Ultrasonic cleaning equipment with high safety

A technology for cleaning equipment and ultrasonic waves, which is applied in the directions of cleaning methods using liquids, cleaning methods and utensils, chemical instruments and methods, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

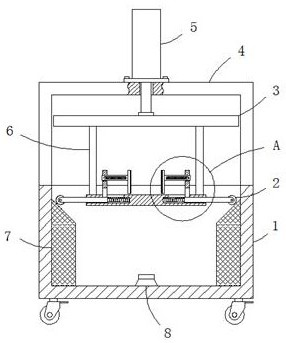

[0022] Example 1 as figure 1 As shown, this kind of high-safety ultrasonic cleaning equipment includes a box body 1 with an opening at the upper end. The baffle plate 3 matched with the opening of the U-shaped plate 4 is fixed with an electric push rod 5 in the upper middle of the horizontal part of the U-shaped plate 4. Fixedly connected, the inside of the opening of the box body 1 is provided with a horizontal supporting plate 9, and a vertical connecting plate 6 is symmetrically fixedly connected between the left and right sides of the upper end of the supporting plate 9 and the lower end of the baffle plate 3, and the inside of the box body 1 is located The left and right sides of the supporting plate 9 are symmetrically provided with rectangular blocks 7, and the side walls of the opposite sides of the two rectangular blocks 7 are fixedly connected with the inner side walls of the box body 1, and the opposite sides of the two rectangular blocks 7 The upper ends of the si...

Embodiment 2

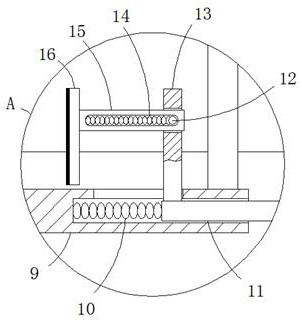

[0023] Embodiment 2 is on the basis of embodiment 1 such as figure 2 As shown, its moving mechanism includes a push rod 11 and a first spring 10, the rod wall of the push rod 11 is slidably connected with the hole wall of the blind hole, and one end of the push rod 11 extends to the outside of the blind hole and abuts against the inclined surface, the second Two ends of a spring 10 are respectively fixedly connected with one end of the push rod 11 located in the blind hole and the bottom of the blind hole, and the lower end of the movable plate 13 is fixedly connected with the upper side wall of the push rod 11 .

Embodiment 3

[0024] Embodiment 3 is such as on the basis of embodiment 1 figure 2 As shown, its clamping mechanism comprises movable rod 15, fixed rod 12, second spring 14 and splint 16, and the rod wall of movable rod 15 is slidably connected with the hole wall of slide hole, and the two ends of movable rod 15 all extend to Outside the sliding hole, the front side wall of the movable rod 15 is provided with a second strip hole, and the fixed rod 12 is longitudinally arranged in the inside of the second strip hole, and the front and rear ends of the fixed rod 12 are fixed to the wall of the sliding hole. Connect, the two ends of the second spring 14 are respectively fixedly connected with the left side wall of the fixed rod 12 and the left side hole wall of the second strip hole, and the clamping plate 16 is vertically fixed with one end of the movable rod 15 near the electric push rod 5 connect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com