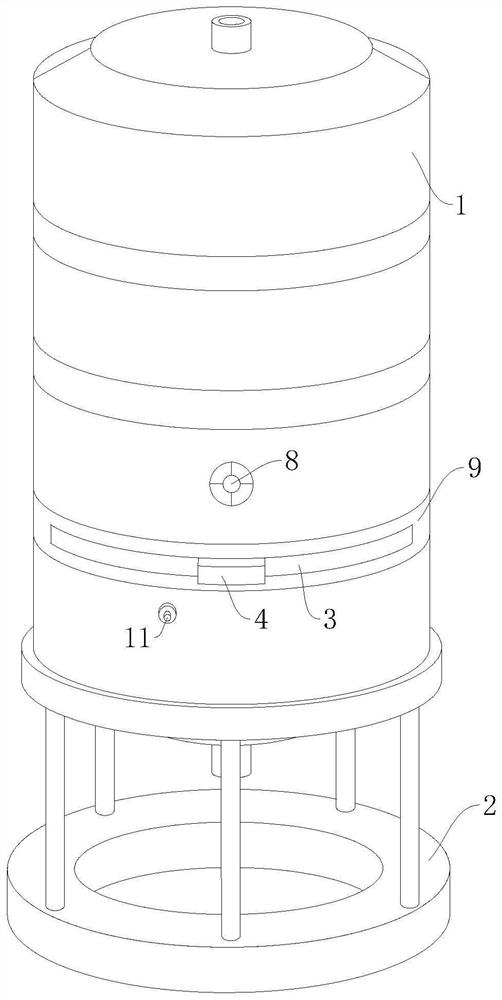

Separating tower for coal chemical industry

A separation tower and coal chemical technology, applied in the field of coal chemical industry, can solve the problems of waste of processing time, troublesome replacement of packing layers, and reduce the working efficiency of separation tower, etc., and achieve the effects of preventing waste, facilitating disassembly and installation, and improving utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

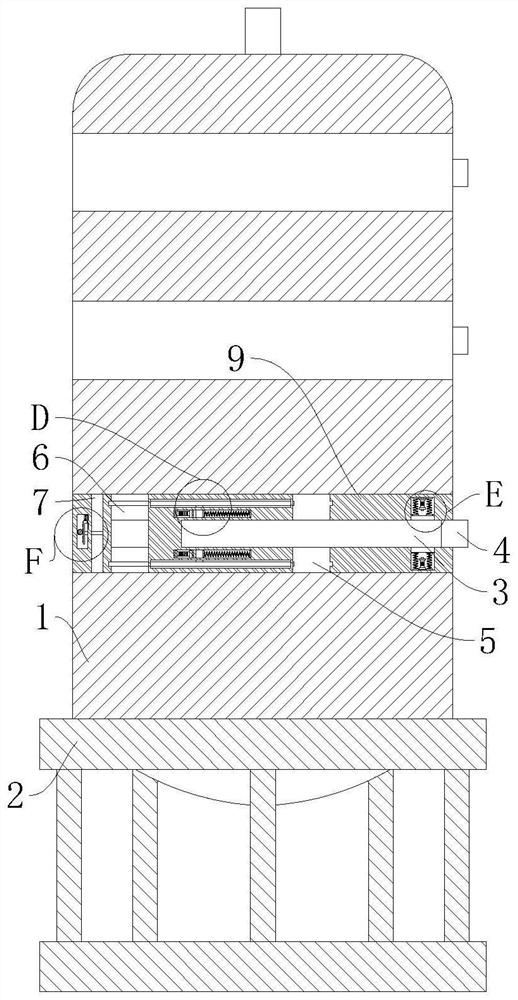

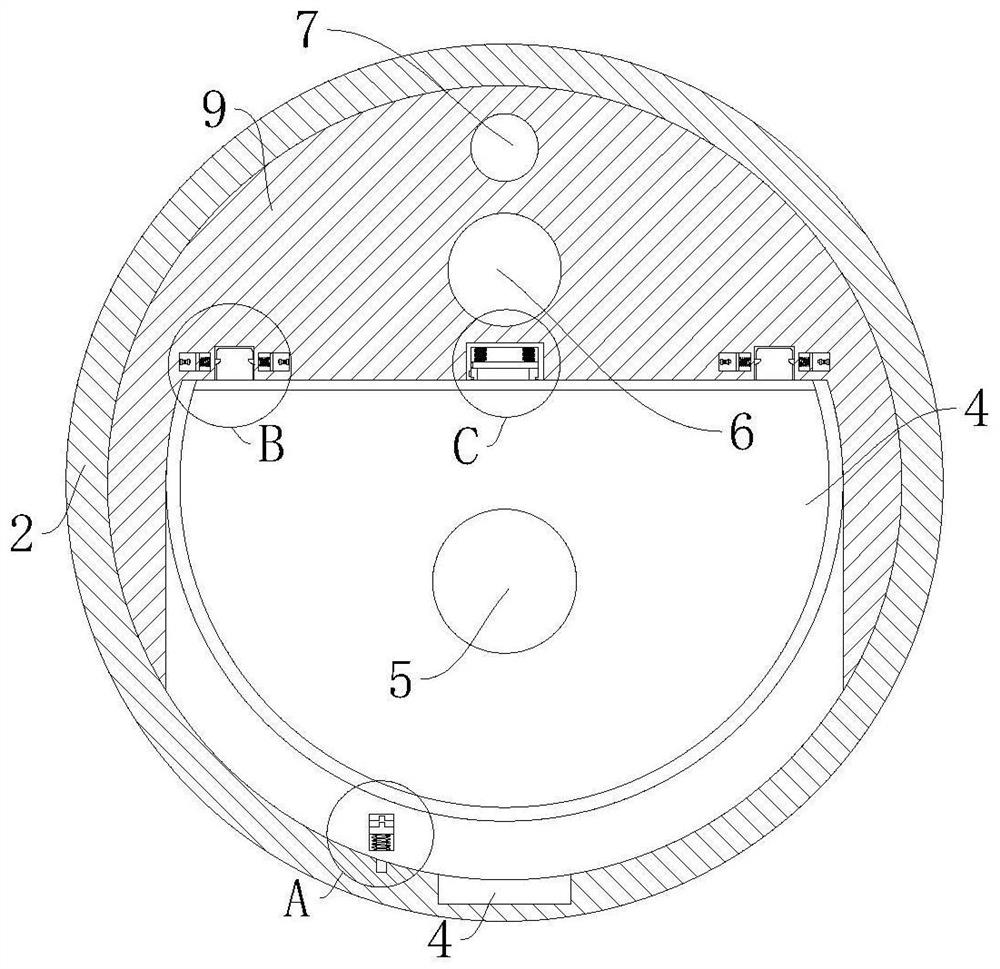

[0046] As an embodiment of the present invention, refer to figure 1 , both the upper and lower sides of the packing plate 3 are provided with sealing components, and the two sealing components are controlled by the control mechanism at the same time and move in the same direction.

[0047] In this way, when the packing plate 3 is replaced, the coal material at the upper end can be effectively prevented from leaking through the first exhaust hole 5 and the second exhaust hole 6 at the upper end. 3. The first exhaust hole 5 and the second exhaust hole 6 on the upper and lower sides are sealed, so that the separation effect of the separation tower can be improved.

[0048] As an embodiment of the present invention, refer to Image 6 , the opening and closing mechanism includes a pressing shell 24 fixedly installed inside the packing layer 9, a pressing plate 20 is movably installed inside the pressing shell 24, a third spring 21 is fixedly installed on the pressing plate 20 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com