Stick-slip driving cross-scale precise motion platform

A precision motion and cross-scale technology, which is applied in the direction of generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc. Limitation, complex manufacturing process and other issues to achieve the effect of ensuring motion accuracy and consistency, facilitating processing and assembly, and simplifying adjustment methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

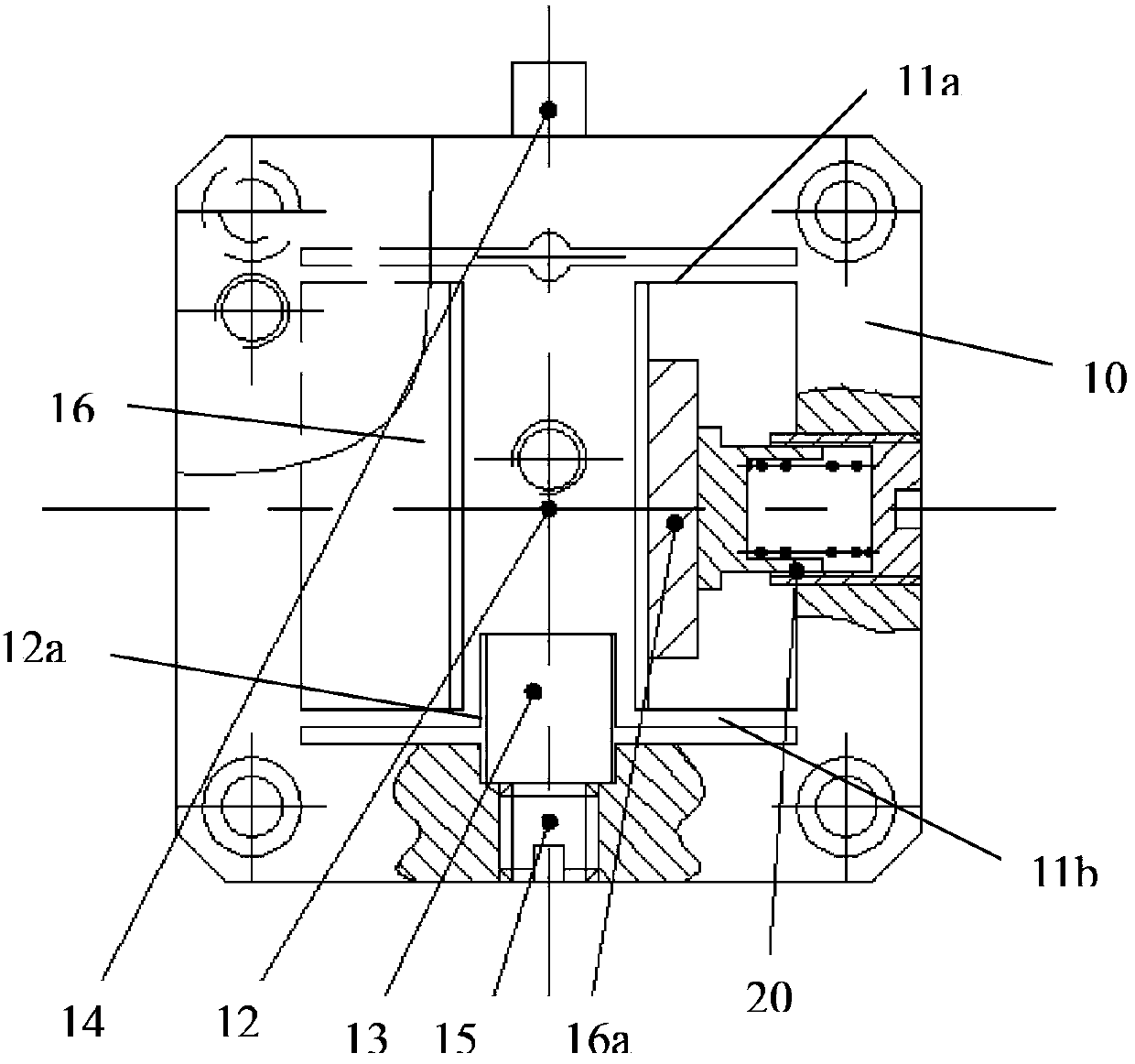

