Maintenance-assistant device with liftable and overturning circuit breaker base plate

An overhaul device and a flip-up technology, which is applied to lifting devices, switch devices, electrical components, etc., can solve problems such as personal injury, damage, and maintenance personnel injury, and achieve the effects of good safety performance, strong operability, and convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

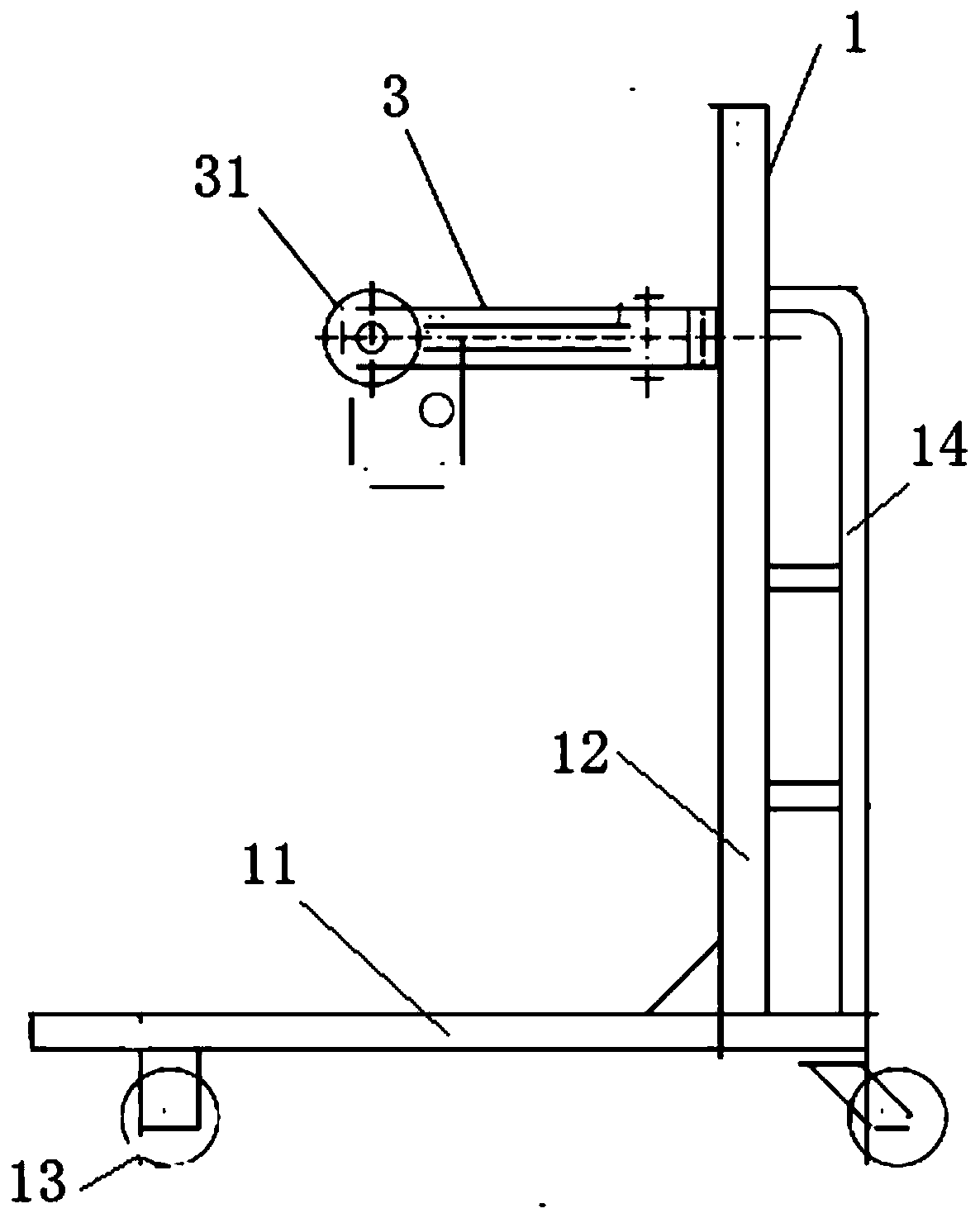

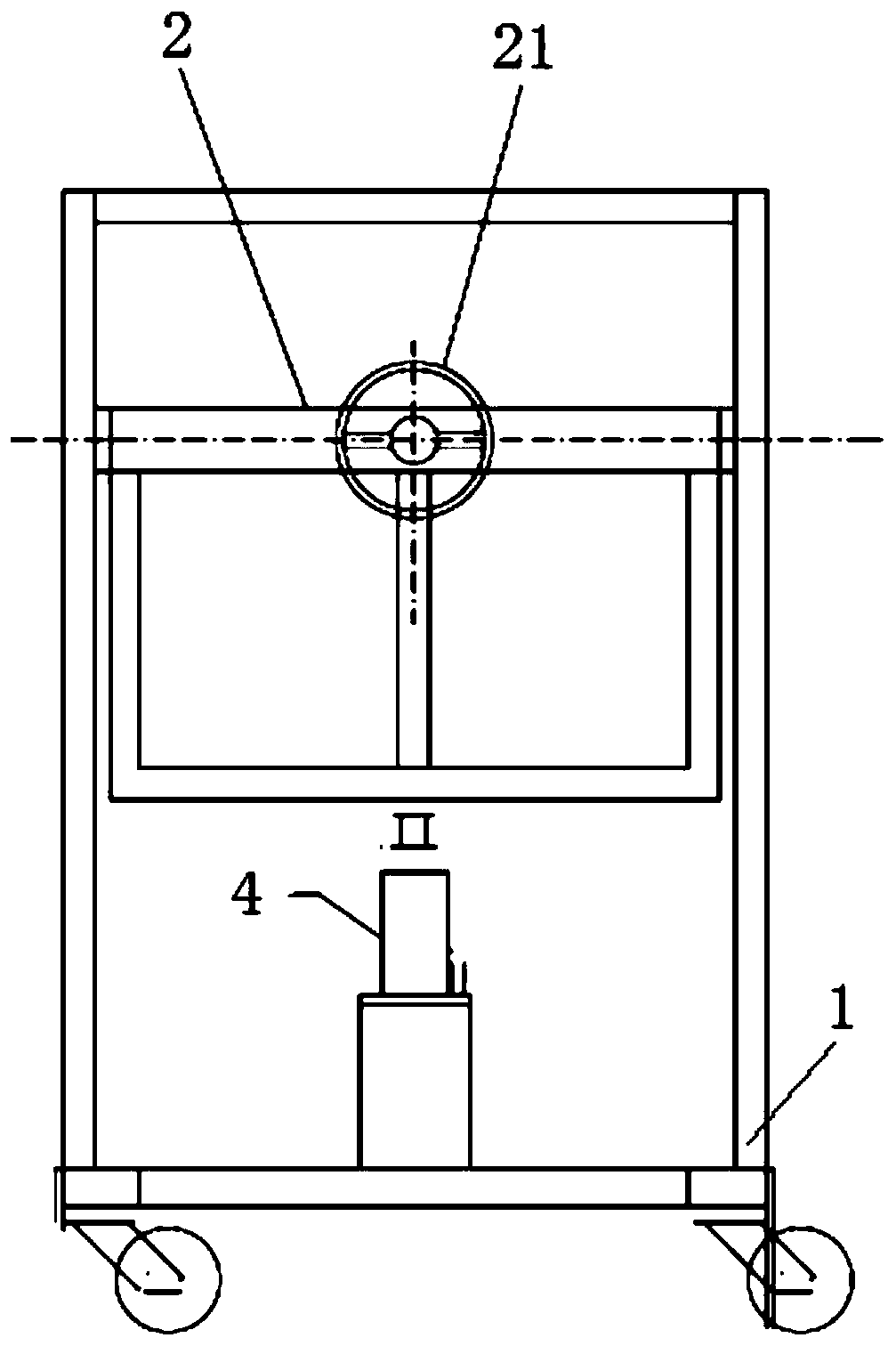

[0026] Such as figure 1 and figure 2 As shown, the maintenance device for the chassis of a 10 kV central cabinet vacuum circuit breaker includes a vehicle frame 1, a lifting bracket 2 that can be vertically lifted along the frame, a linear driver for driving the lifting bracket to go up and down, and is installed on the left and right sides of the lifting bracket And the two clamping arms 3 that extend forward, the overturn bracket 31 that is hinged on the inner side of the front end of the clamping arm, the two clamping arms are connected with the opening and closing control structure that controls opening and closing, and the four corners of the bottom of the vehicle frame are provided with There are wheels 13, a linear guide rail is provided between the lifting bracket and the vehicle frame, the turning bracket is fixed with a vacuum circuit breaker, and the turning bracket is connected with an angle positioning structure for fixing the angle of the turning bracket.

