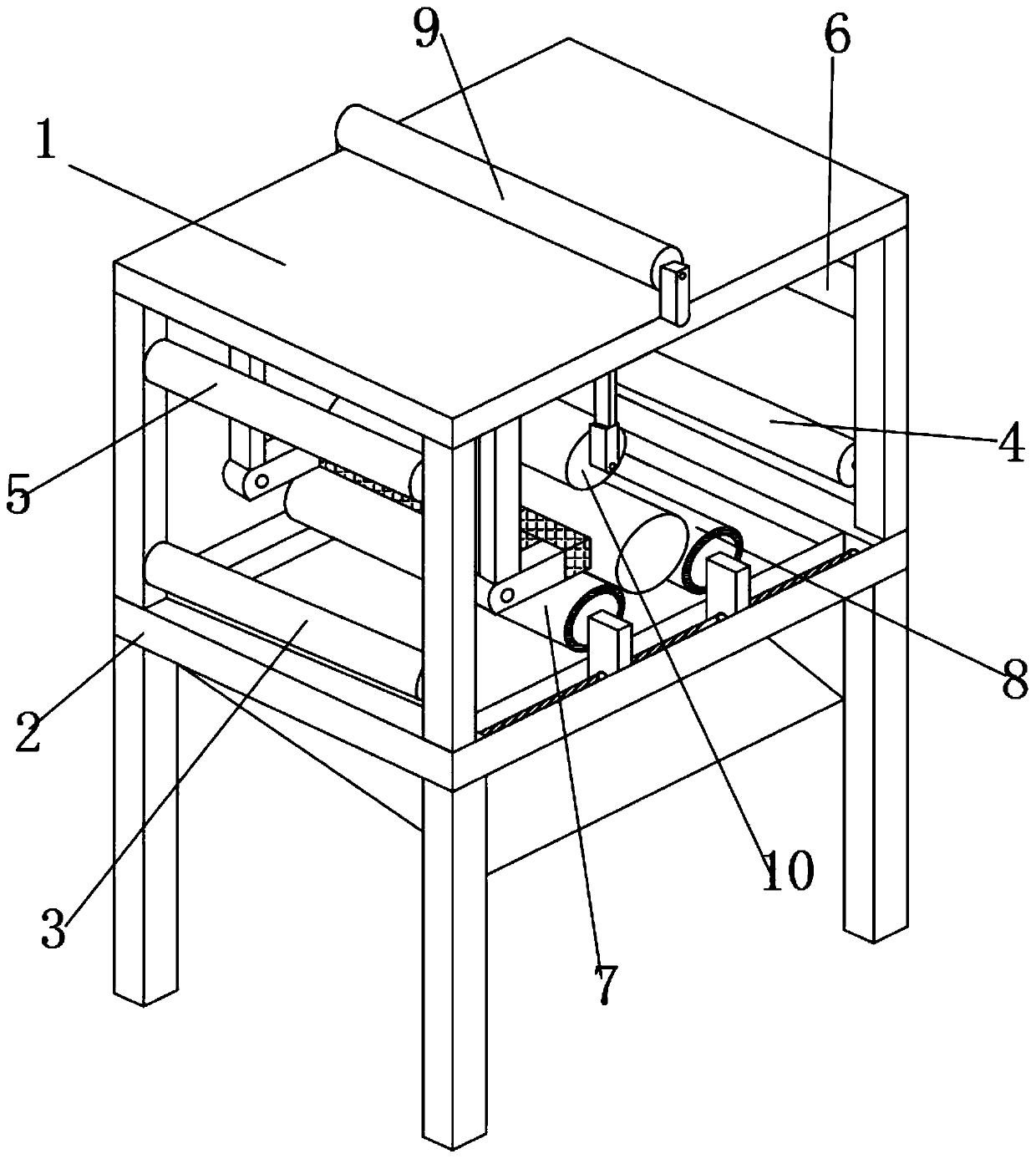

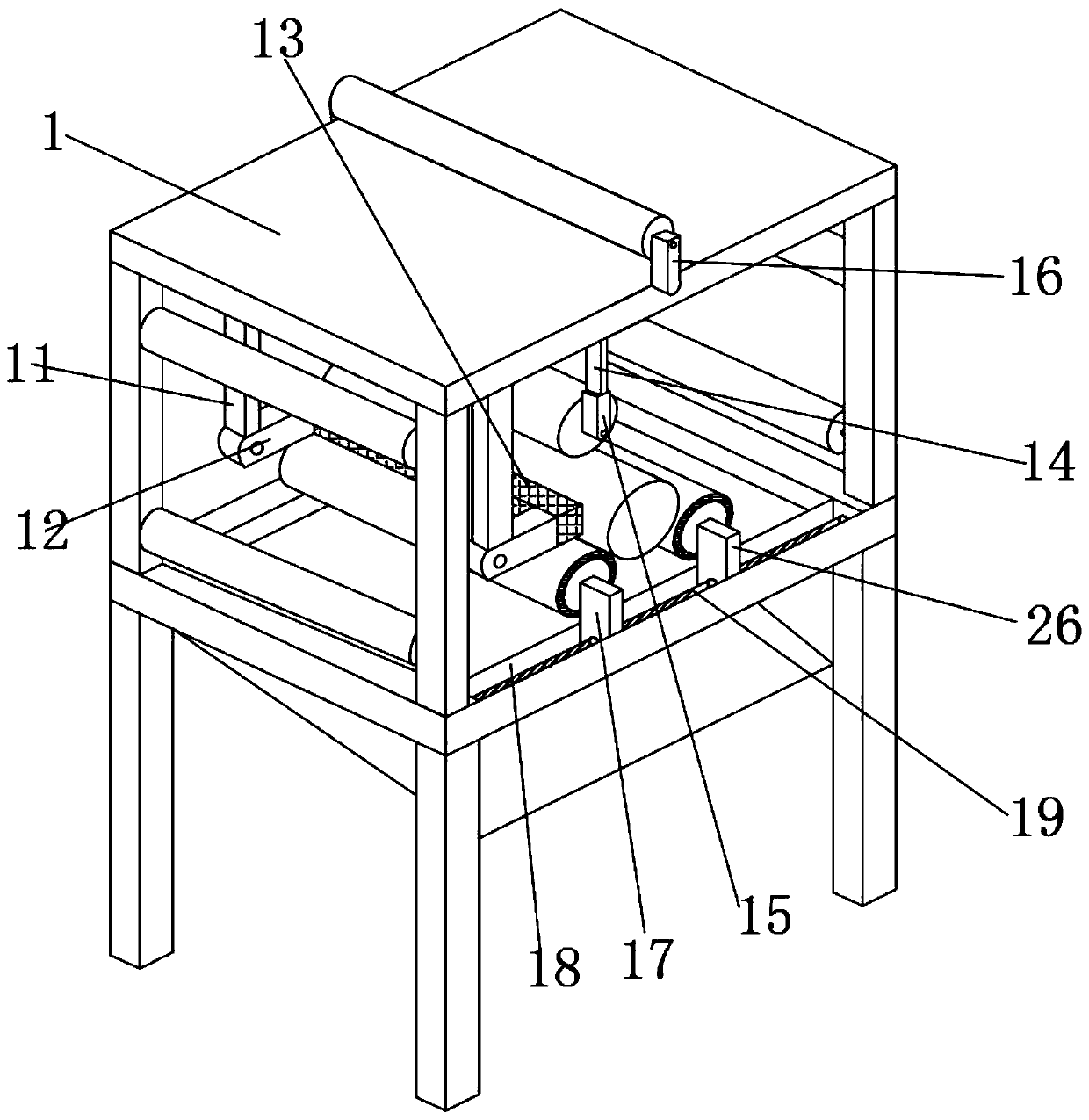

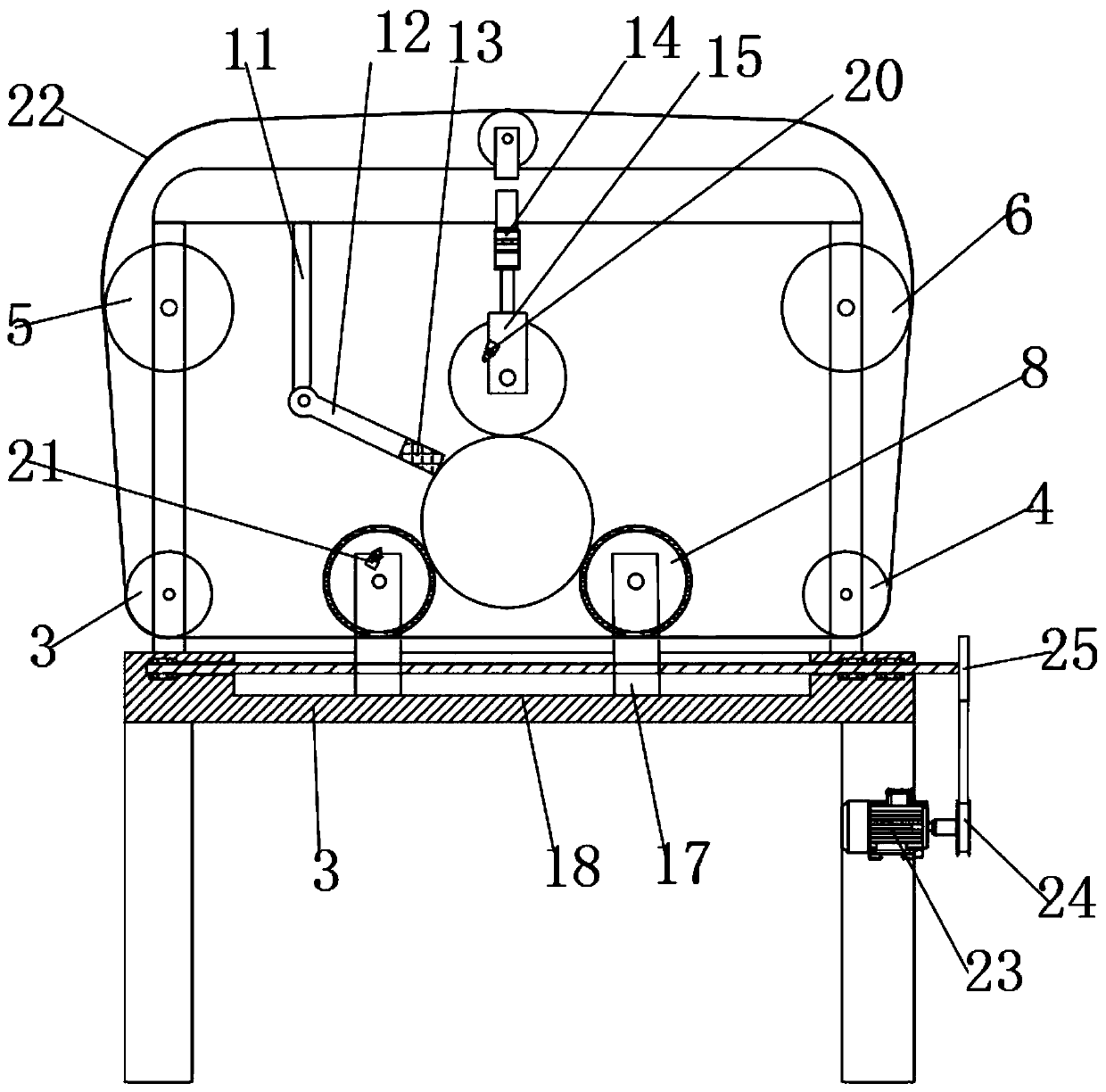

[0023] Example: see Figure 1-3 , the present invention provides a technical solution: a fixed derusting equipment for steel pipes with different pipe diameters, which includes a triangular clamping assembly, a driving assembly, and a grinding and derusting assembly, the triangular clamping assembly includes a bottom support adjustment assembly and The top pressing assembly, the bottom support adjustment assembly and the top pressing assembly can adjust the position according to the diameter of the steel pipe to clamp the steel pipe in a triangular shape, and the driving assembly is used to drive the roller body in the triangular clamping assembly to rotate, thereby The steel pipe is driven to rotate, and the grinding and derusting assembly is arranged on one side of the triangular clamping assembly so as to polish the surface of the steel pipe.

[0024] In this embodiment, the bottom support adjustment assembly is arranged on the support base 2, and the support base 2 is form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com