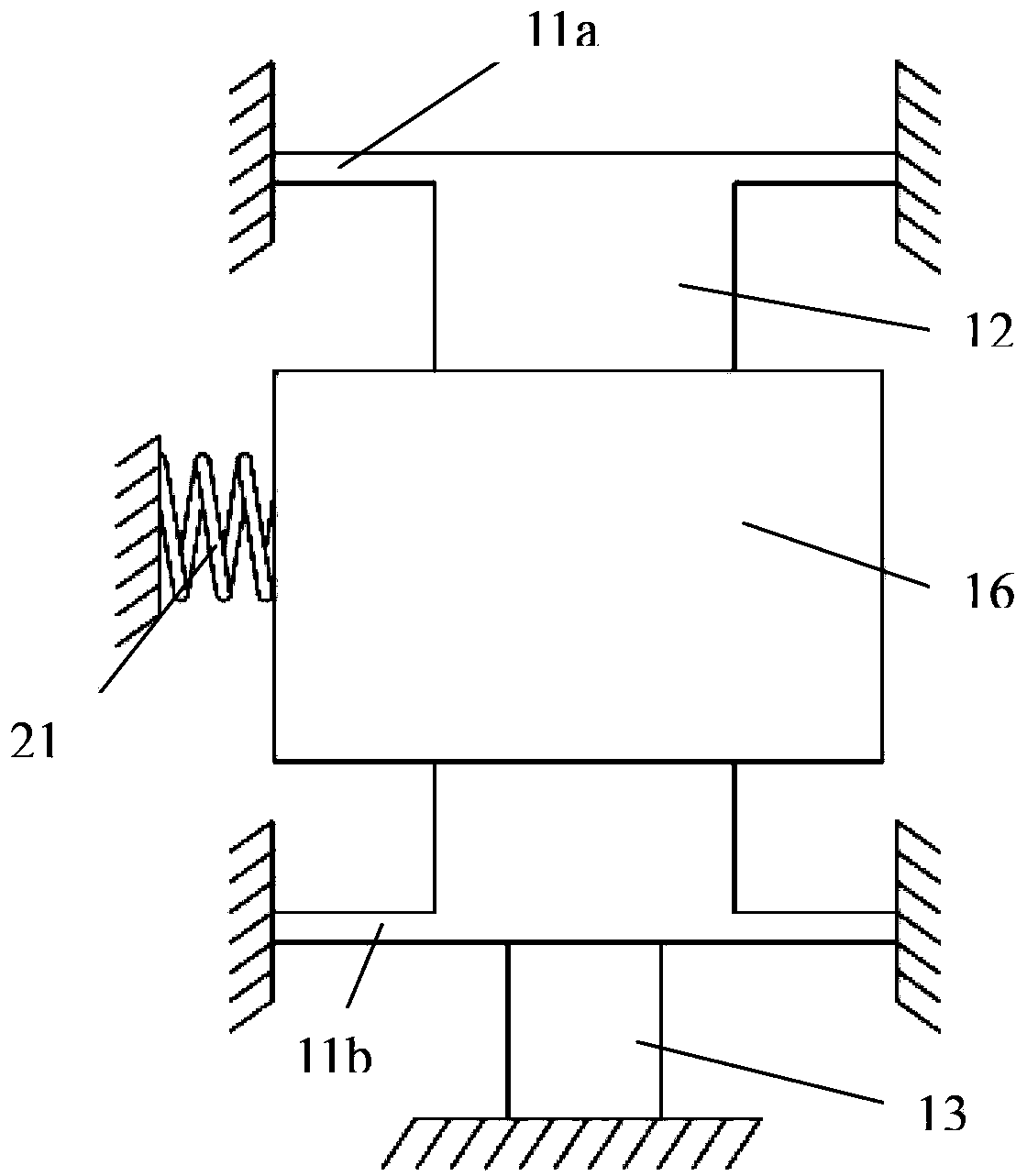

[0035] The embodiment of the present invention discloses a stick-slip driving cross-scale precision motion platform, including:

[0036] base;

[0037] The friction vibrator is installed on the base;

[0038] The driving source of the vibrator, the driving source of the vibrator is installed between the friction vibrator and the base, and provides driving force to the friction vibrator. Preferably, the relationship between the driving force and time is in the shape of a sawtooth wave;

