Round timber pier slitting equipment

A technology for cutting strips and wooden piers is applied in the field of circular wooden pier cutting equipment, which can solve the problems of inconvenient cleaning of debris and achieve the effect of convenient cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

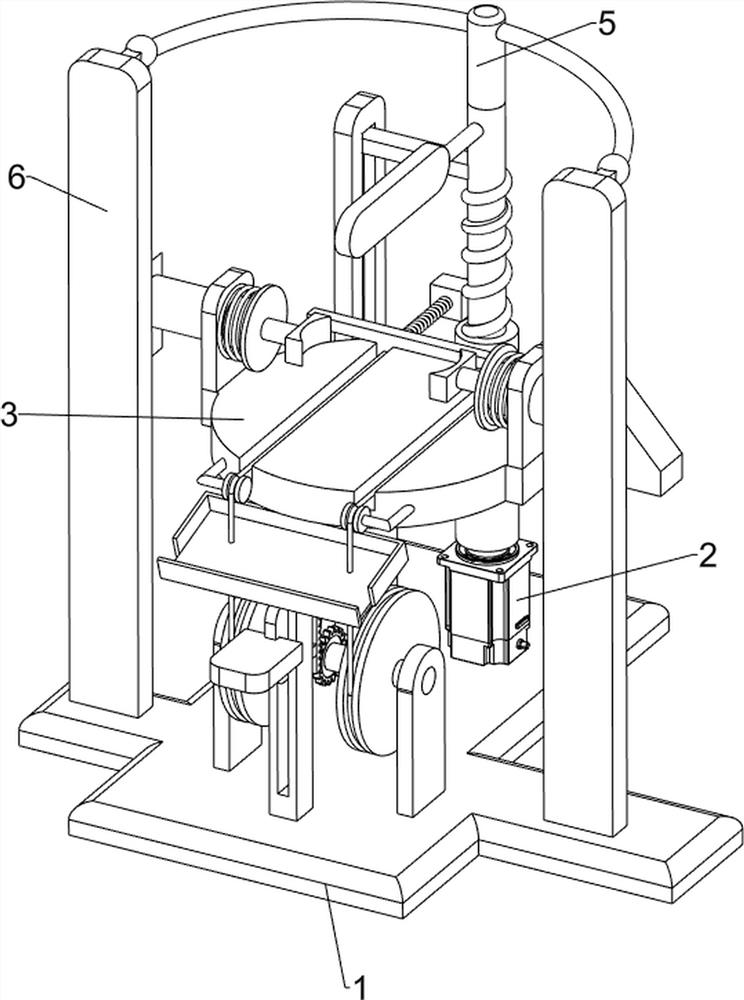

[0022] A kind of round wooden pier cutting equipment, such as figure 1 As shown, it includes a base 1, a servo motor 2, a workbench 3, a support rod 4, a strip cutting mechanism 5 and a clamping mechanism 6, a servo motor 2 is provided on the rear side of the top of the base 1, and a support rod 4 is provided in the middle of the top of the base 1 , the top of the support rod 4 is provided with a workbench 3, and the rear side of the top of the base 1 is provided with a cutting mechanism 5. Mechanism 6, the parts of the clamping mechanism 6 are connected with the parts of the strip cutting mechanism 5.

[0023] When people need to cut a circular wooden pier, they first place the circular wooden pier in the middle of the workbench 3, then start the parts of the strip cutting mechanism 5, and then people start the servo motor 2 to rotate forward, and the output of the servo motor 2 The forward rotation of the shaft drives the parts of the strip cutting mechanism 5 to rotate, an...