[00...

Embodiment 2

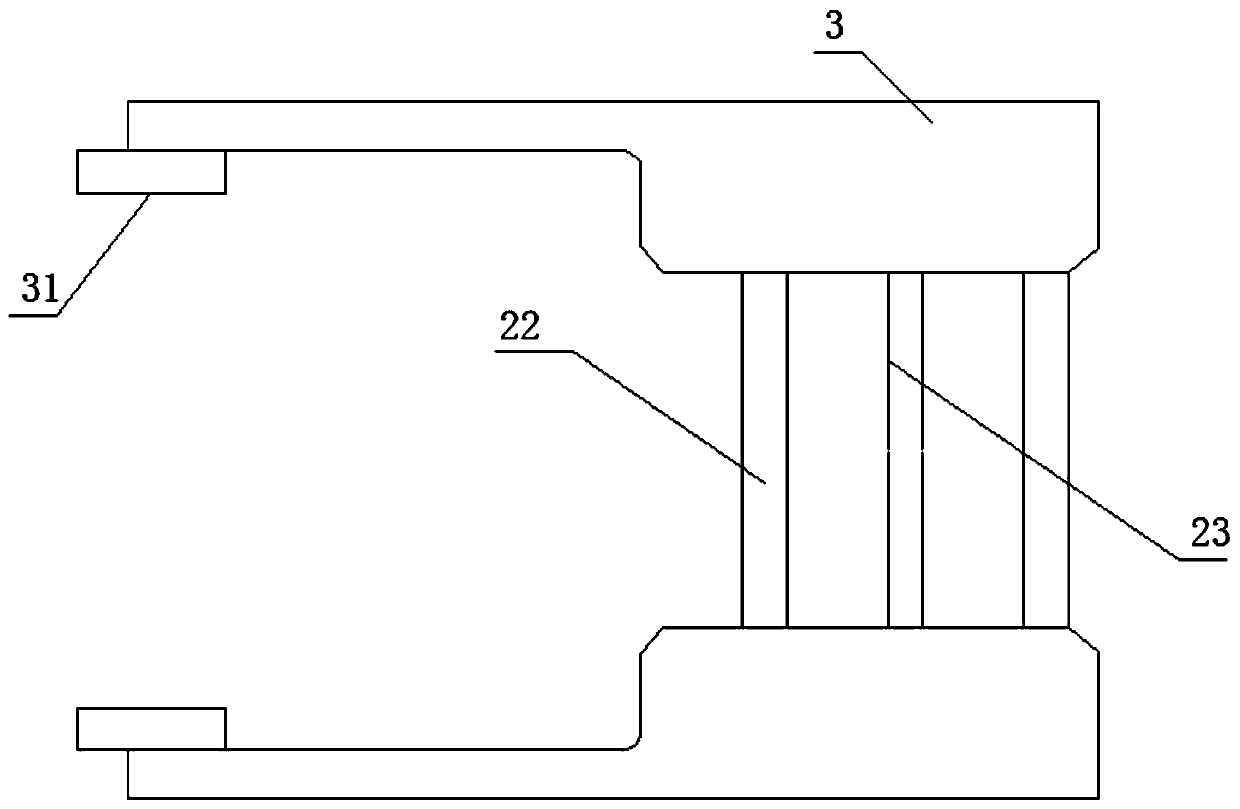

[0032] refer to image 3 As shown, the difference from Embodiment 1 is that the lifting bracket is provided with a transverse guide rail 22, and the transverse guide rail is connected to the clamping arm assembly, and the clamping arm assembly includes a left clamping arm and a right clamping arm separately arranged side by side. Side clamping arm, the front inner side of the left clamping arm and the right clamping arm hinge flip bracket 31, the left clamping arm and the right clamping arm are respectively connected to the horizontal ball wire by the left nut and the right nut Rod 23, the horizontal ball screw is connected with the clamping motor, the clamping motor drives the horizontal ball screw, the horizontal ball screw drives the left and right nuts to move, and the left and right nuts respectively drive the left clamping arm and the right clamping arm along the The horizontal guide rail moves, and the clamping arm is clamped by the motor drive, which is convenient for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com