[0039] The slider is sleeved on the friction vibrator, and is in contact with the friction vibrator to generate friction;

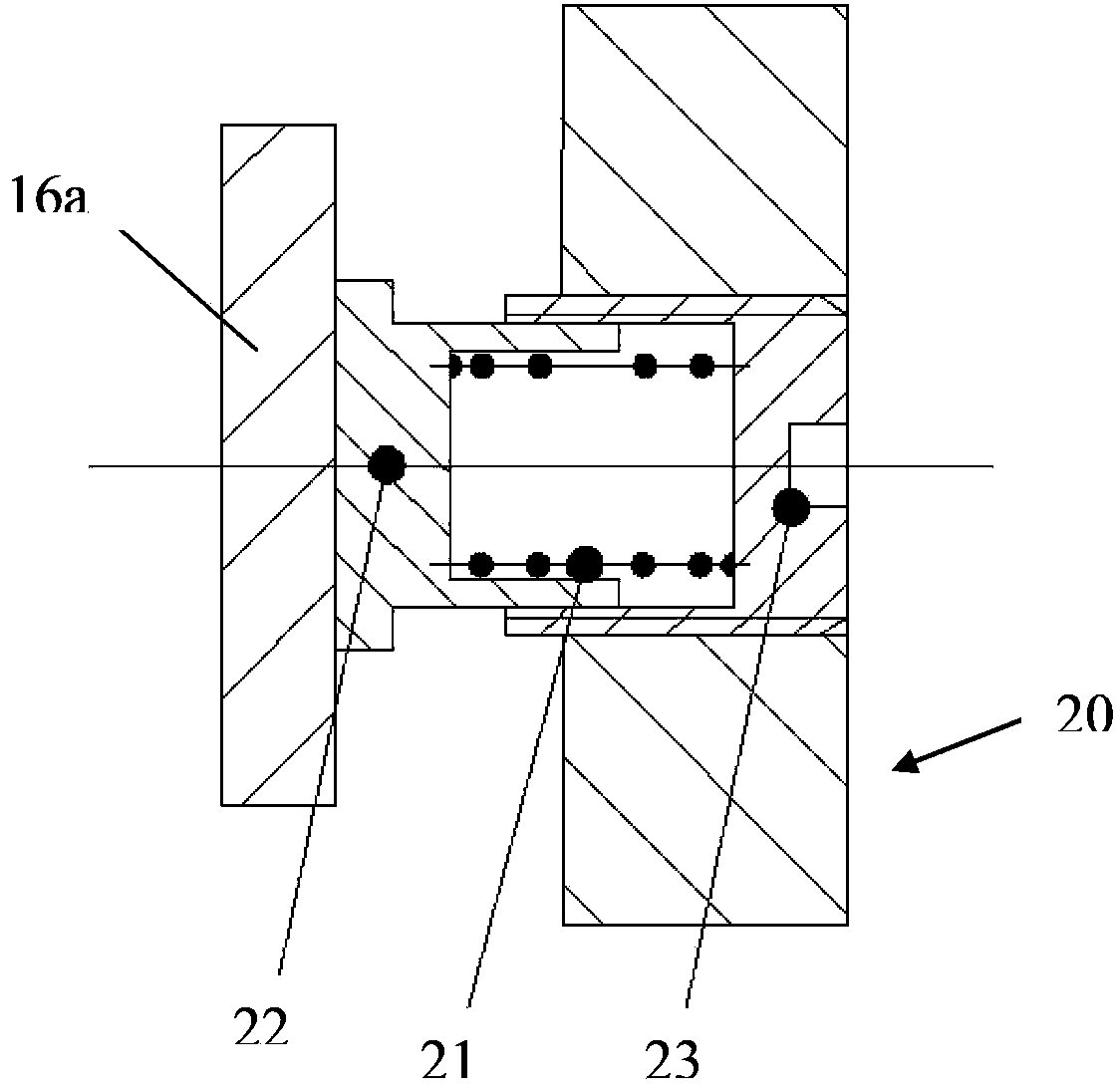

[0040] Among them, a pre-tightening force adjustment structure providing pre-tightening force is provided between the side of the slider and the base, which is used to adjust the friction force. A stick-slip effect is generated between the slider and the friction vibrator, and the slider performs cross-scale precision movement.

[0041] Preferably, the pre-tight force adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com