Embodiment 2

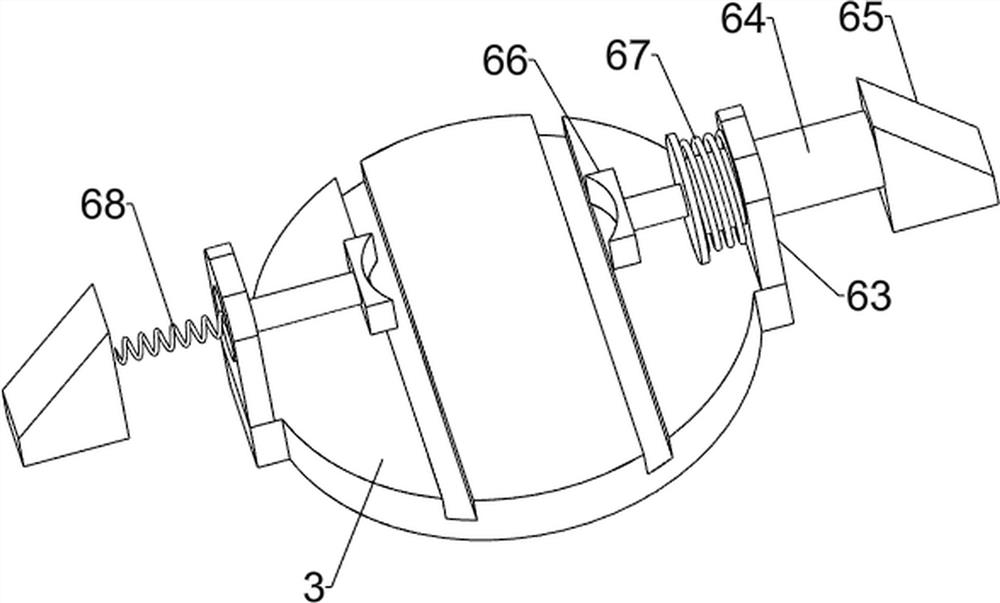

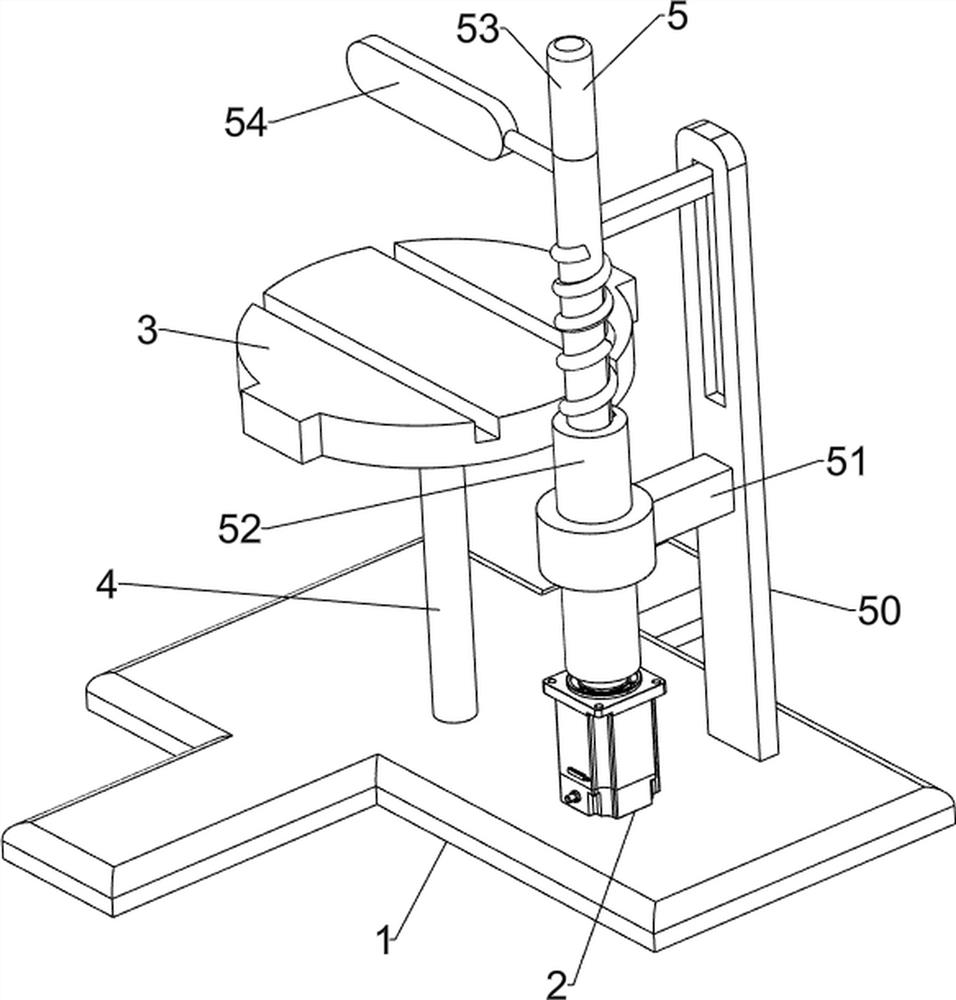

[0025] On the basis of Example 1, such as Figure 2 to Figure 4 As shown, the strip cutting mechanism 5 includes a first slide plate 50, a rotary sleeve 51, a screw sleeve 52, a screw rod 53 and a small electric saw 54, and the left rear side of the top of the base 1 is provided with the first slide plate 50, and the middle of the right part of the first slide plate 50 The side is provided with a rotary sleeve 51, and the internal rotation of the rotary sleeve 51 is provided with a screw sleeve 52, the screw sleeve 52 is connected with the output shaft of the servo motor 2, and the screw sleeve 52 is internally threaded to be connected with a screw rod 53, and the screw rod 53 slides with the first slide plate 50 Type is connected, and screw rod 53 upper side fronts are provided with small electric saw 54.

[0026] When people need to cut a circular wooden pier, they place the circular wooden pier in the middle of the top of the workbench 3, and they first start the servo moto...

Embodiment 3

[0030] On the basis of Example 2, such as Figure 5 and Figure 6 Shown, also include fixed rod 7, push plate 8, second spring 9, small reel 10, fixed seat 11, rotating shaft 12, large reel 13, collection frame 14, stay cord 15, guide rail 16, slide Rack 17, gear 18 and pedal 19, base 1 rear side, top, left and right sides are all provided with fixed rod 7, workbench 3 top is slidingly connected with push plate 8, and push plate 8 rear part is all connected with fixed rod 7 There is a second spring 9, a small winding wheel 10 is provided on the left and right sides of the front of the workbench 3, and a fixed seat 11 is arranged on the left and right sides of the top of the front side of the base 1, and a rotating shaft is connected between the upper side of the fixed seat 11 12, the left and right sides of the rotating shaft 12 are provided with a large reel 13, the left and right sides of the front of the push plate 8 and the large reel 13 are connected with a stay cord 15,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com